L.ADU electronic 255/256

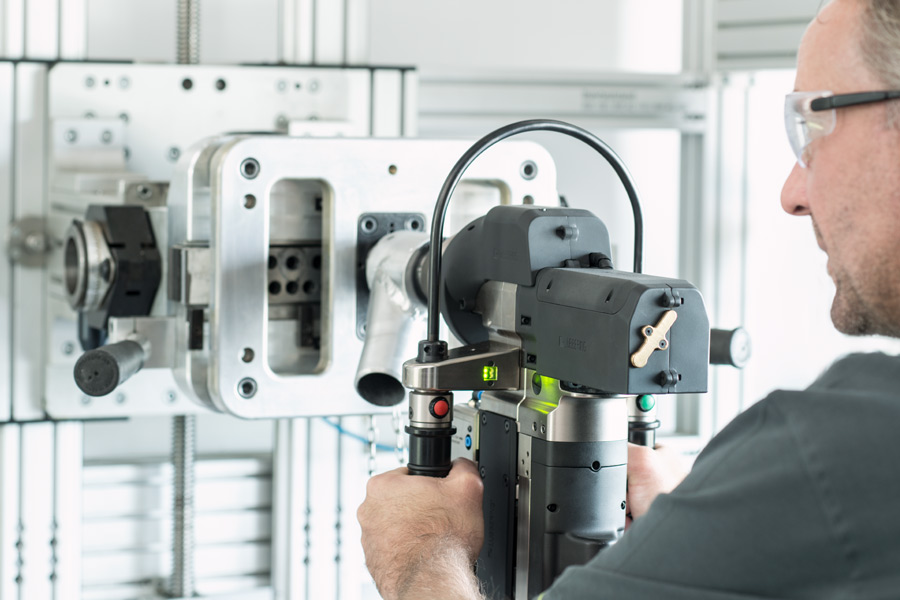

The smartest way of drilling is Born: L.ADU electronic 255/256.

L.ADU combines all the advantages of a pneumatic drilling unit with the efficiency, solidity and programmability of an electronic one. The motor, which is maintenance-free, reduces energy consumption by up to 90% in comparison with a pneumatic unit.

Every material stack can be drilled with L.ADU electronic 255/256 at an optimum cutting speed. Functions like identifying different materials and penetrating through the material stack help to improve the quality and at the same time serve to reduce process times.

L.ADU electronic 255/256 can be integrated into the module system of L.ADU pneumatic and can also make use of the complete range of spindles, tool interfaces, interlocking systems and options. Therefore, pneumatic units can be replaced by L.ADU electronic without changing existing infrastructure or already qualified drilling processes in the production flow. Established maintenance processes and spare part inventory for our feed gears can be continued to use. For this, both L.ADU electronic and L.ADU pneumatic can efficiently be used in a parallel way.

- Very short process times through programmable speeds

- Economical by saving up to 90% energy

- Ergonomic design ensures easy handling

- Environmentally friendly: The amount of cooling lubricant is regulated automatically by the machine due to material detection

- Modular and compatible to L.ADU pneumatic

- Robust and long lasting

- High availability through maintenance-free EC servo drive

- Virtually fail-safe and interchangeable through an integrated control system

- Electronic counter function for maintenance, operating tool time and lifetime of L.ADU

- Fully parameterizable

- Userfriendly through an integrated LCD text display for all important functions

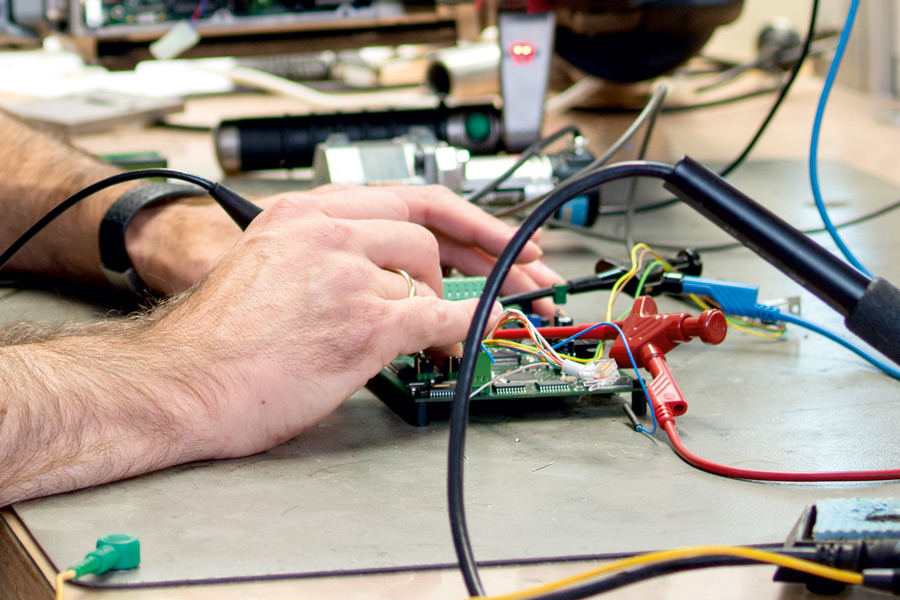

Some call it black box. We call it smart box.

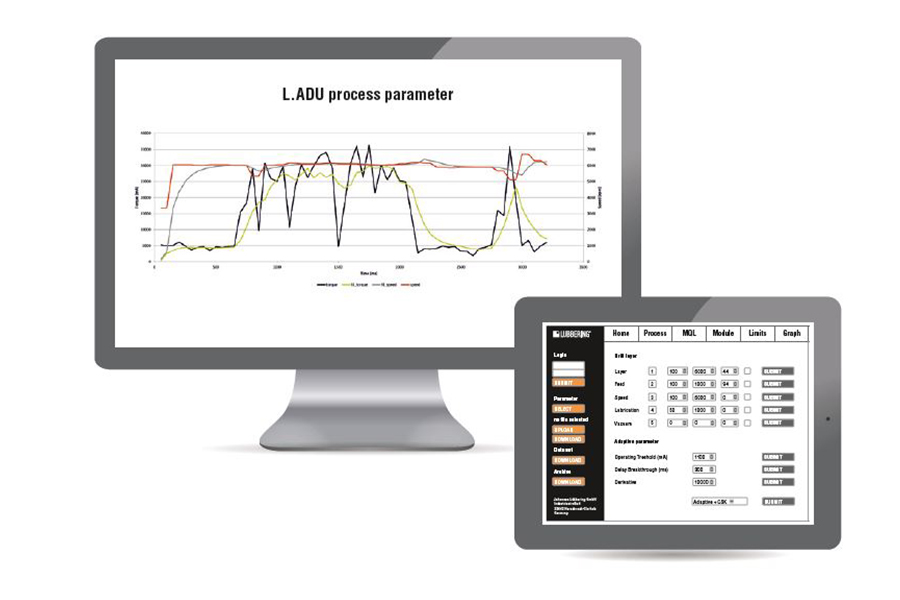

By linking an L.ADU electronic 255/256 to our “smart box“, the system meets all demands which are required on modern production devices in the digital world of today and tomorrow. The current process parameters are transferred online to any L.ADU which is attached and the item is identified via the type of the machine. The System registers every single drilling, and creates a log the drilling time and all relevant parameters. All ctivities and information are stored chronologically in the log file.

All relevant settings remain stored on every L.ADU electronic until the next update via the “smart interface“. This ensures the uninterrupted production flow should there be an error in the network. In this way the current settings are always available for analysis during servicing.

L.ADU smart interface

The intelligent solution for precise drilling in complex materials.

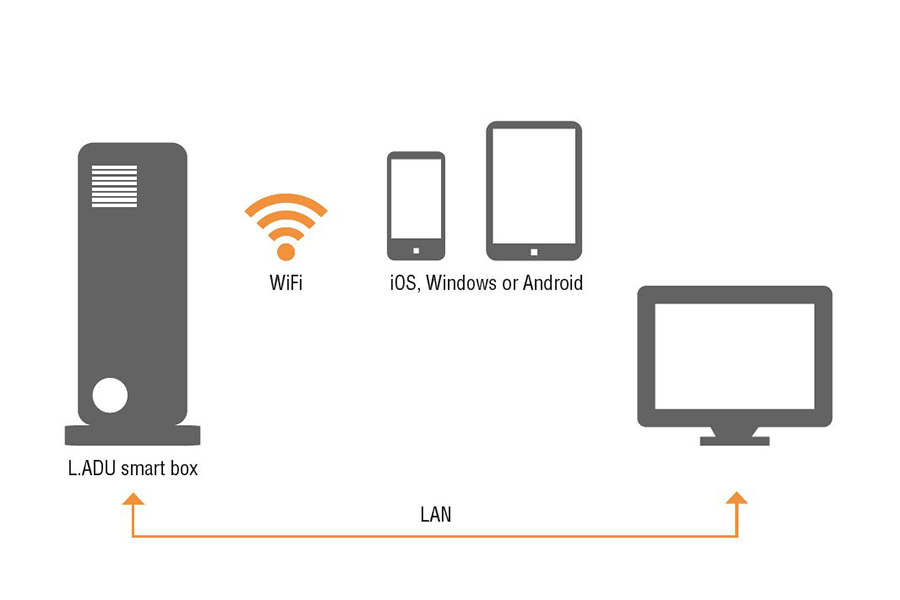

LÜBBERING electronic smart interface serves as gateway between the operator’s computer and the connected L.ADU. The integrated web server enables access to all platform-independent relevant data and parameters. A web browser is required whether on an iOS, Windows or android device. The installation of local software is not necessary.

The system can activate its’ integrated WiFi. So, it allows access by mobile device without any other infrastructure. Different user levels always ensure security. A connection via LAN is also possible, even the access via internet worldwide.

In order to guarantee an internal real time clock of the L.ADU electronic, the machine can also be used when the “smart interface” is offline. A clock and sufficient memory for the data ensure that the information is always stored correctly, without connecting to the network. The data can then be collected later.

Standardized data formats like XML or XLSX are used for the data interchange with the smart interface. These formats can also be managed, modified and evaluated irrespective of the platform. Special software is therefore not needed. This structure allows simple integration into existing IT systems. The server application of the LÜBBERING smart interface is designed to be open, Linux based and is thus really ready for the future. This is essential for today’s tools which have long lifecycles.

- An integrated web server allows access irrespective of the platform

- WiFi or LAN connection with an integrated DHCP server for easy access

- XML parameter files

- Creation of a dataset for every drill

- Automatic creation of an excel file including a design of the drilling process

- Log file for all activities and messages

- The customer does not need local software

- Creation of data diagrams online, in real time

- Maintenance functions for L.ADU

- Update functions for the server and the web interface via remote maintenance

L.ADU electronic 520

One machine for all materials with automatic layer detection.

Extremely challenging and thick hybrid stacks such as CFRP, aluminium and titanium is no problem for L.ADU electronic 520.

During the drilling cycle the machine detects the different material layers and adjust the rotation speed to the material automatically. The integrated thrust sensor also identifies the breakthrough point. All this leads to extremely short cycle times.

- Large holes in sensitive combinations

- Adaptive Drilling Performance: automatic spindle speed adjustment due to automatic material detection of stacks

- Significant reduction of drilling cycle times through cutter breakthrough sensor

- Optimised and constant cutting Speeds through ground spindle

- Time saving by one-shot drilling | reaming and countersinking

- Emergency stop through button

- Overload protection by controlled spindle speed and torque

- Process Information by LC display and signal lights

- Full traceability of process data via Feed Force and Position/Torque diagrams