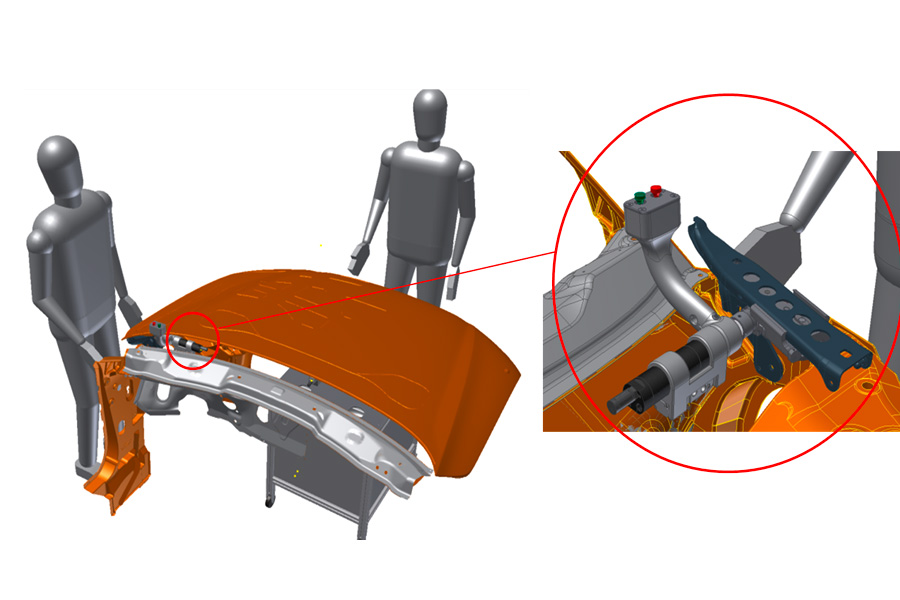

Tailgate

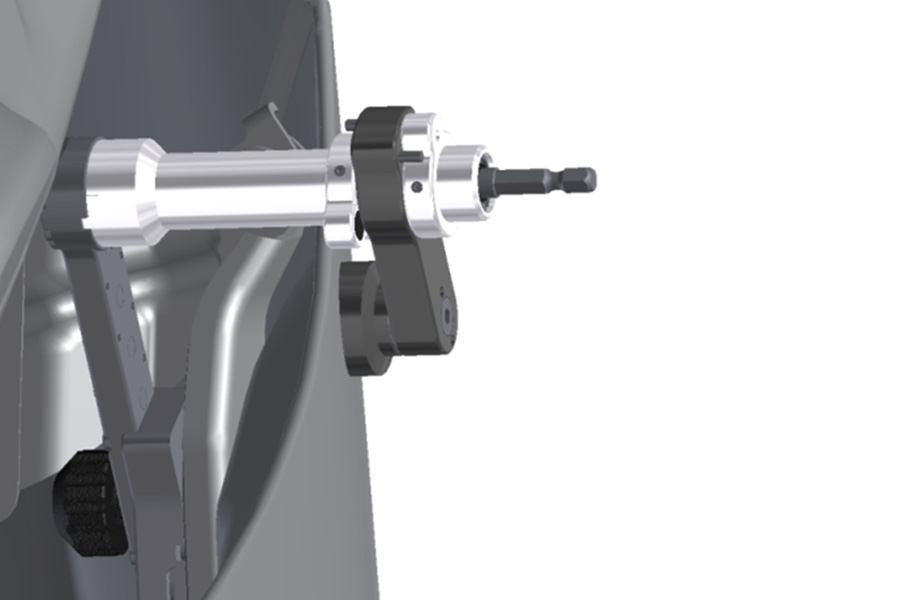

What is fastened?

- The hinge between the the tailgate and the chassis

What are the difficulties?

- The tailgate has to be fastened to the chassis in the closed position

- Parallel fastening in very tight space and high torque

- Complete fastening system including drives, fasteners

- The start must be actuated externally

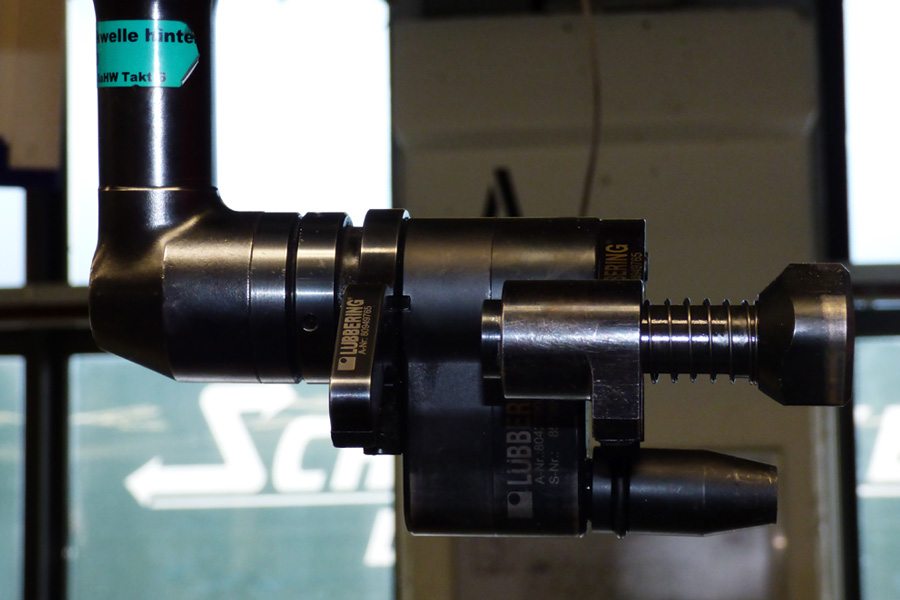

What is Lübbering‘s solution?

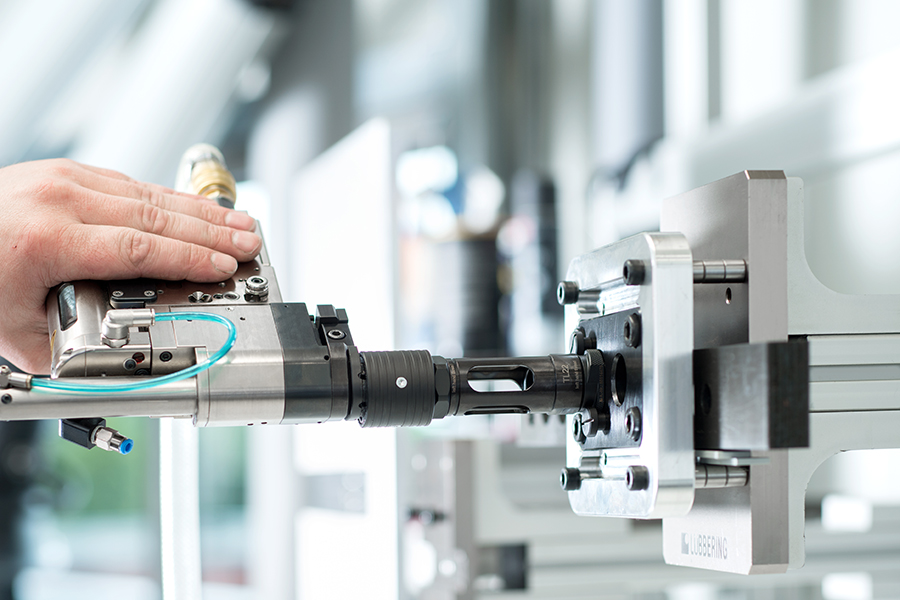

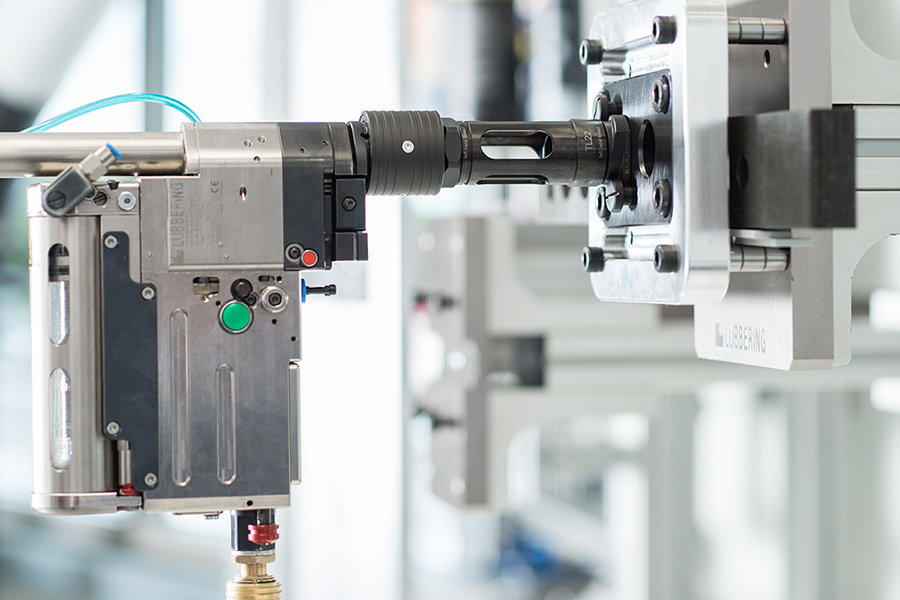

- Synchronised fasteners which are remotely and centrally controlled but separately fastened through pre-tightened torque

- Designing a fastening system which includes drives, gears and torque shutoff

Brake line

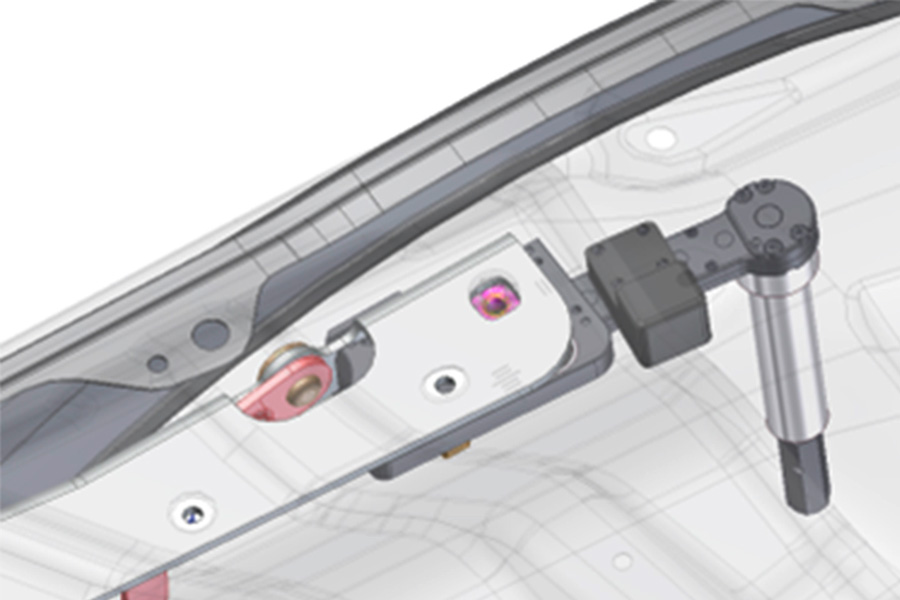

What is fastened?

- (A) Hydraulic brake line at Porsche 911 and Porsche Boxter

- (B) The brake line in the front and rear wheel arches at Porsche Cayenne

- (C) Fastening on the underside of the car

What are the difficulties?

- (A) The access is difficult and tight space

- (B) Poor visibility for the worker and safe fastening: A-fastening

- (C) Holder is essential | the fastener must be held in position, as it cannot be attached to the car

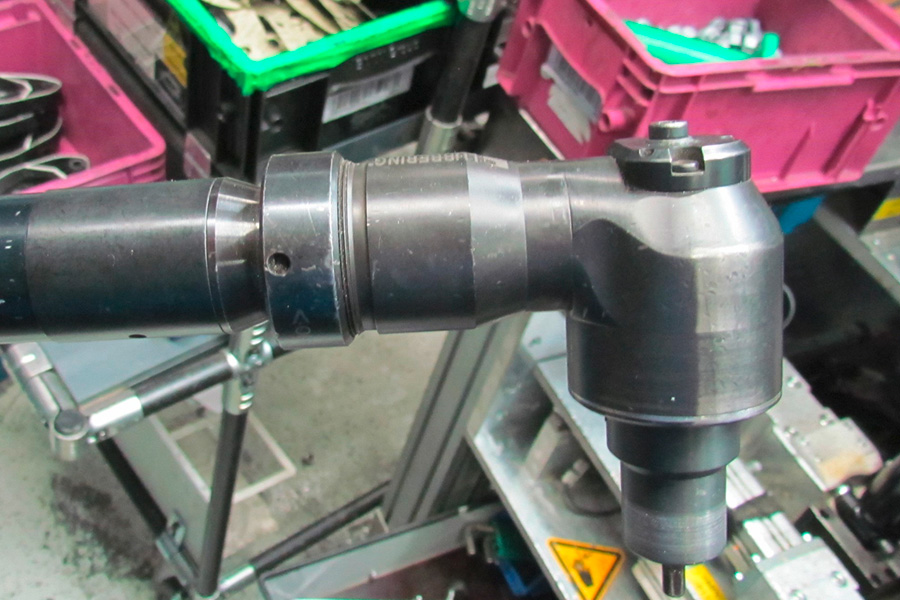

What is Lübbering‘s solution?

- (A) 4-stage Inline geared offset head for best access to the fastening application in combination with an Atlas Copco EC-Tool which will provide the correct torque

- (B) The smallest possible geared offset head with maximum performance and high repeatability

- (C) The separation point is fastened in one step with an open geared offset head with a sliding holder

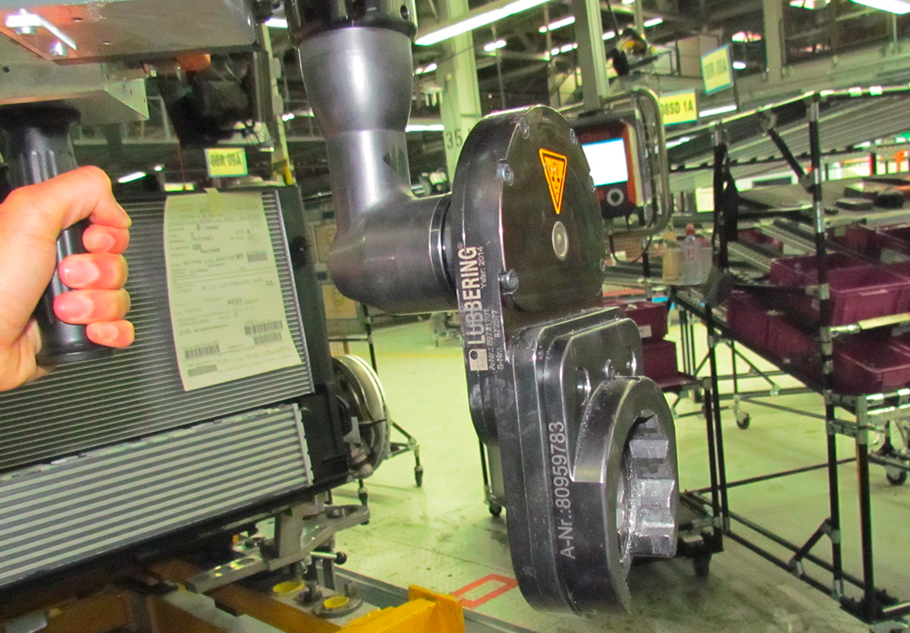

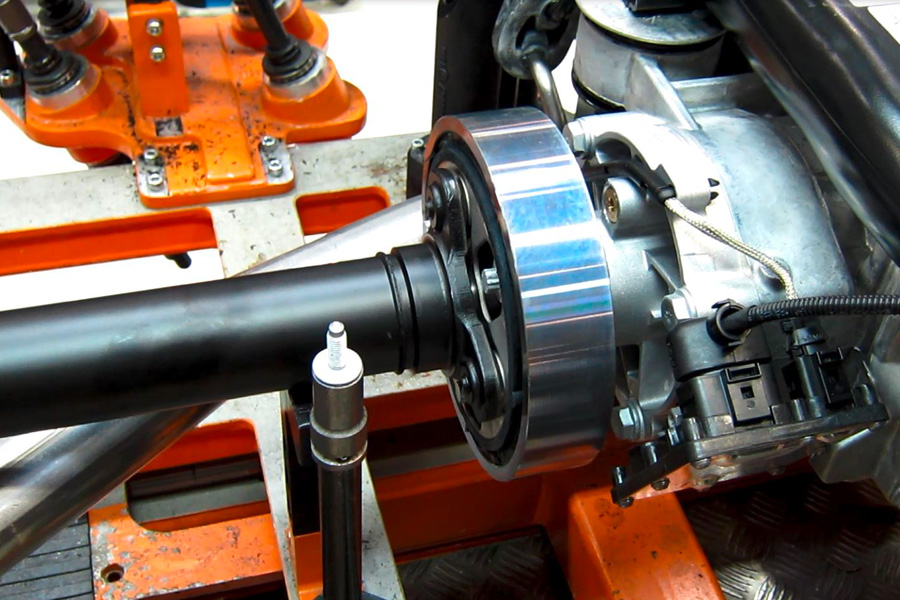

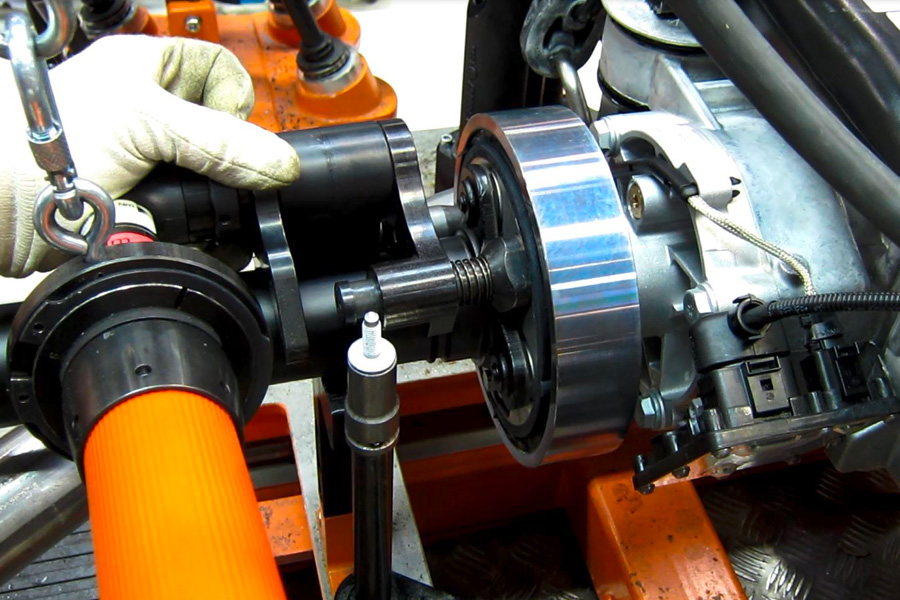

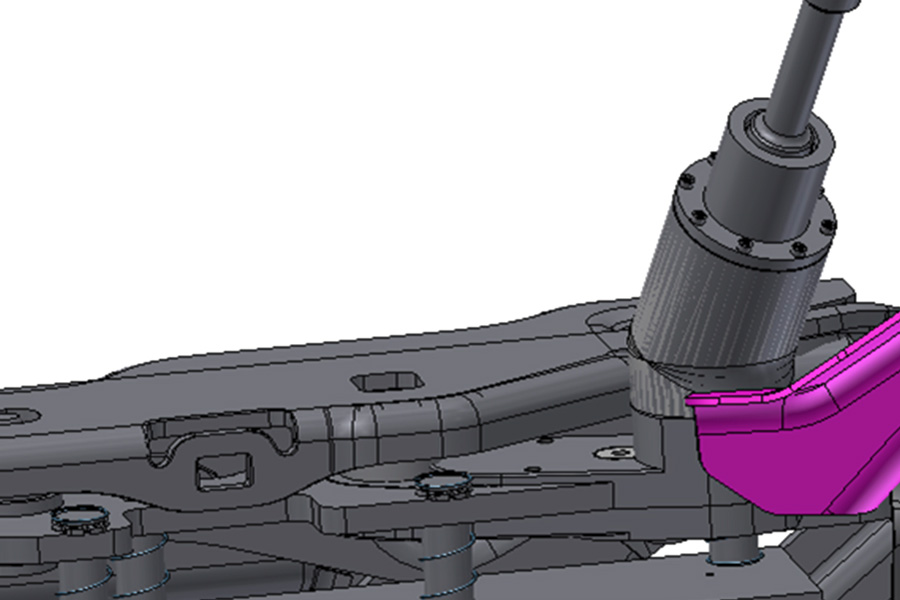

Cardan shaft

What is fastened?

- Cardan shaft flange in the front and back

What are the difficulties?

- Reinforcing and centering the torque on the cardan shaft

What is Lübbering‘s solution?

- 2 variants for cardan shafts for the front and back

- Geared offset head with swivelling holder which avoids the twisting of the cardan shaft when applying the torque

- Additionally, the machine operator can keep on turning the cardan shaft with the fastening system to reach the next fastening position

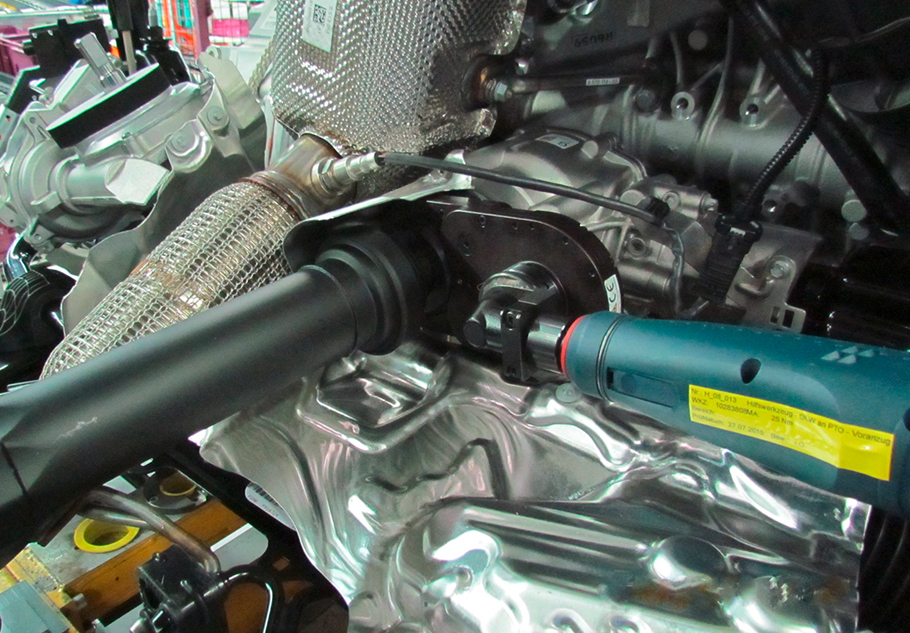

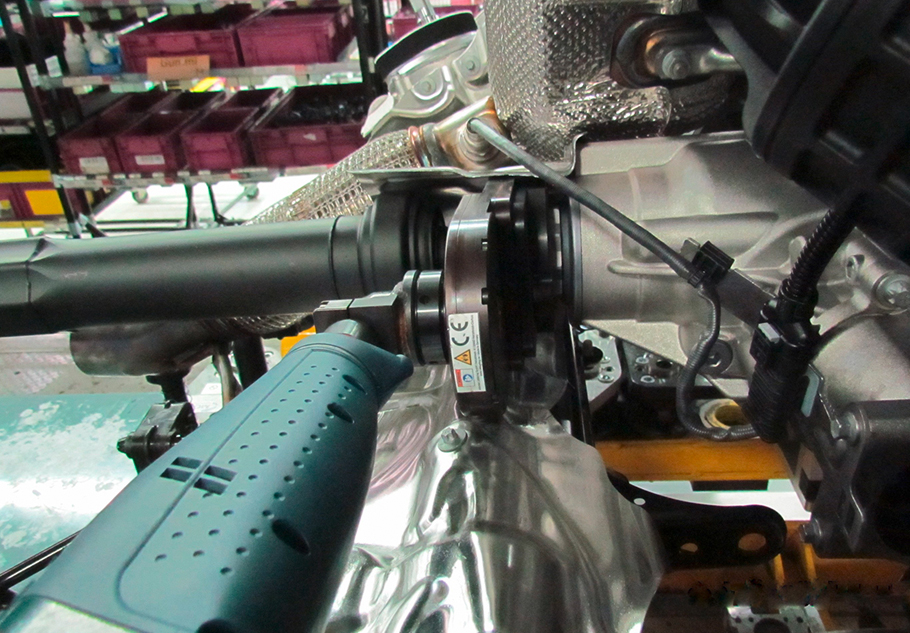

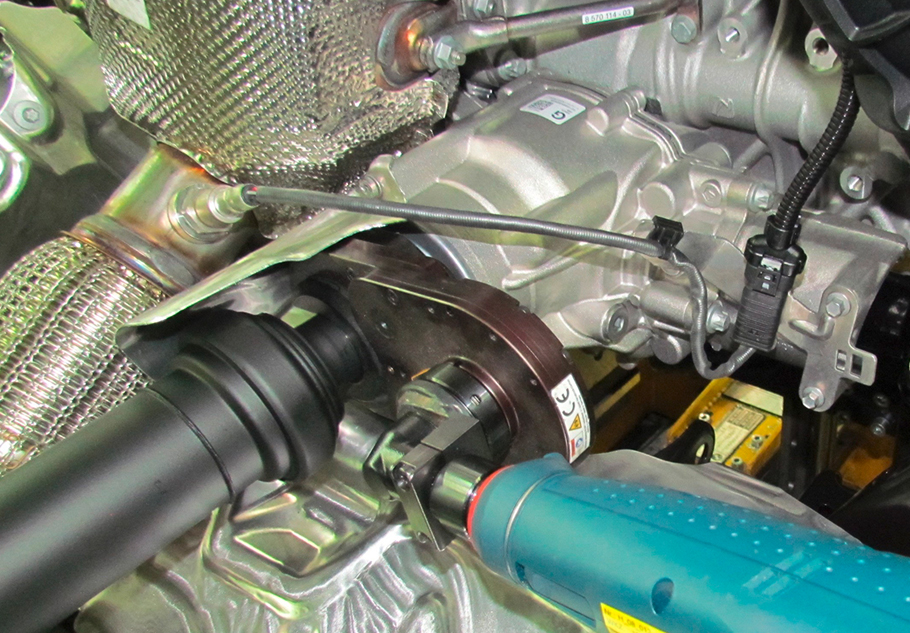

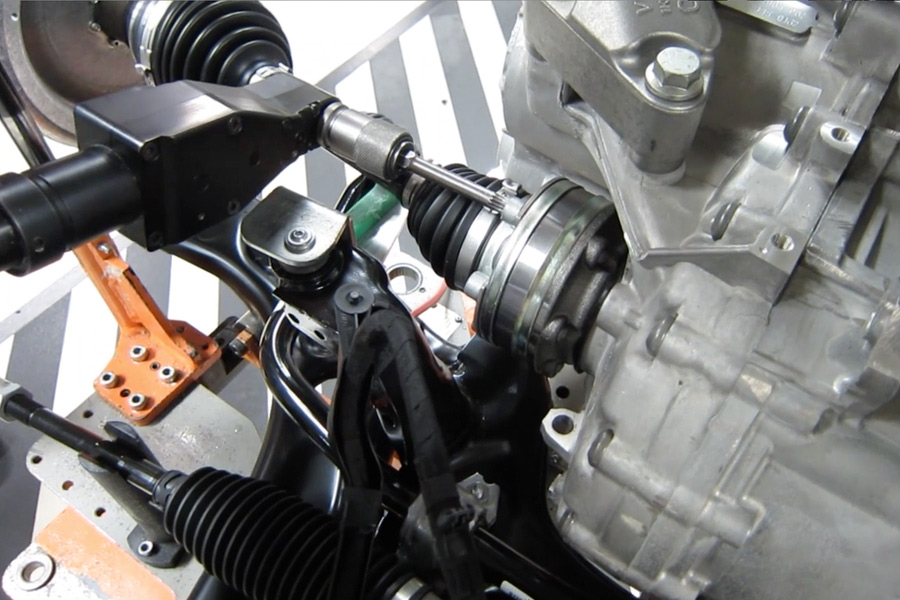

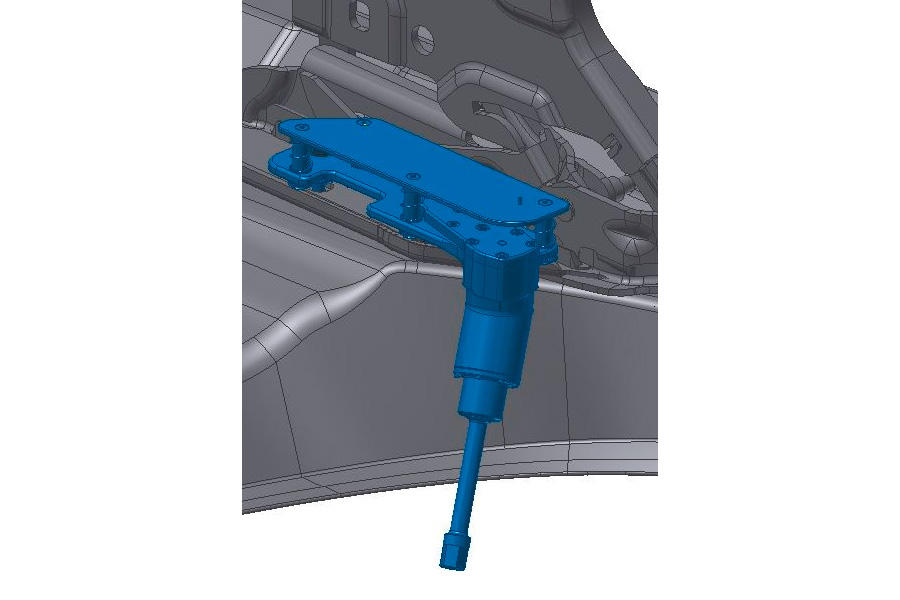

Drive shaft

What is fastened?

- (A) The central screw on the cardan shaft

- (B) Flange cardan shaft (is fastened to the gearbox with several (6 to 8) fastenings per side)

What are the difficulties?

- (A) Central nut with extrem large width across flats | the nut is fastened to the left | Accuracy required by the customer: +/- 10 %

- (B) Critical fastening access and angle fastening with high end torque

What is Lübbering‘s solution?

- (A) Open geared offset head with holder (A/F 50 / A/F 64) | Accuracy of the geared offset head: +/- 7,22% | capable of 100 Nm

- (B) Inline geared offset head with insert for bit extension to improve access | output torque of 100 Nm at minimal radius

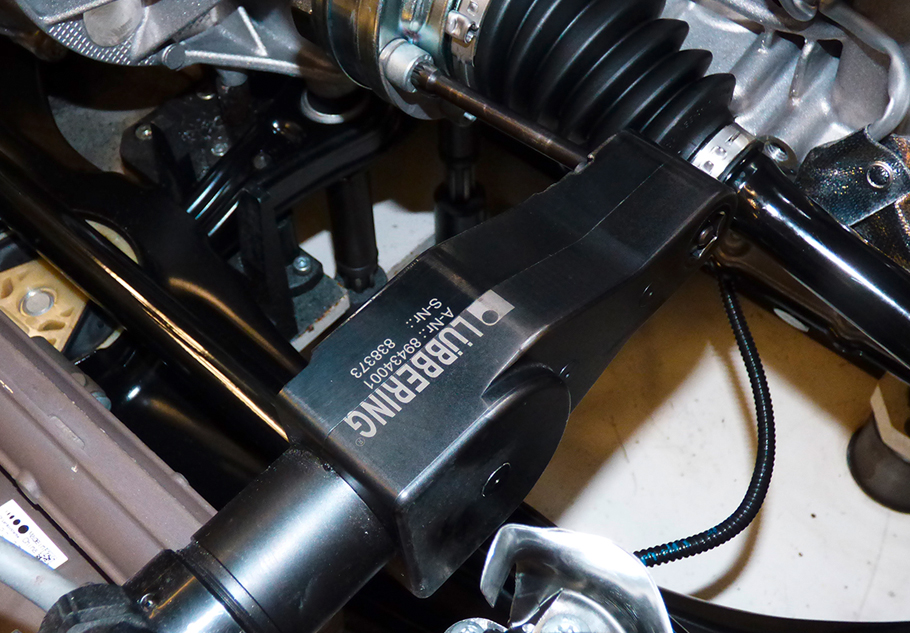

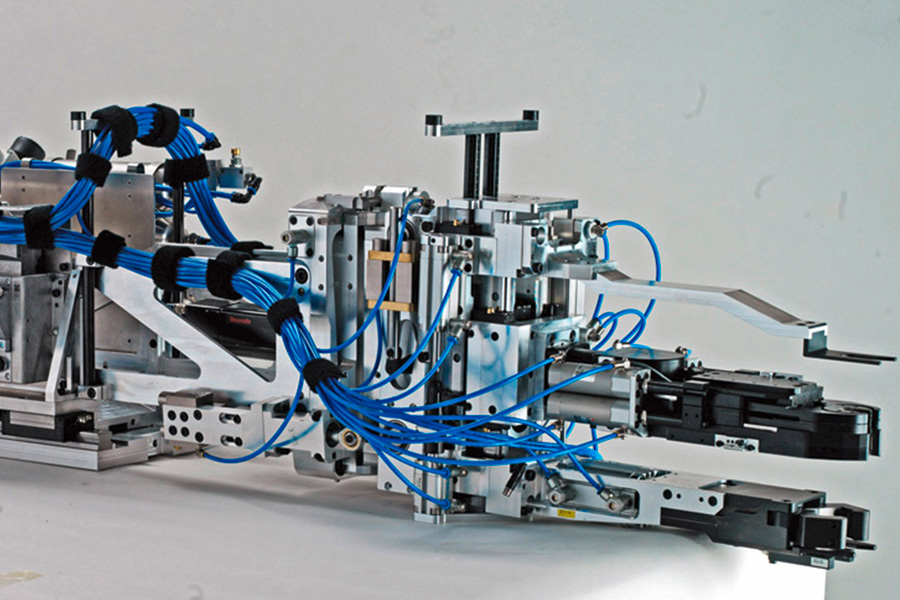

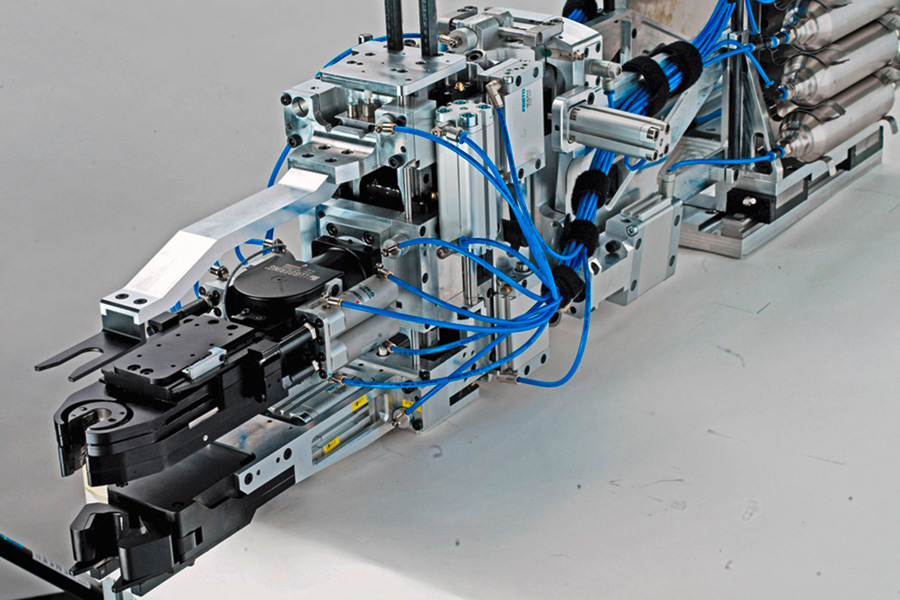

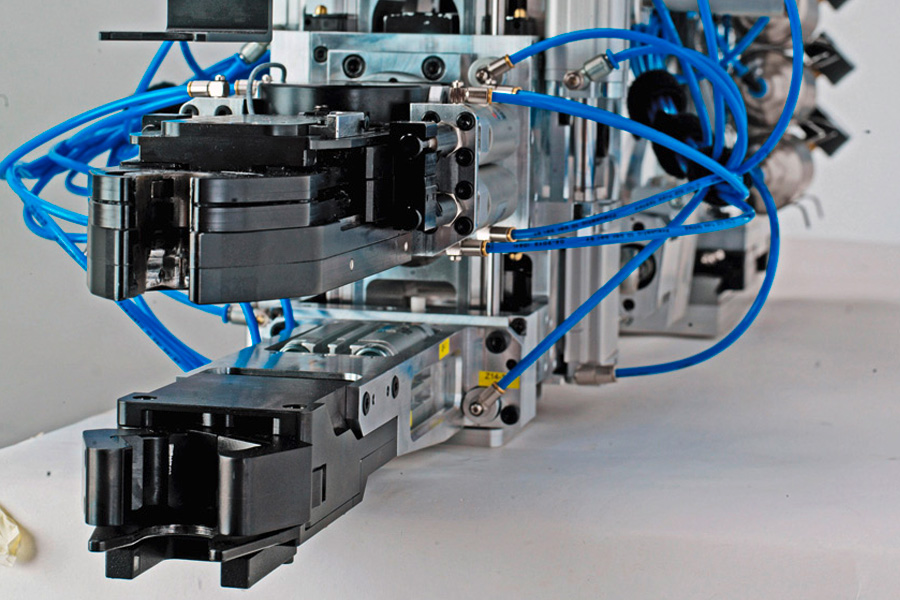

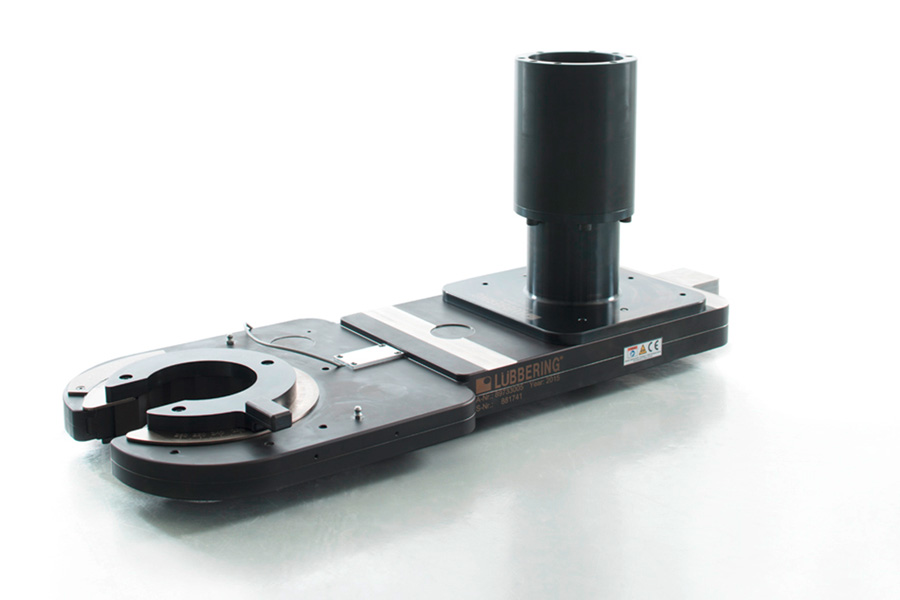

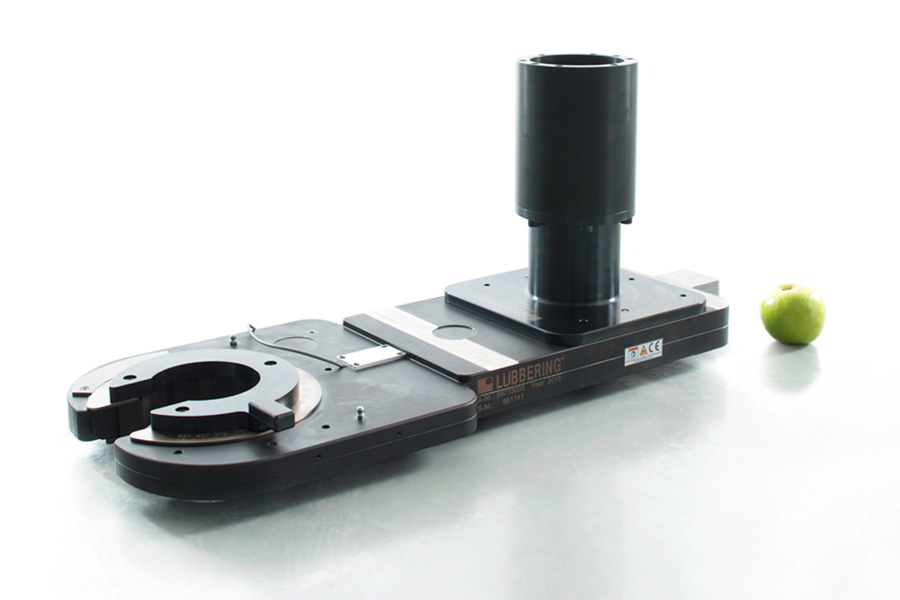

Track setting

What is fastened?

- Steering track-rod

What are the difficulties?

- Track-rod must be removed, adjusted and refastened

- Two different track-rods with different widths across flats

- Consistent, lasting accuracy during the process is required

What is Lübbering‘s solution?

- Complex special design of the track setting tool

- Opened geared offset head with a multiple function output socket gear

- To achieve a „swimming“ installation of all components to ensure operation from every angle

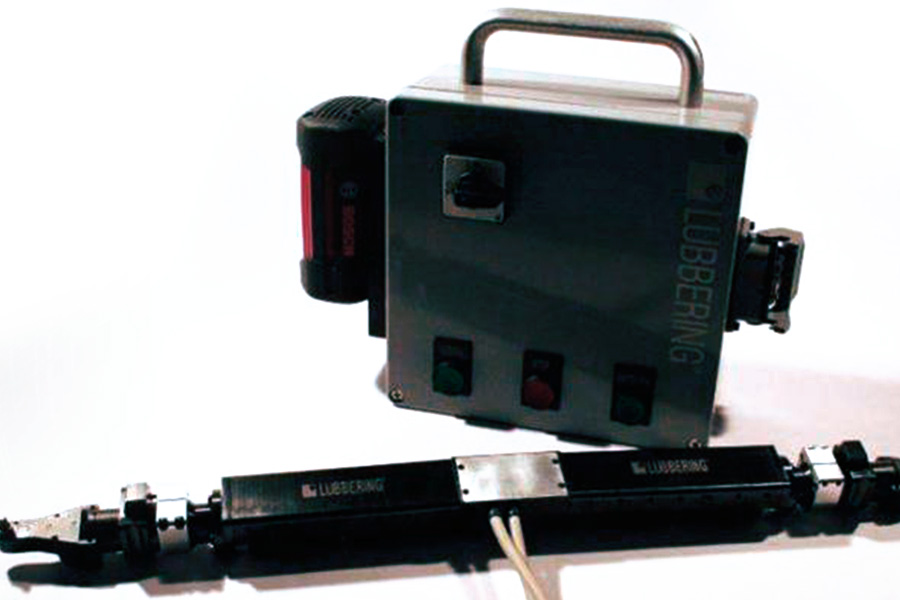

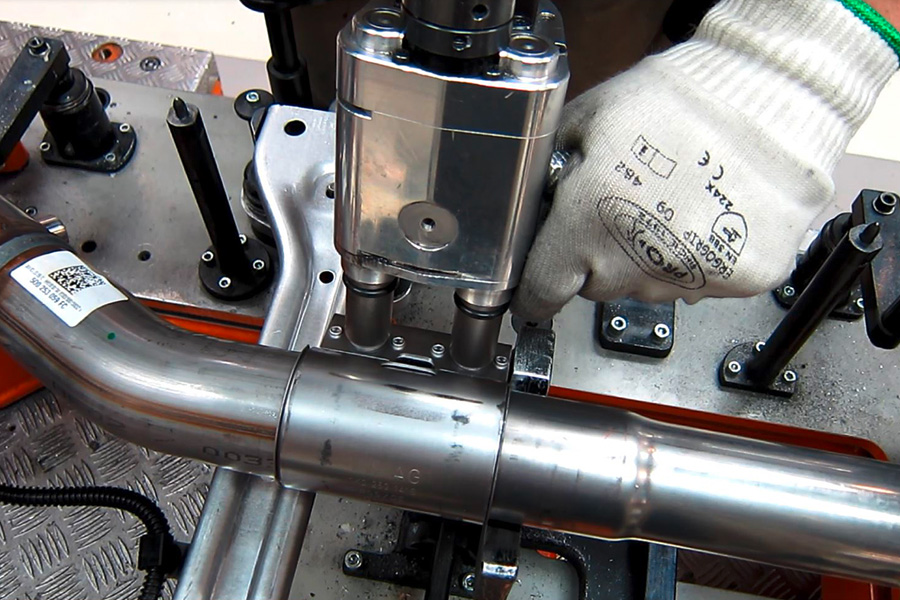

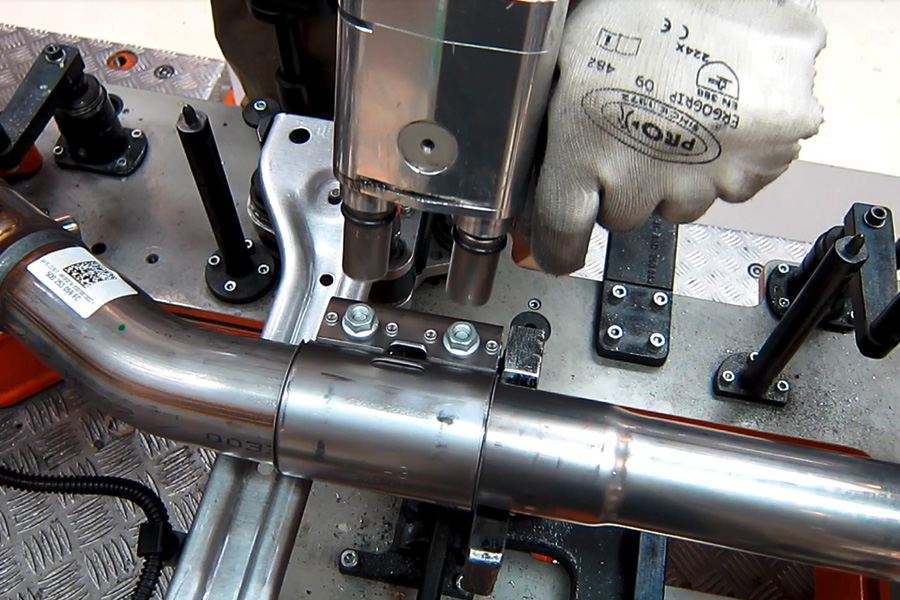

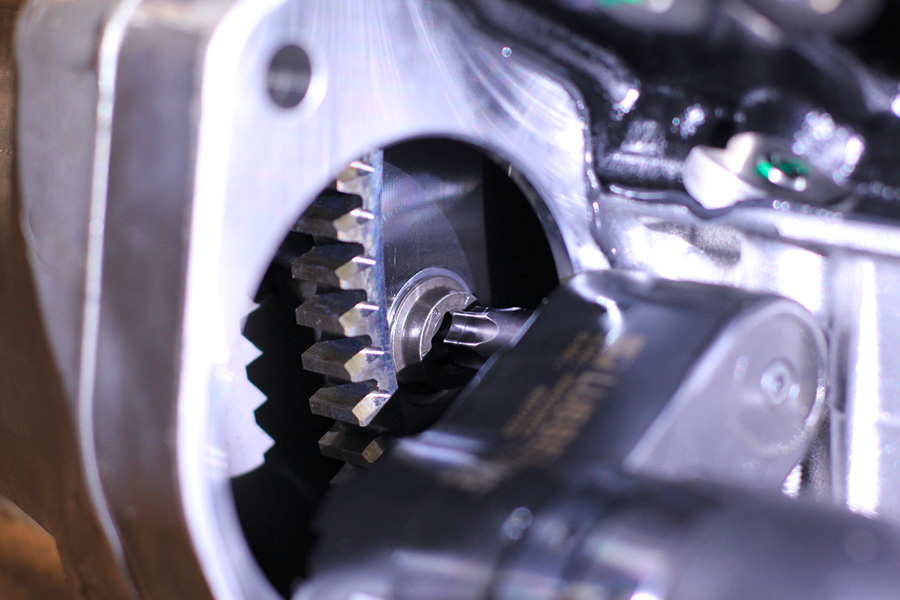

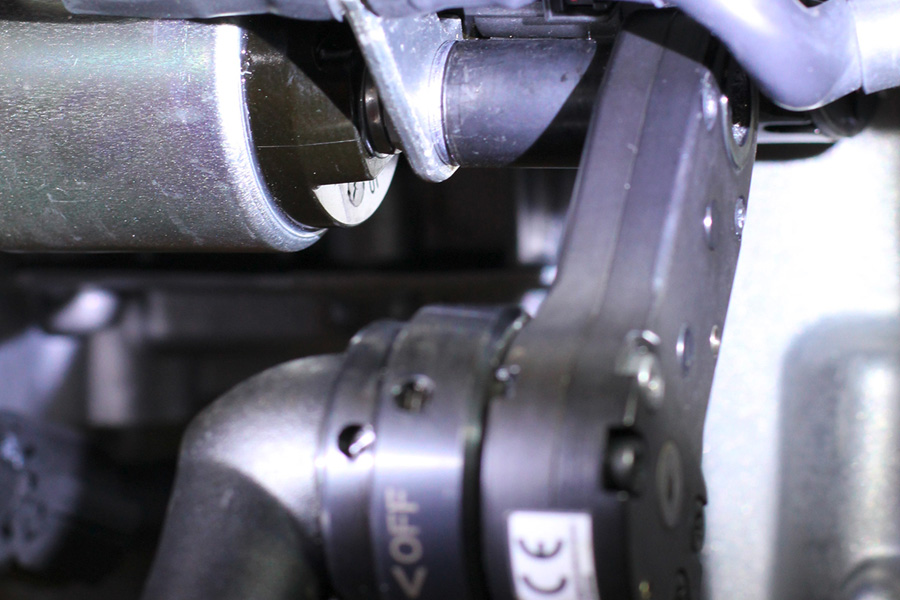

Exhaust system

What is fastened?

- Clamps on the exhaust system with two screws

What are the difficulties?

- Fastening both screws simultaneously

- One tool has to drive two outputs (torque must be 50-50)

What is Lübbering‘s solution?

- Complete redesign of the differential gear

- Special fastening system with differential gear

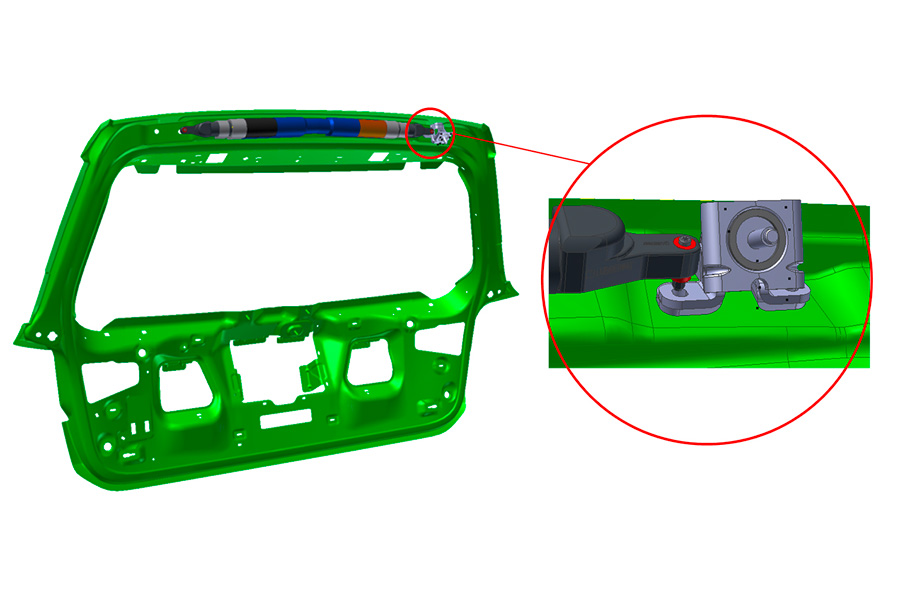

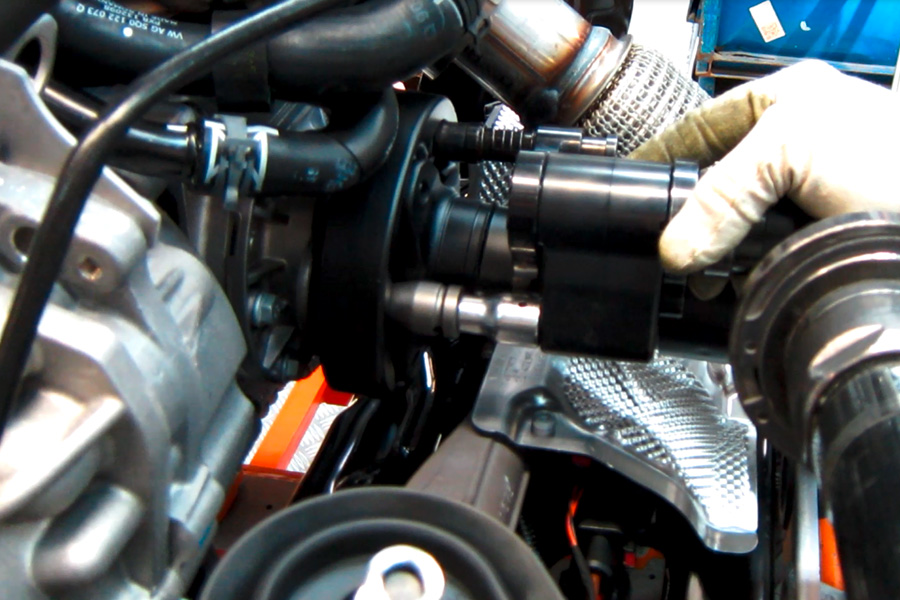

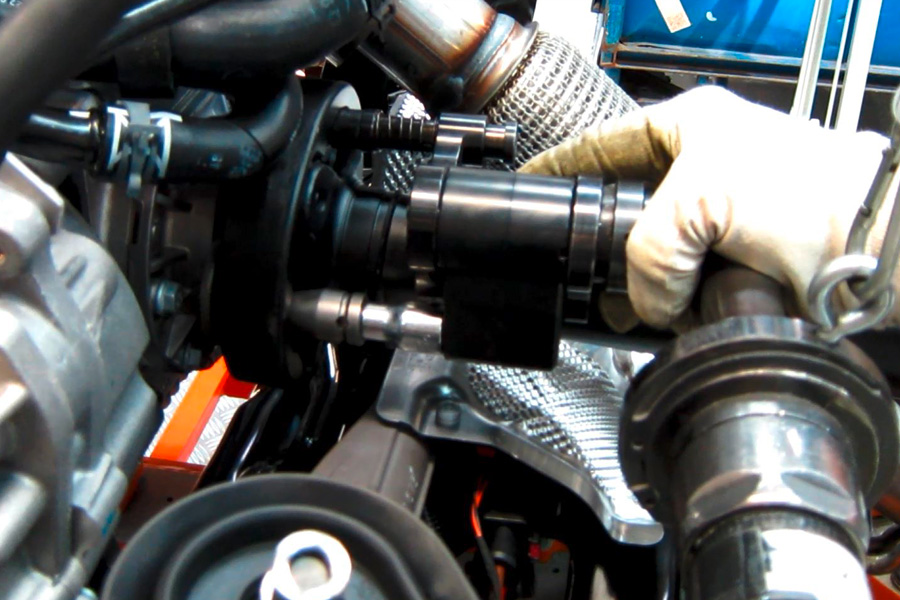

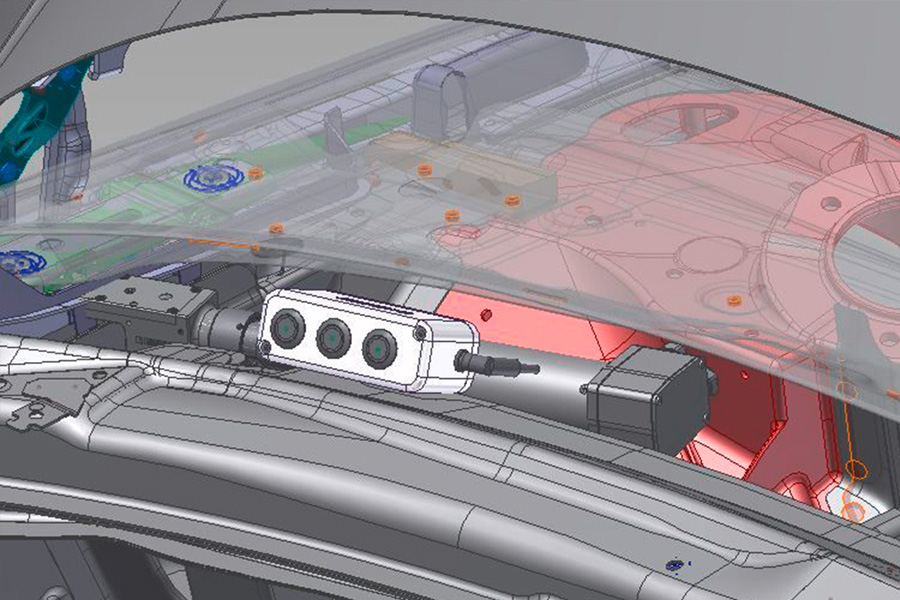

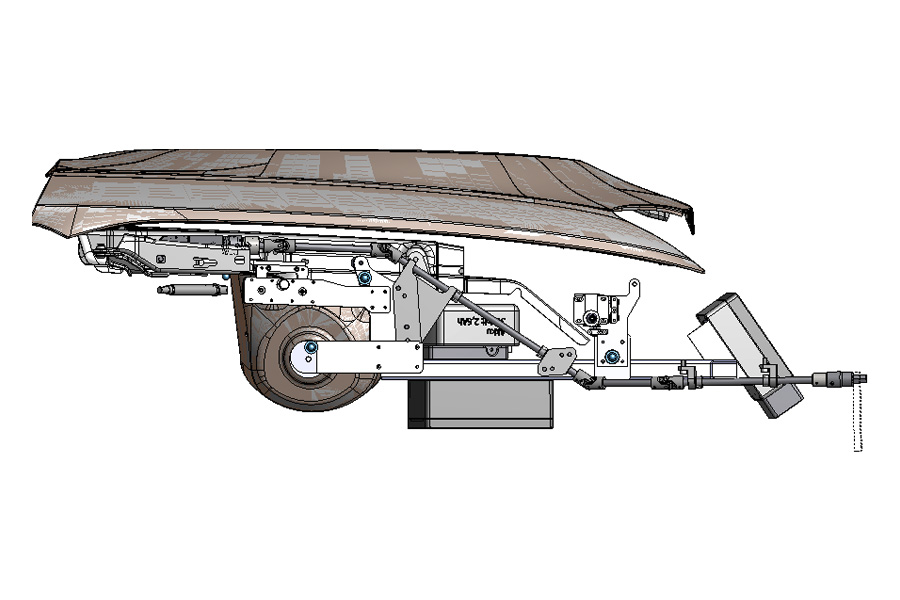

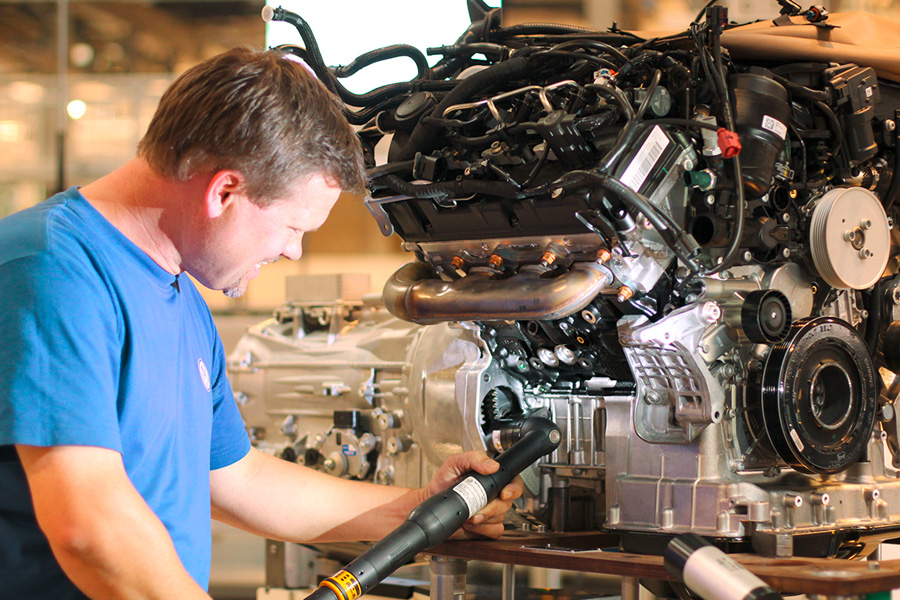

Front flap

What is fastened?

- The front flap at the hinge

What are the difficulties?

- Critical access in the engine block

- Has to be fastend in closed room due to gap measurement

What is Lübbering‘s solution?

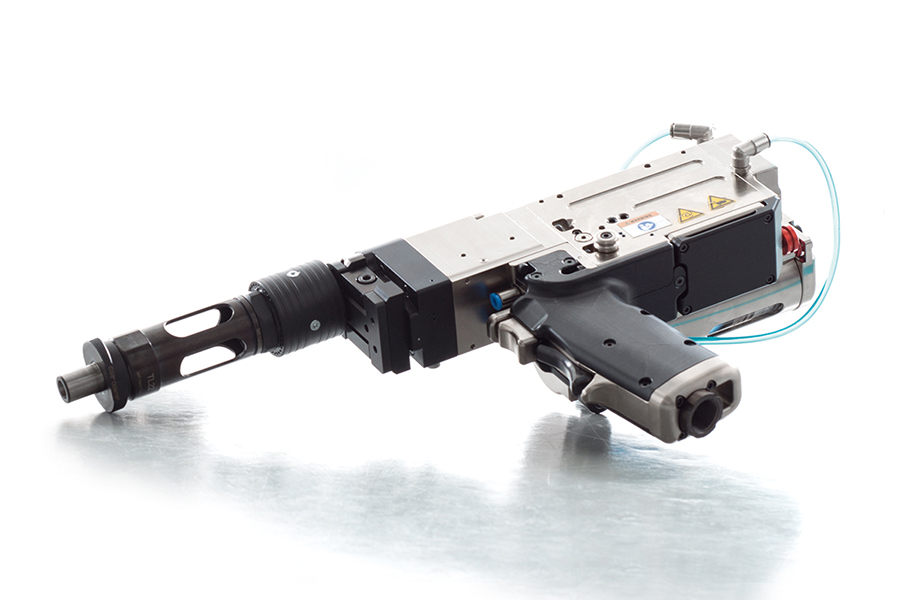

- Fastening sytsem consisting of Special-Line, adapter, output socket, nut, drive motors and control system

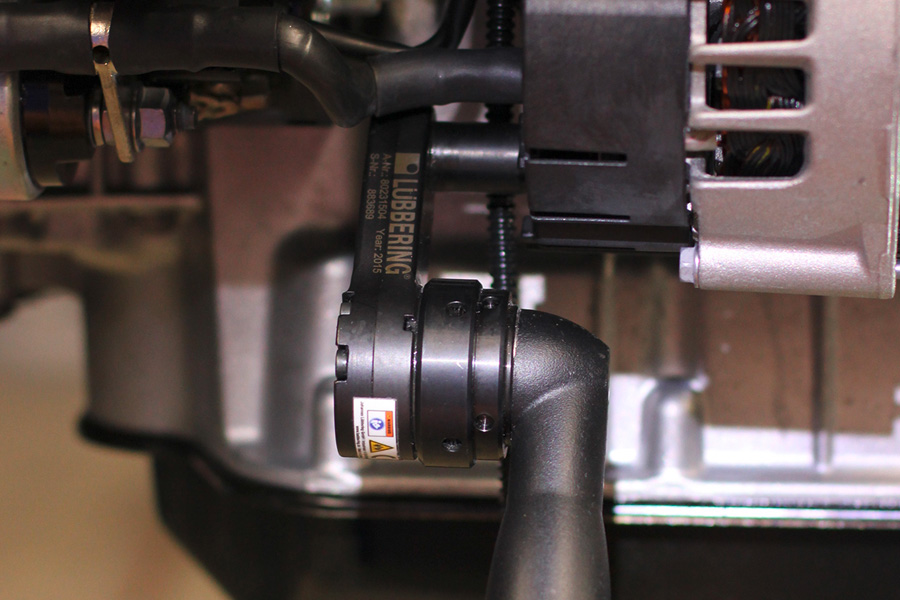

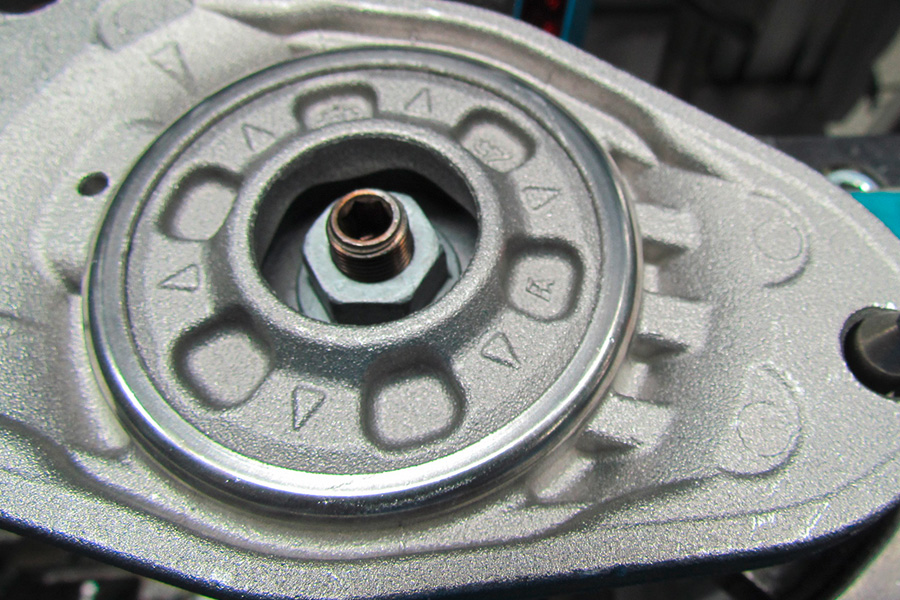

Roll stabiliser

What is fastened?

- The central screw on the roll stabiliser

What are the difficulties?

- Large widths across flats (82mm & 110mm)

- Readjustment of the output socket profile through an adjustment ring must be possible

- The fastening process takes places on a measuring bench

- The geared offset head housing must also serve as a measuring tool

What is Lübbering‘s solution?

- Opened geared offset head with an output torque of 500 Nm

- Measuring scale on the output socket gear

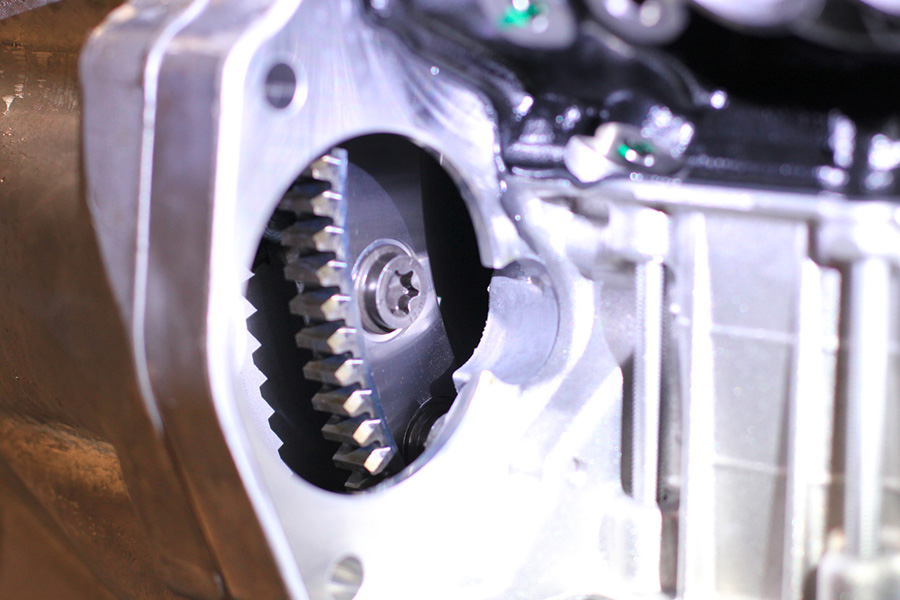

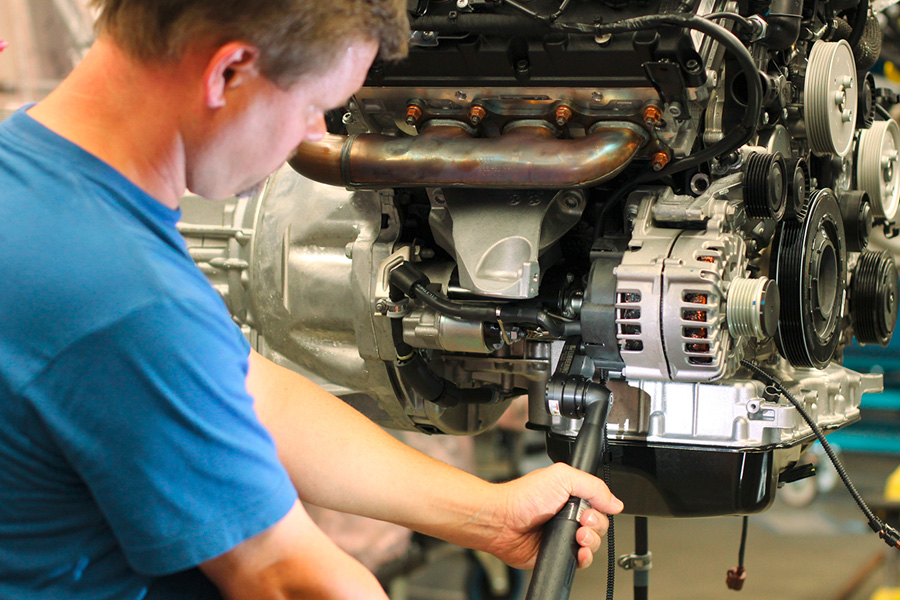

Engine

What is fastened?

- (A) Ground cable at Porsche Cayenne

- (B) Converter fastening at Porsche Cayenne

What are the difficulties?

- (A) Limited space and highest safety requirements: A-fastening

- (B) Difficult to see the fastening Position | maximum torque from minimum size of geared offset head

What is Lübbering‘s solution?

- (A) Geared offset head from our standard range

- (B) Special geared offset head is designed to provide the worker with optimum view | Geared offset head for pre- and end-tightening

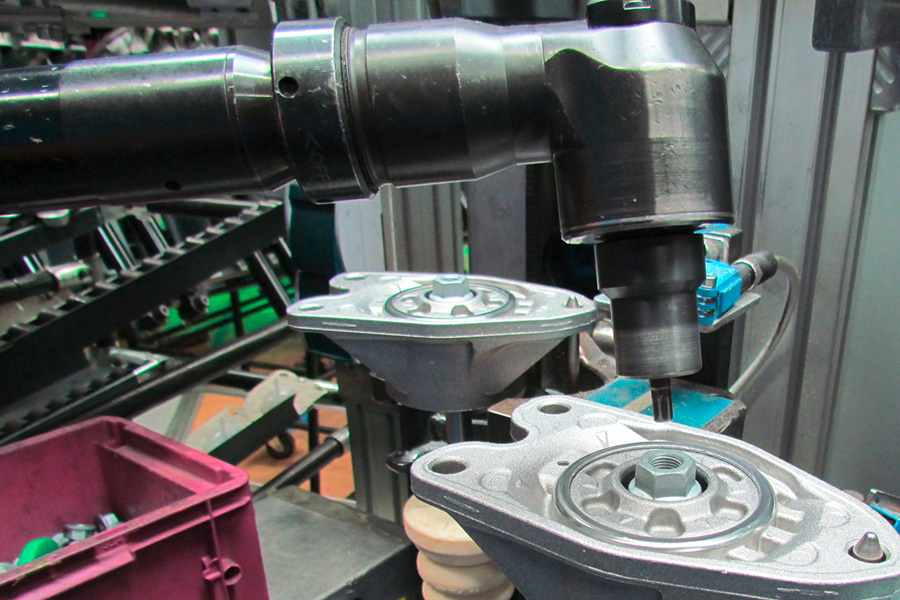

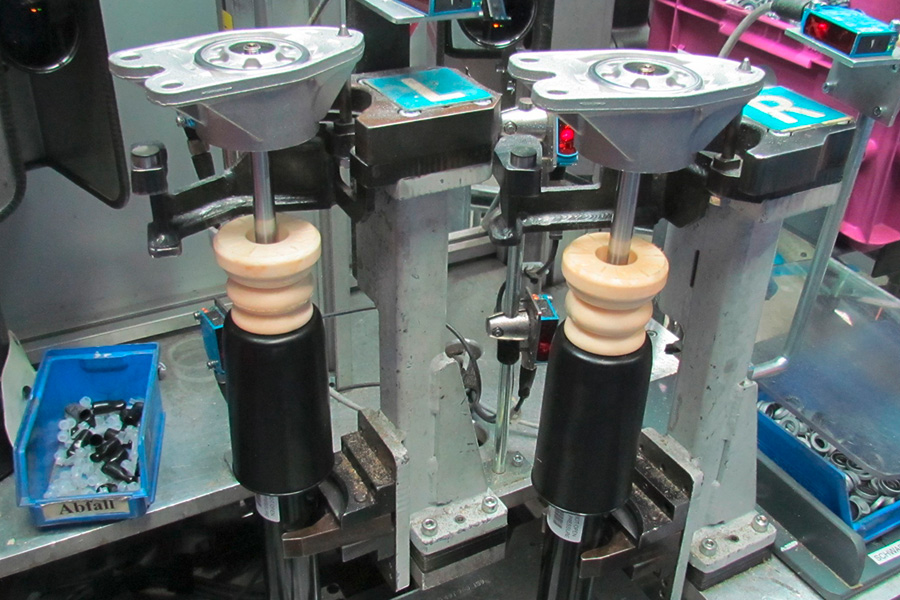

Damping rod

What is fastened?

- Damping rod with 38 Nm

What are the difficulties?

- Hold and drive is necessary because otherwise the fastened „head“ of the damping rod will twist with the suspension strut

What is Lübbering‘s solution?

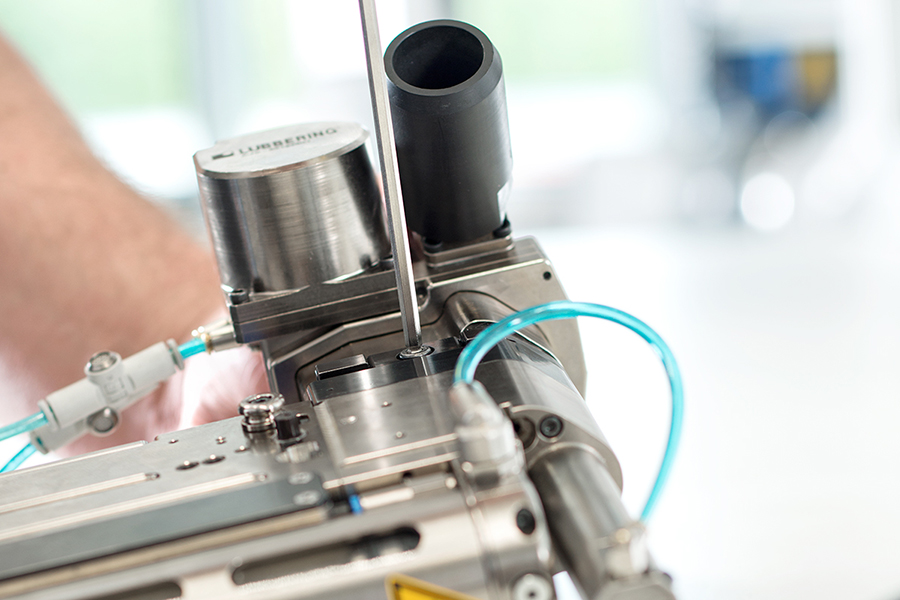

- Hold and drive angle head | Fastening tool as emergency strategy with Bosch battery tool

Fuel line

What is fastened?

- Fuel line in the engine bay / bulkhead at Porsche Cayenne

What are the difficulties?

- Limited Access

- Line must not twist during the fastening process

What is Lübbering‘s solution?

- The smallest possible geared offset head with integrated manual holder

- Compact and light design

- Minimum weight improves the handling experience of the worker

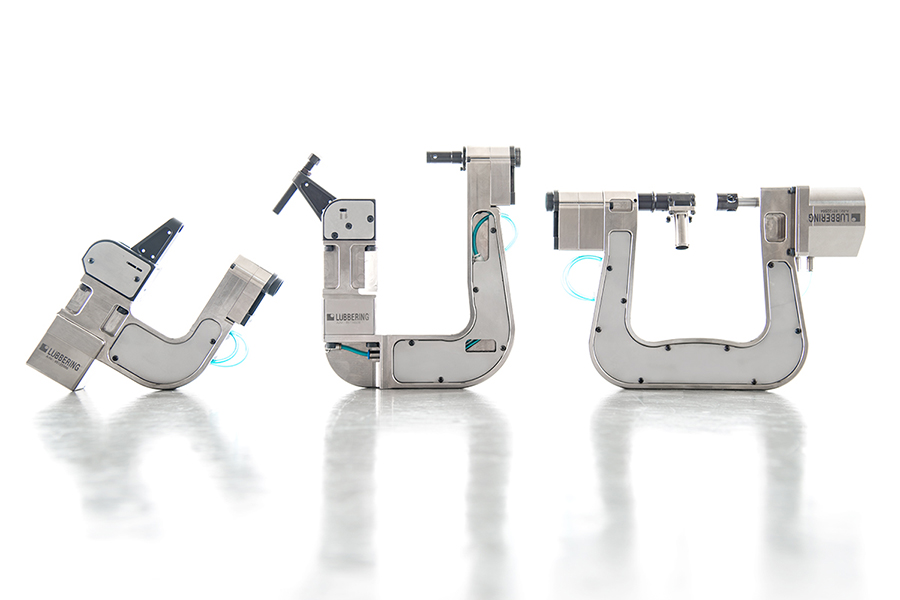

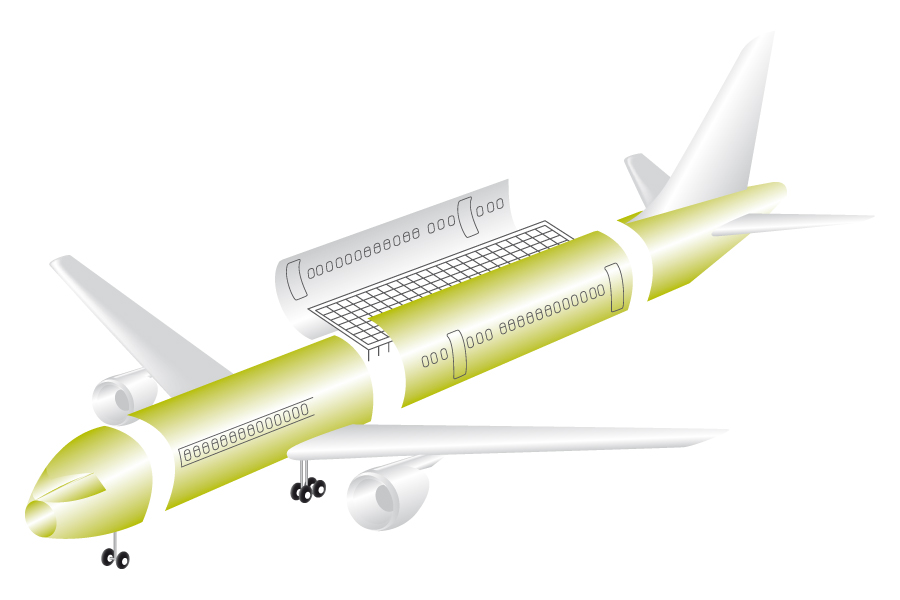

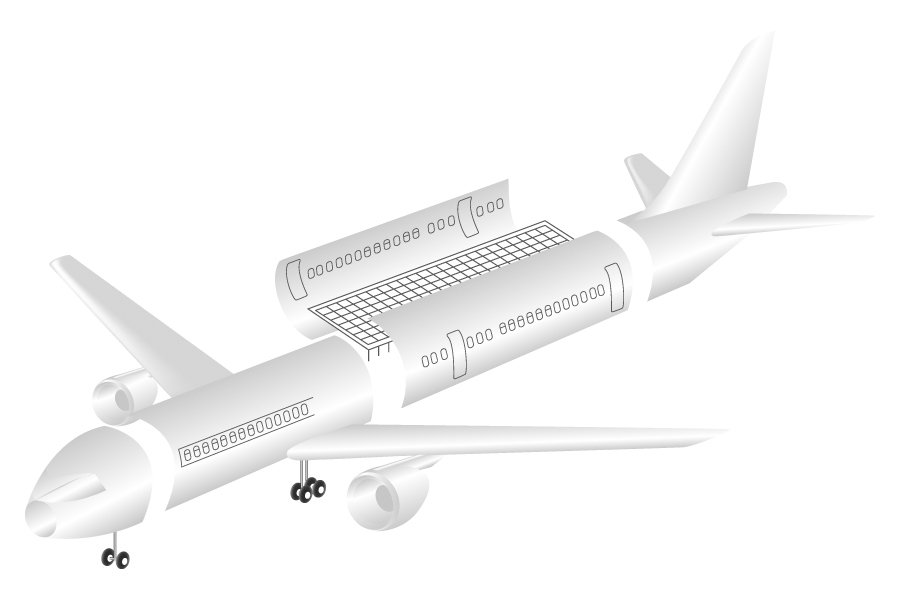

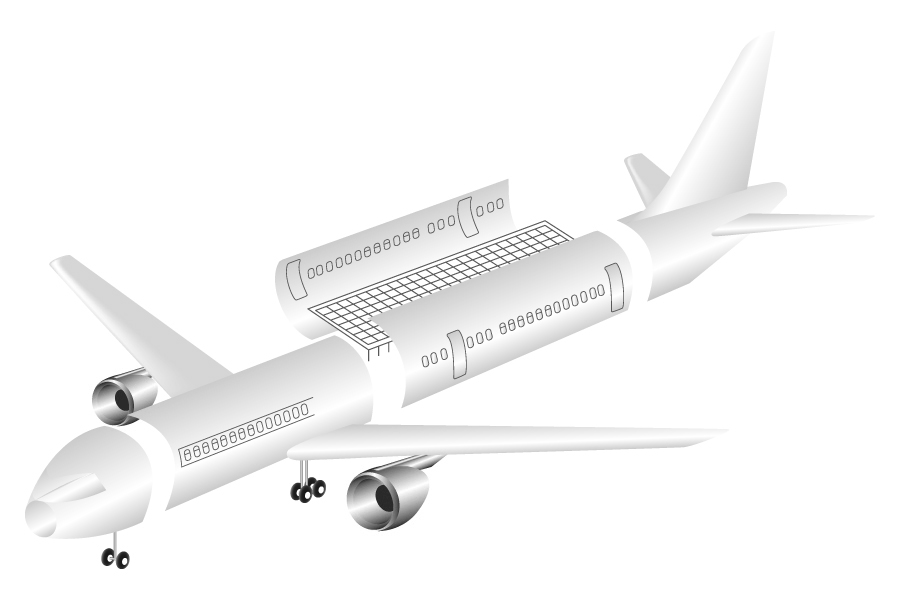

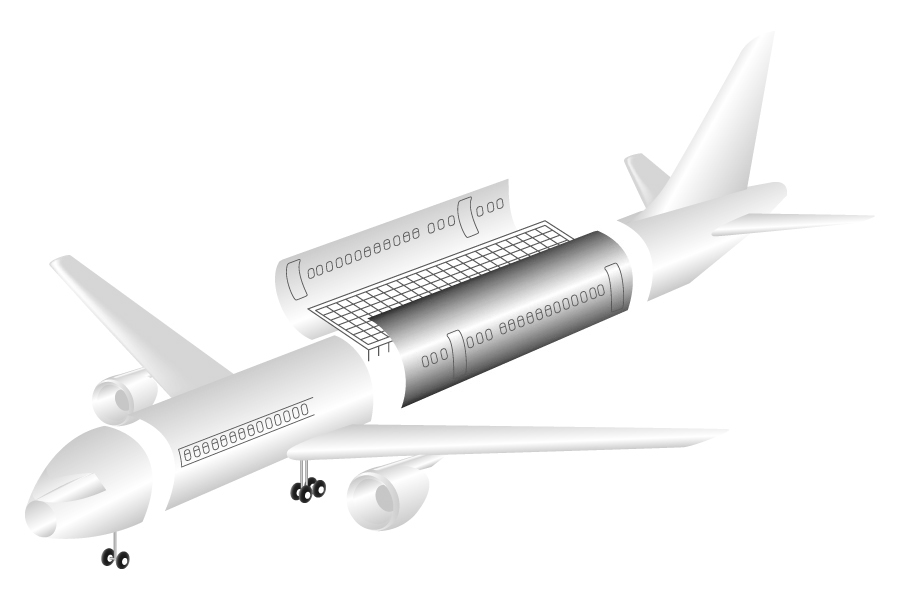

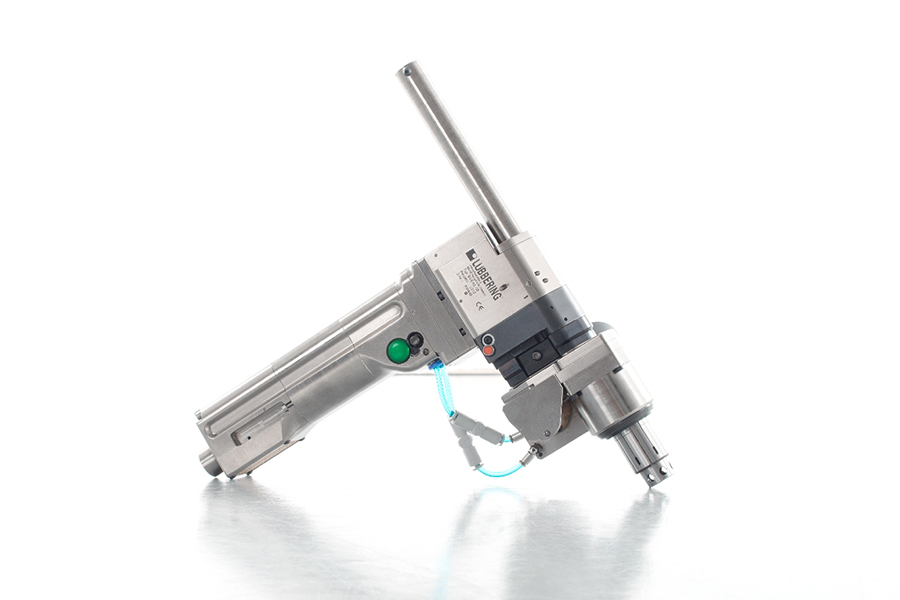

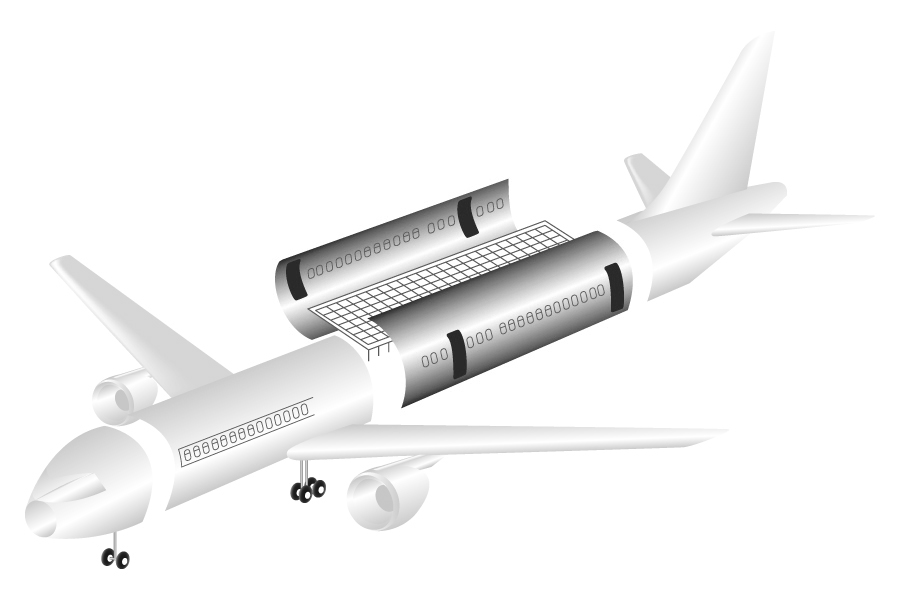

In the most different sectors

The drilling units and fastening systems of LÜBBERING can be used in the most different sectors. So you can see the LÜBBERING tools in the fields of aerospace, medical engineering, transport technology or in the shipbuilding.

LÜBBERING is already First Tier Supplier of well-known automotive and aircraft manufacturers and gives therefore numerous application examples for the two sectors, automotive and aerospace.

Sectors of application:

- Automotive: Fastening in heavily accessible points in the car

- Aerospace: Drillings into aircraft parts for the aeroplane assembly

- Shipbuilding: Drillings into ship components

- Medical engineering: Implants, artificial limbs

- Sports: Bicycle frames

Simply click on the different pucks on the car or aeroplane and convince yourself of LÜBBERING’s fastening and drilling solutions. On the one hand you see the difficulties in fastening or drilling and on the other hand the solutions we have realized.

Should you have any questions concerning the individual application examples do not hesitate to contact us.

Have fun on discovering.

Keriman Dindar

Phone: +49 (52 45) | 83 09 – 153

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

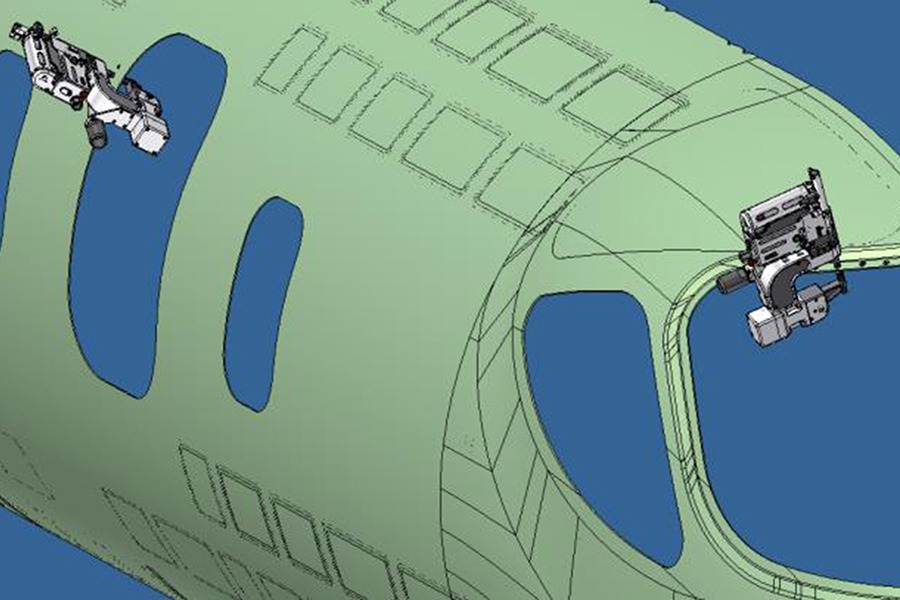

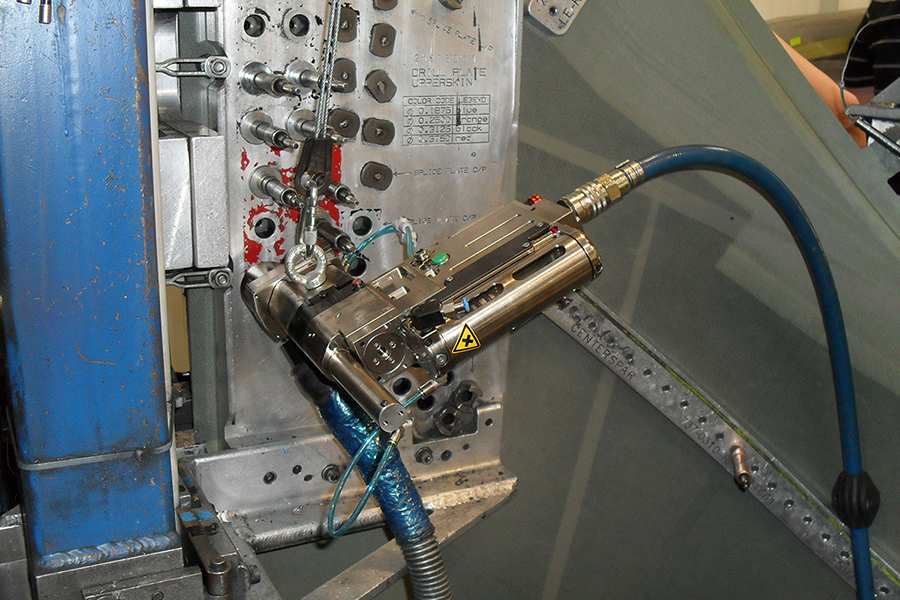

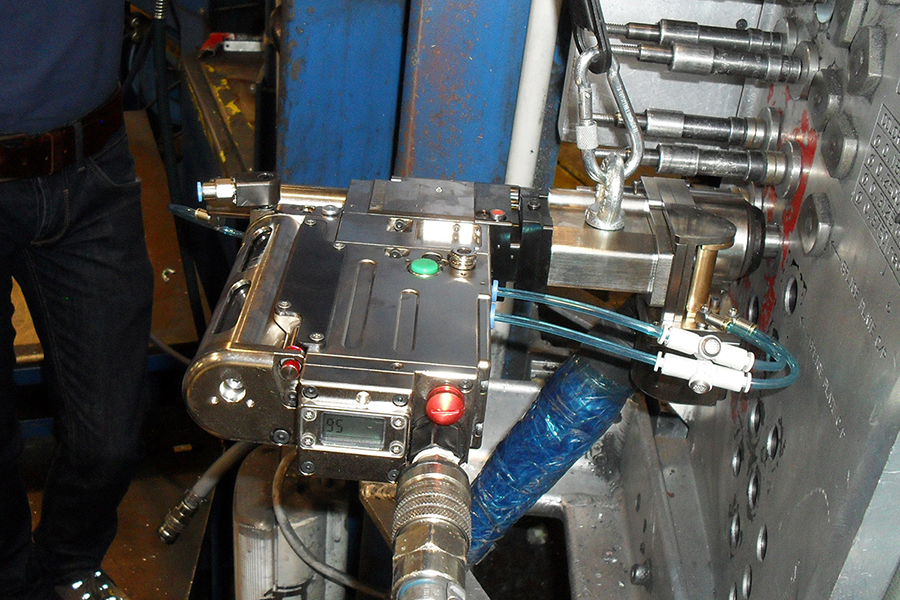

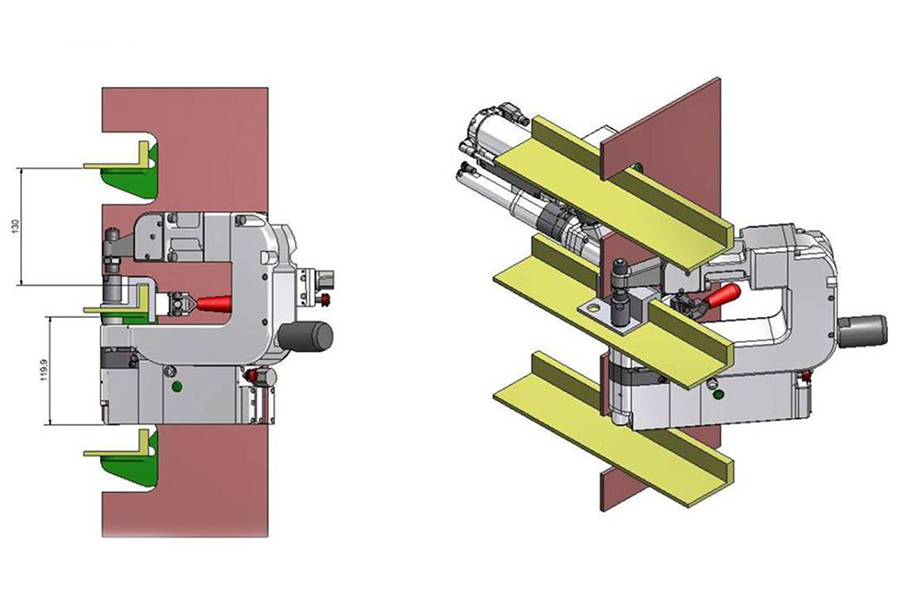

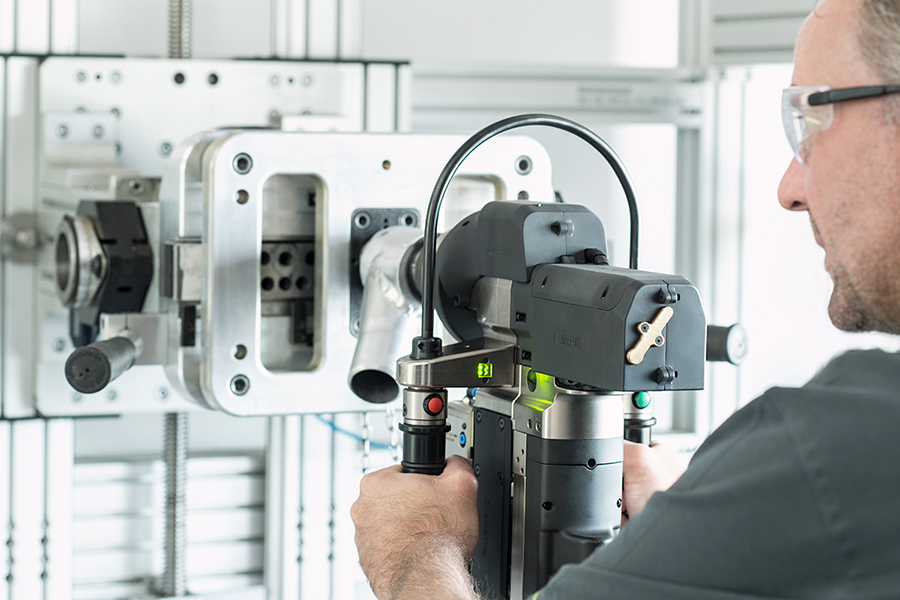

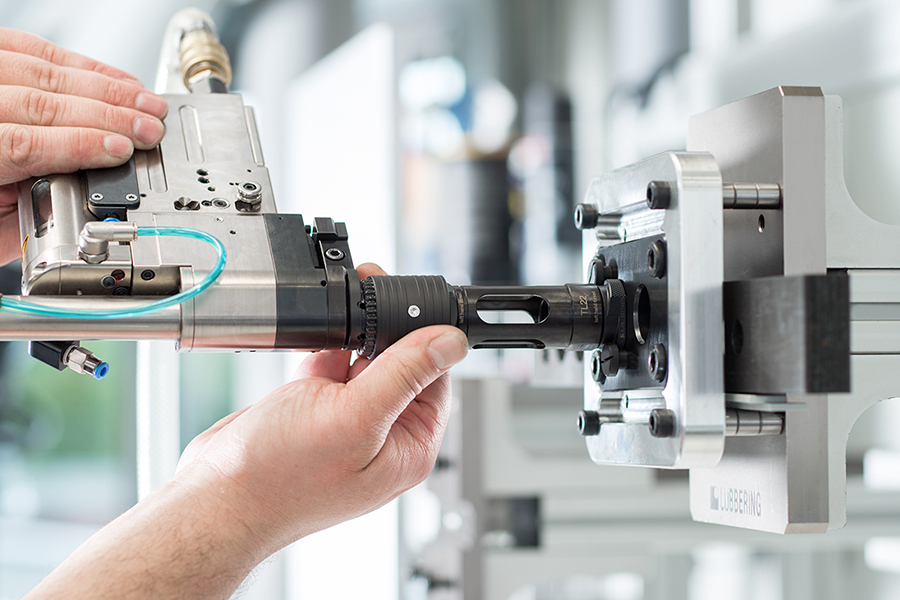

Cockpit

What is drilled?

- The window frames of the cockpit

What is Lübbering's solution?

- L.ADU locking system C-Frame (CF)

- The Frame is called C-Frame because of its form and it is available in different sizes

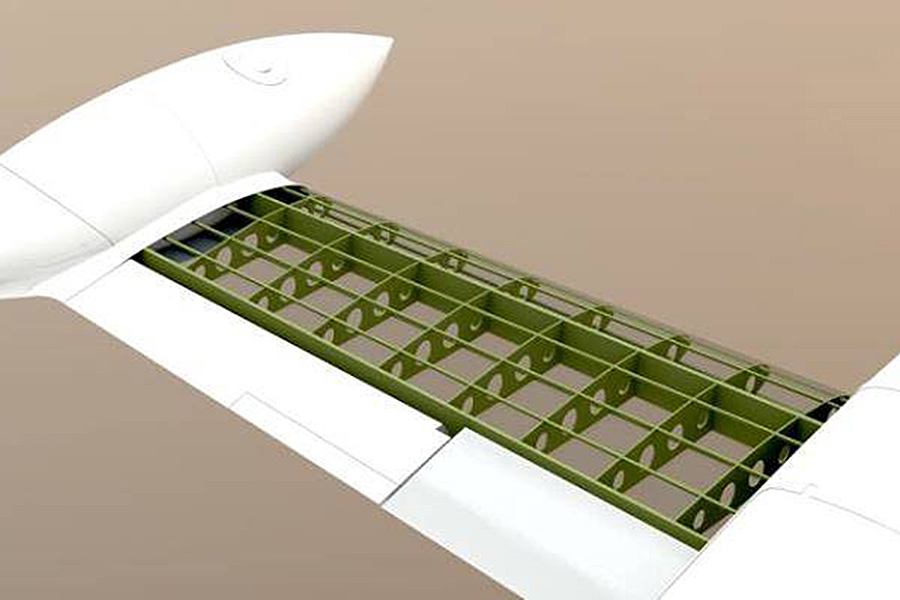

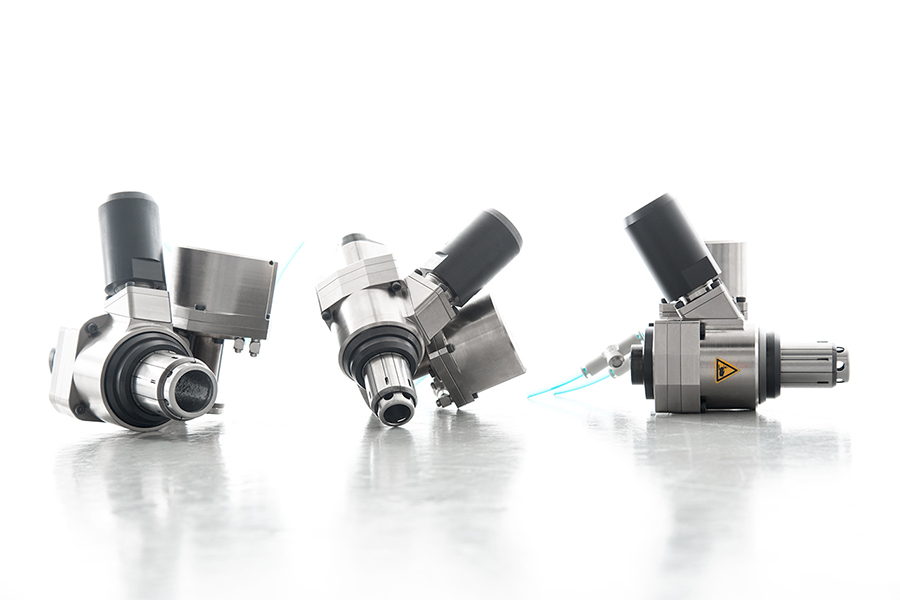

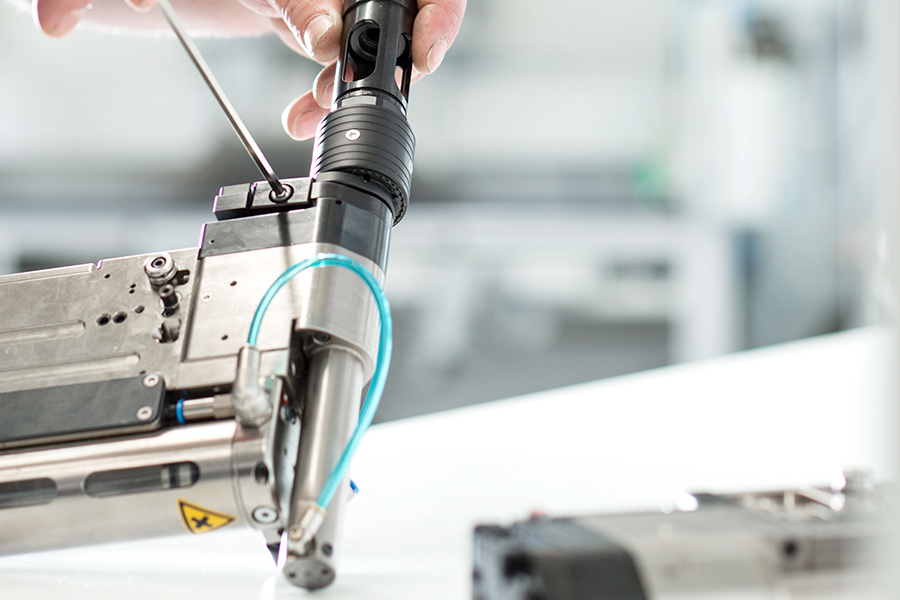

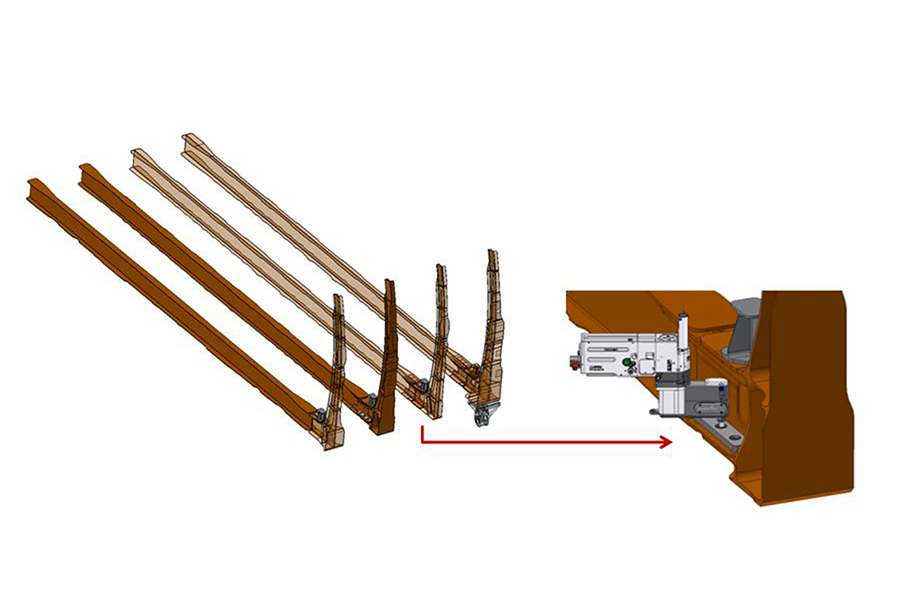

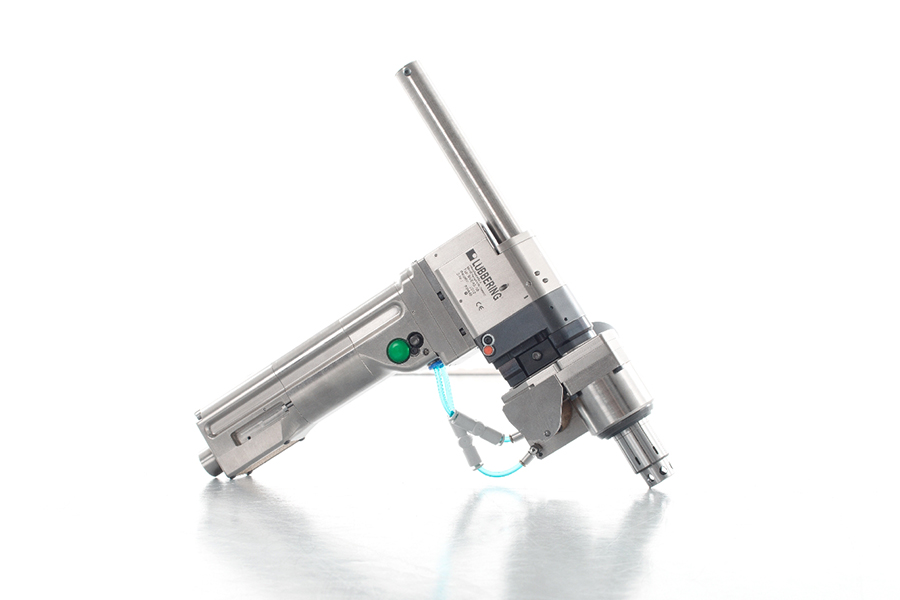

Wing assembly

What is drilled?

- A wing consists of a front spar, a mid spar and a rear spar

- Cleats are used to connect the stringers with the rib. Thus, the wing gets stabilized

- Skin to rib

What are the difficulties?

- Because of the heavily accessible places a hand-operating L.ADU is needed

- Cleats have piloted holes for much easier positioning of the drilling unit

- Skin to rib: critical access – manhole area

What is Lübbering's solution?

- One-shot drilling and countersinking

- With L.ADU pneumatic Concentric Collet (CC) and L.ADU pneumatic Twist Lock (TL) it is easy to drill holes through the front spars, mid spars and rear spars

- With L.ADU pneumatic C-Frame (CF) it is easy to drill holes through the piloted hole of the cleat into the rib

- For the skin to rib application we recommend the L.ADU pneumatic HS 60 (High-Speed) with delta traverse unit and reaction arm

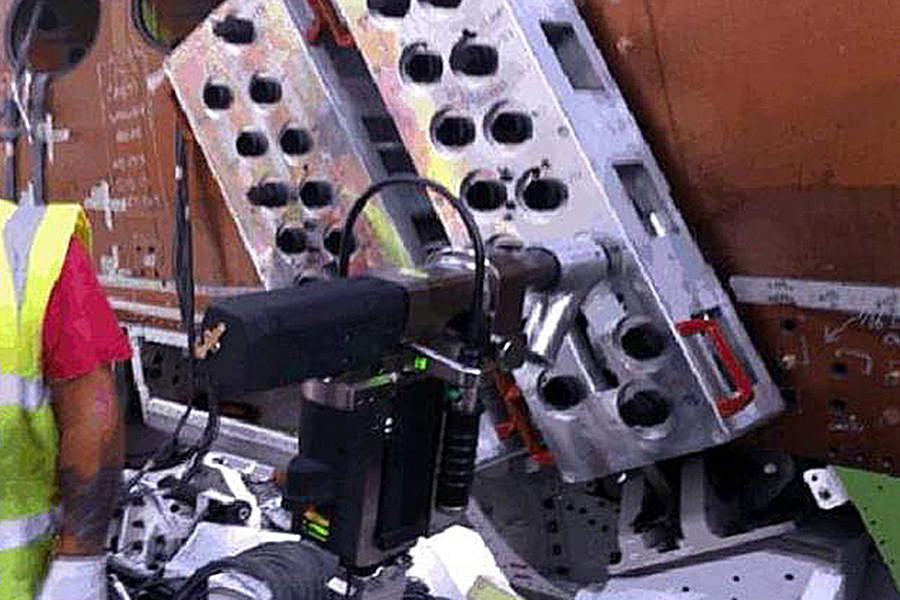

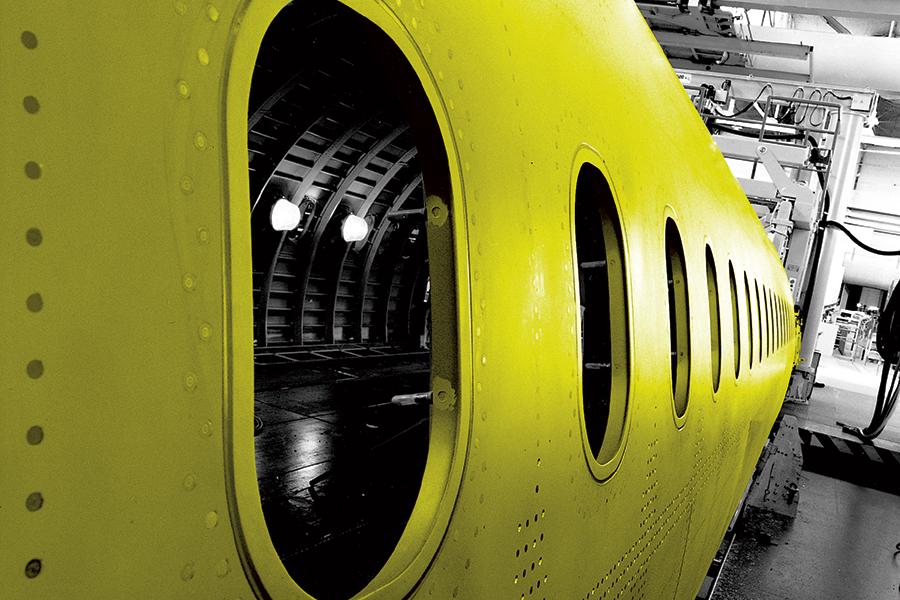

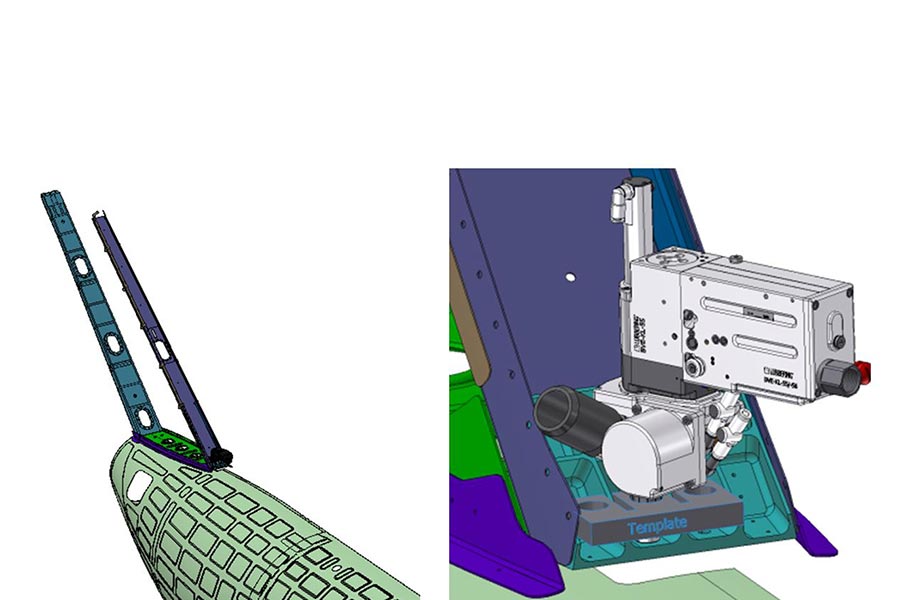

Pre-FAL (section assembly)

What is drilled?

- Assembly of all sections of the fuselage

What is Lübbering's solution?

- L.ADU pneumatic Concentric Collet (CC)

- No gaps between thin material layers (stacks) due to high clamping force

- Nose pieces in full surface contact with component guarantees nearly 100% extraction of chips and dust

- Highly effective in dust / chip extraction and countersinking due to full surface contact

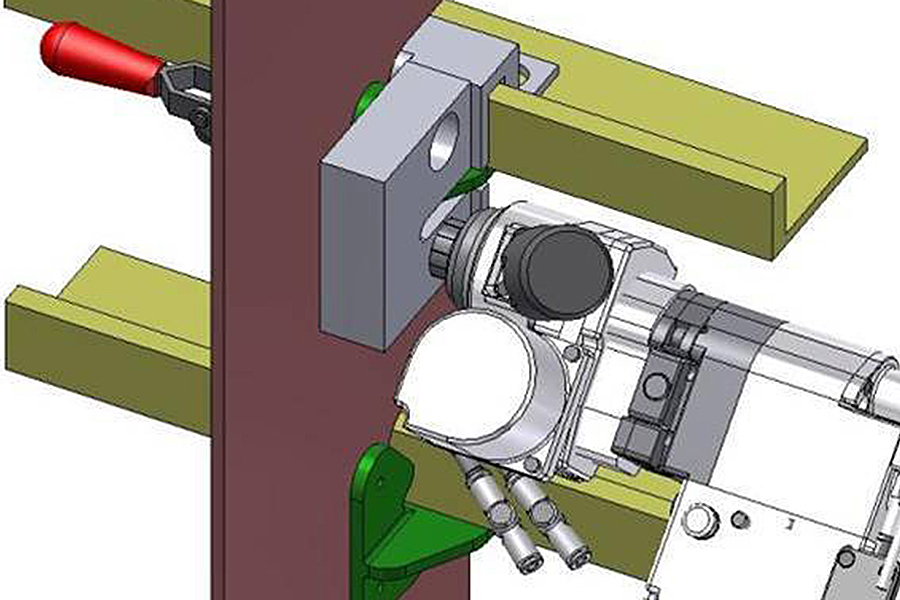

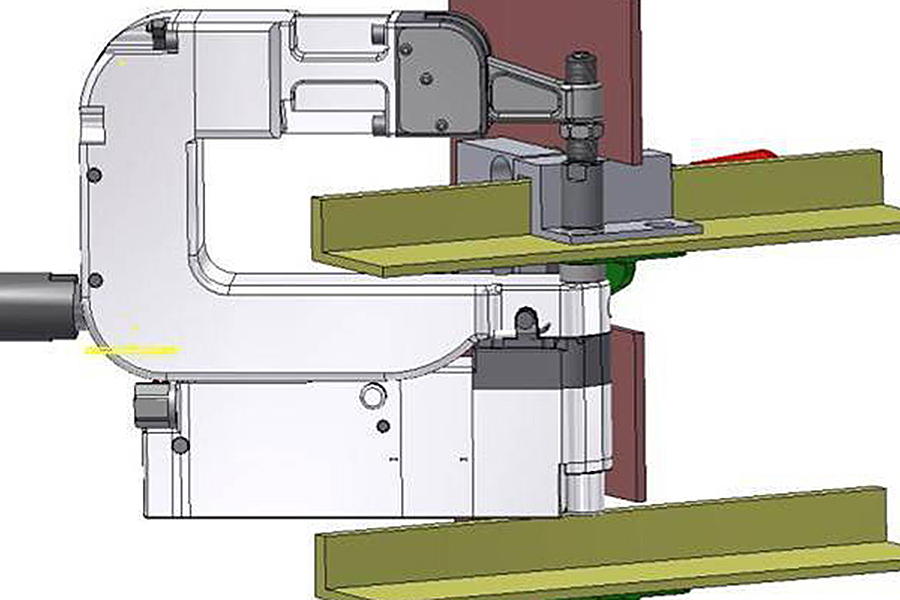

Gear rib assembly

What is drilled?

- For the gear rib assembly, it is necassary to drill holes through the subfloor of the fuselage

- After that the gear rib can be assembled

What is Lübbering's solution?

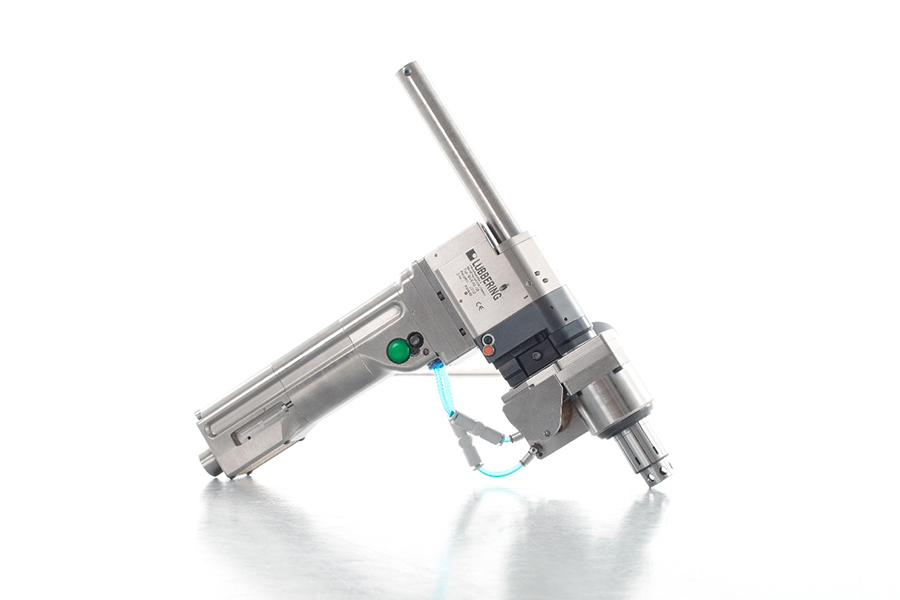

- L.ADU electronic 520 with L.ADU locking system Taperlock (TPL)

- 1st step: 1“ pre-drilling and 1“ ream and countersinking

- 2st step: bolts are sticked into the drilled holes and after that cap nuts are sticked onto it

- The large arm of the fastening tool is needed, because one is not able to hold the cap nut with his own hands and the air plane doesn‘t get damaged

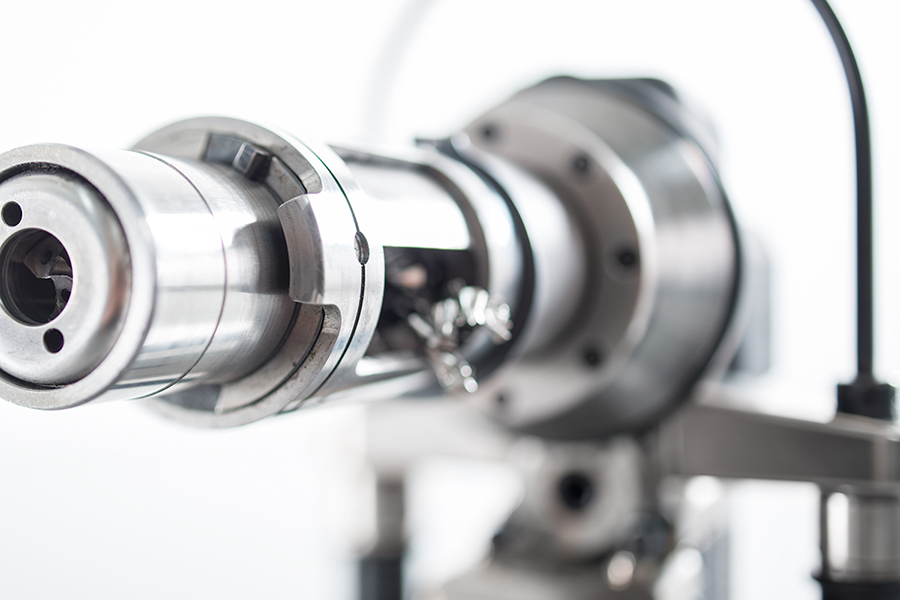

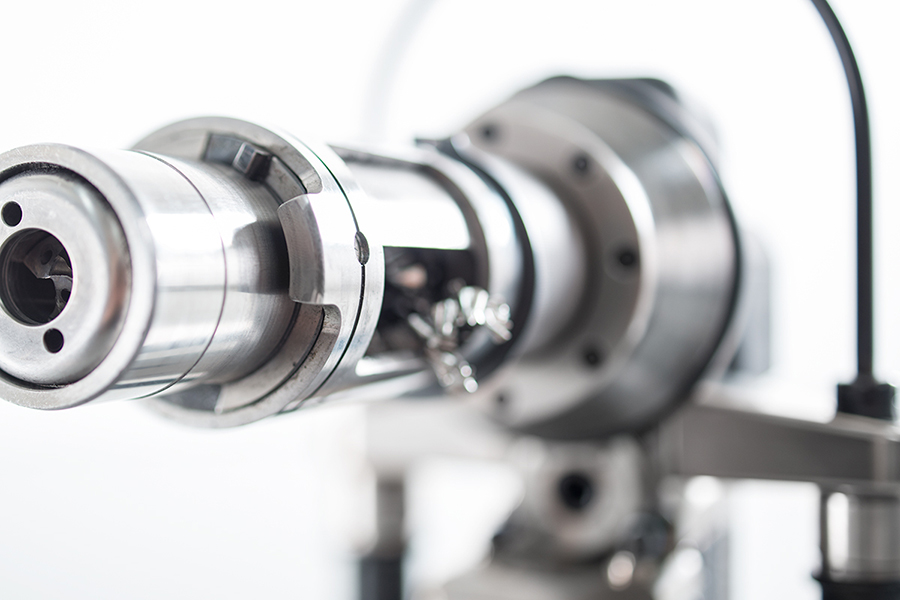

Engine pylon

What is drilled?

- For the engine assembly, it is necassary to drill holes through the junction under the wing

What is Lübbering's solution?

- L.ADU electronic 520 with L.ADU locking system Twist Lock (inline and right-angled version)

- Adaptive Drilling Performance: automatic spindle speed adjustment due to automatic material detection of stacks

- Significant reduction of drilling cycle times through cutter breakthrough sensor

Final wing assembly(FAL)

What is drilled?

- The wings are finally assembled onto the fuselage

- To put in the screw connectors, it is necessary to drill the corresponding holes

What is Lübbering's solution?

- L.ADU pneumatic Taperlock (TPL)

- Designed for larger holes

- Can take a high feed force

- One-shot drilling and countersinking: due to the contact between nose piece and surface, it can countersink

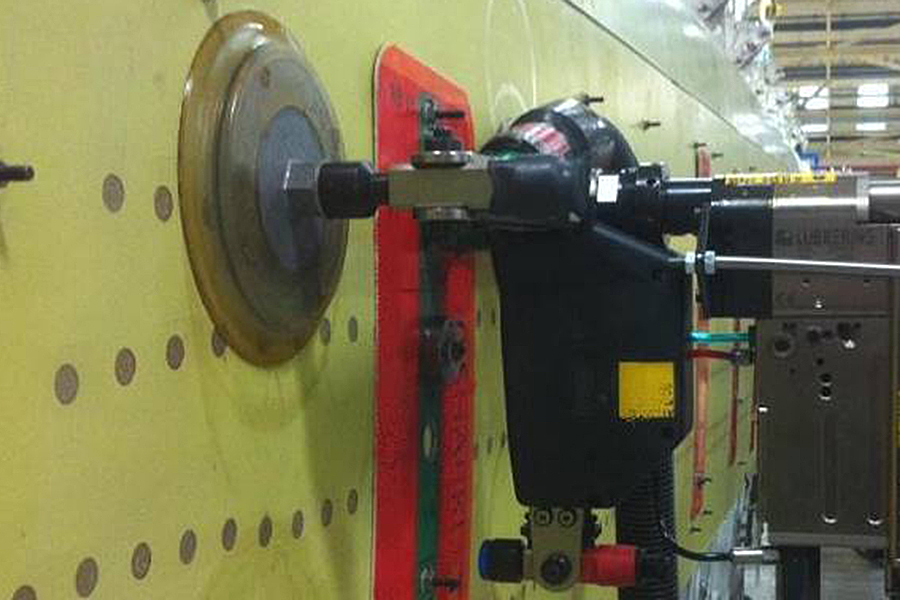

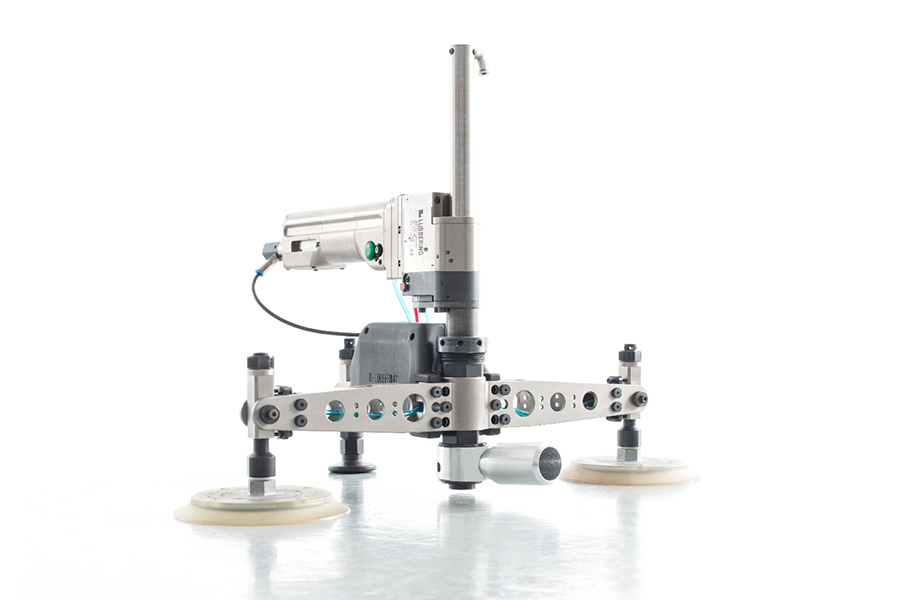

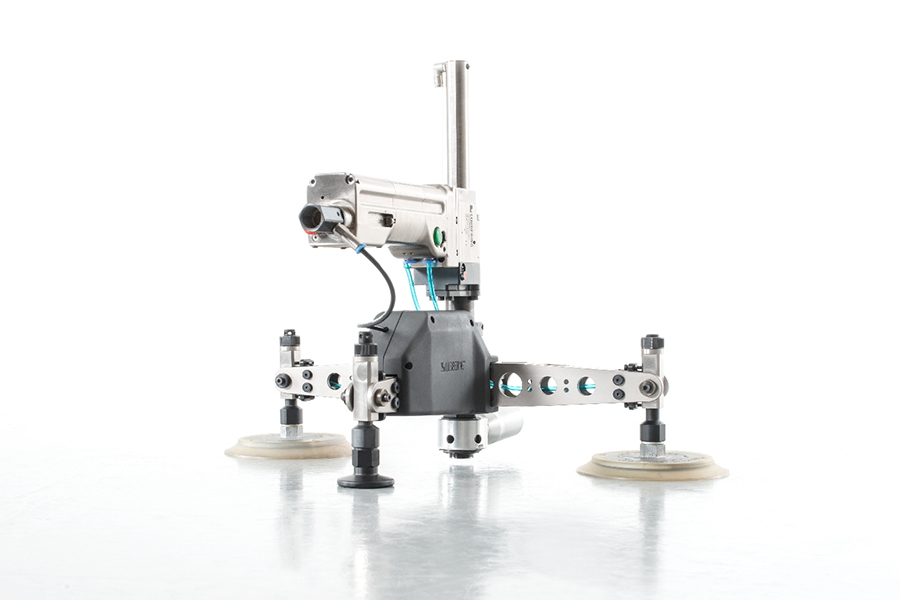

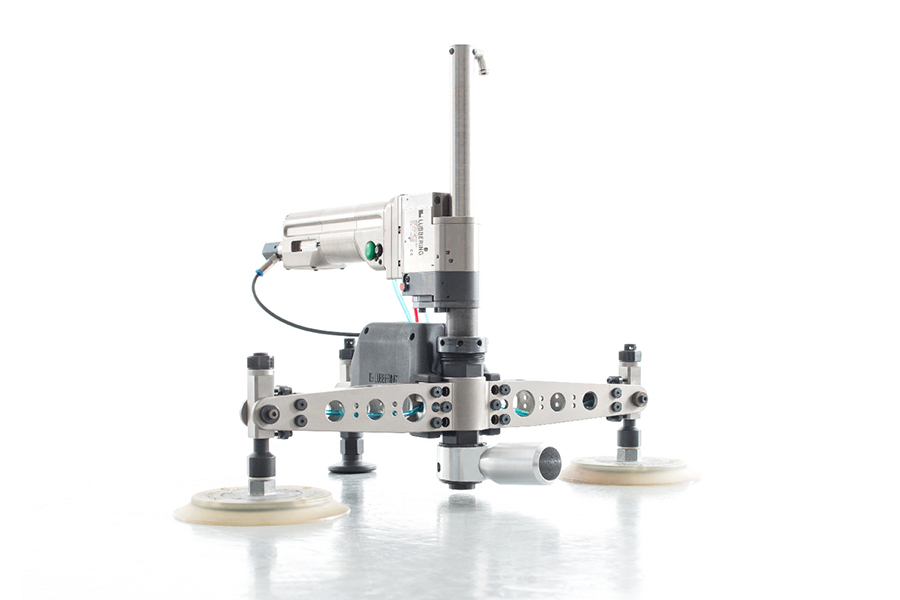

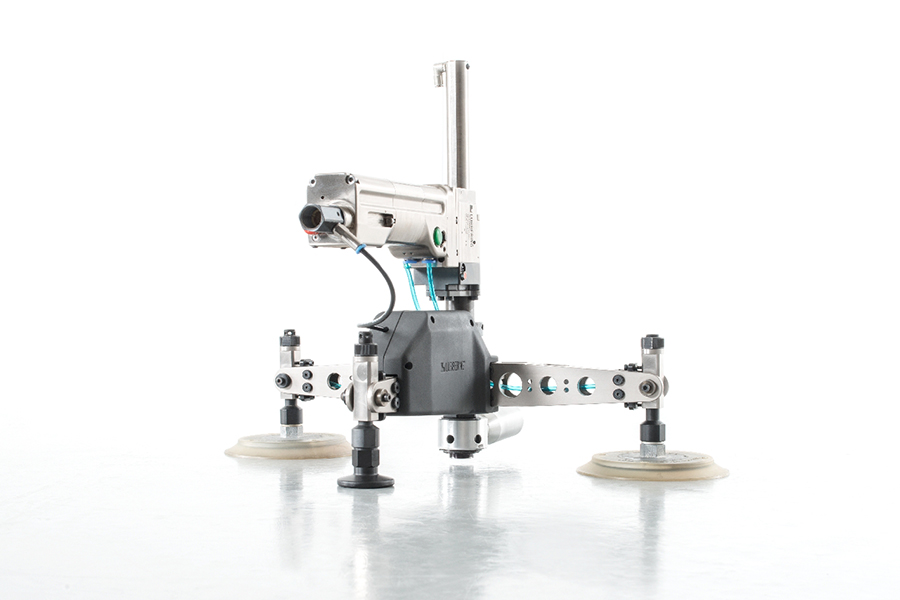

Fuselage outer structure

What is drilled?

- Longitudinal seams

What is Lübbering's solution?

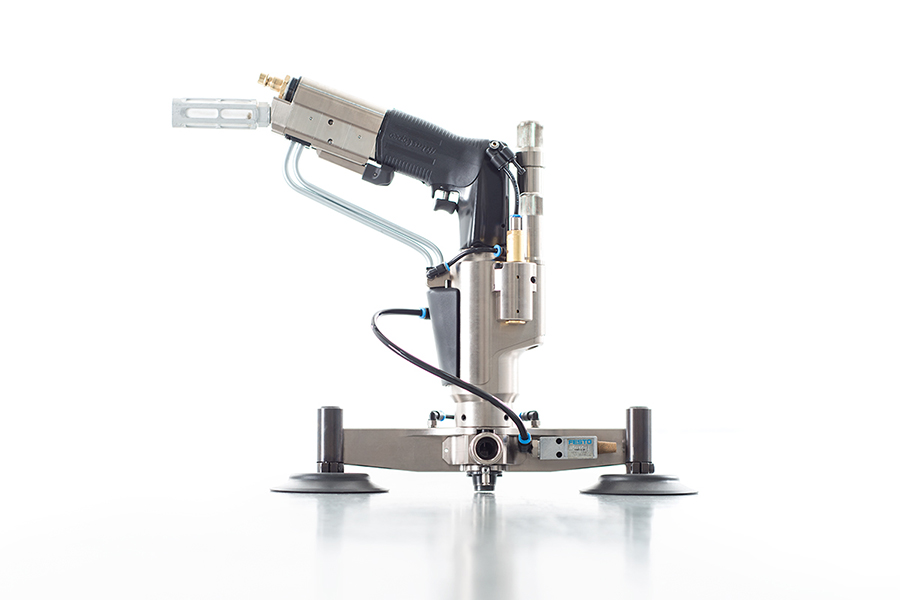

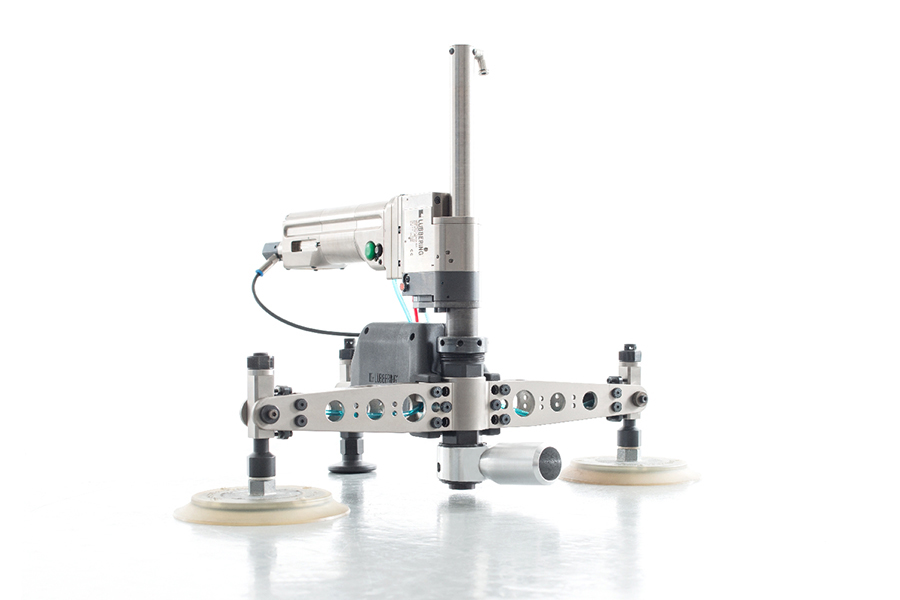

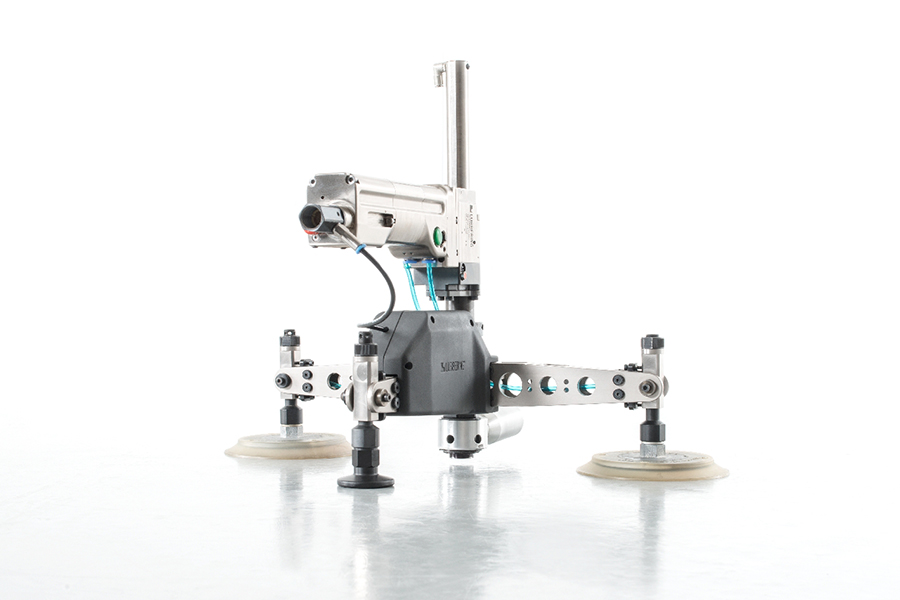

- L.ADU pneumatic Vacuum Traverse (VT) and L.ADU pneumatic HS 60 (High speed)

- Through locking onto the surface via vacuum pads, the drilling machines enable precise drill holes and a secure handling

- Easy positioning through either a pilot cutter, a pilot target or a cheap and simple strip template

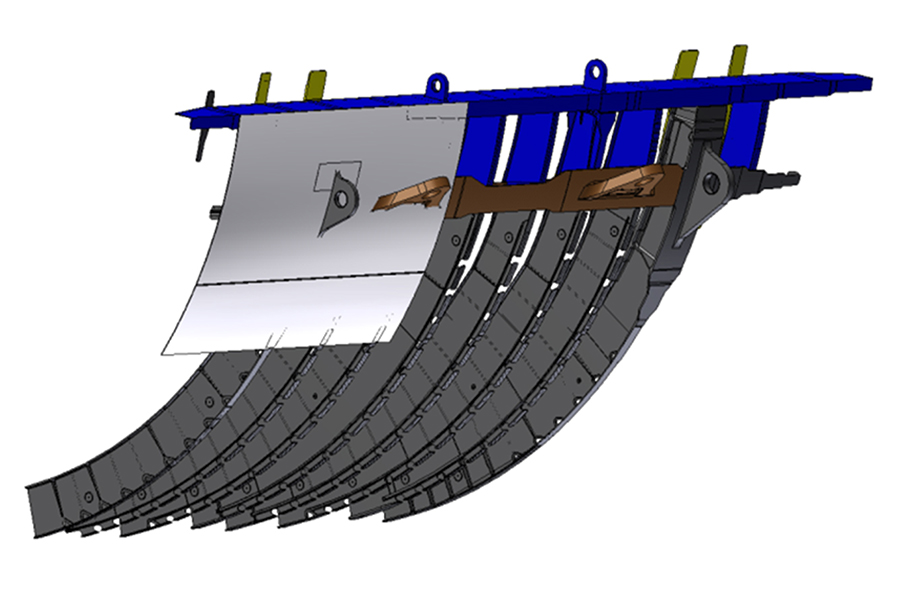

Fuselage inner structure

What is drilled?

- Pre-shell assembly

- Spar joints assembly

- Floor grid assembly

- Seat rails assembly

What are the difficulties?

- A high clamping force is necessary to drill precise holes through the shell

- A very tight access to the floor grid

- A lot of individual components and series

What is Lübbering's solution?

- Pre-shell assembly: L.ADU pneumatic Concentric Collet (type 55) ensures a high clamping force for all drilling operations

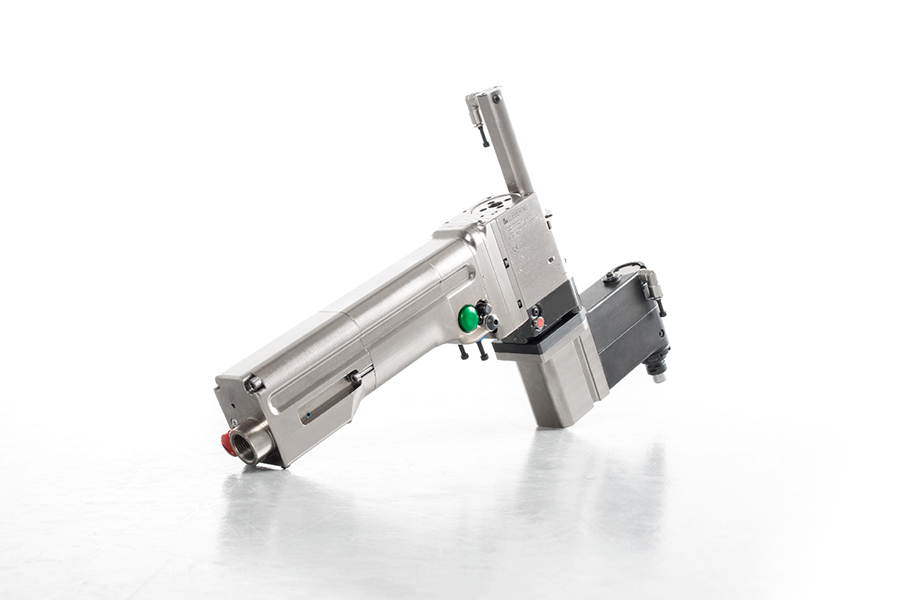

- Floor grid: L.ADU pneumatic Geared Offset (GO) for very tight accesses

Door surrounding

What is drilled?

What is Lübbering's solution?

- L.ADU pneumatic Vacuum Traverse (VT)

- Locks onto the surface via vacuum pads

- Easy positioning through either a pilot cutter, a pilot target or a cheap and simple strip template

Vertical/horizontal tail plane

What is drilled?

- Drilling holes through the rear fuselage to assemble the Horizontal Tail Plane (HTP) and Vertical Tail Plane (VTP)

What is Lübbering's solution?

- L.ADU pneumatic Concentric Collet (CC)

- No gaps between thin material layers (stacks) due to high clamping force

- Nose pieces in full surface contact with component guarantees nearly 100% extraction of chips and dust

- Highly effective in dust / chip extraction and countersinking due to full surface contact