Learn more about our products of the product category L.SMR service.

Life Cycle Simulation

KNOW TODAY WHAT THE FUTURE WILL HOLD.

The general trend in the automotive industry can be summed up very simply: More functionality in smaller spaces with less weight. The joining technology used in these vehicles must therefore be lighter in order to meet emissions requirements. This has the following effect on assembly technology: Screws and nuts which are already pretightened to their load limits must be capable of being fastened within ever decreasing tolerances. At the same time, installation space is being taken up with more and more components and is so becoming ever smaller.

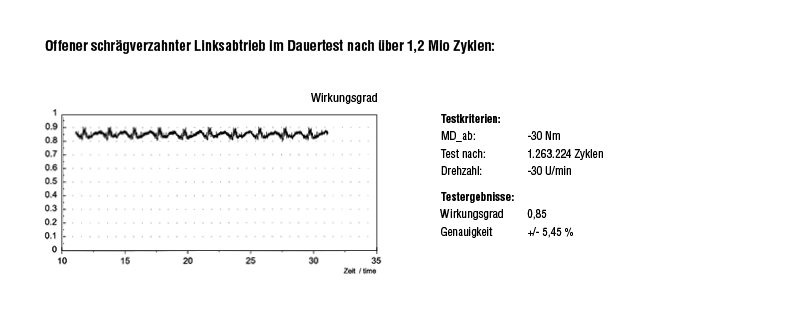

This high-precision fastening is possible with LÜBBERING products. In order to achieve this, we sometimes have to push beyond the physical limits of the materials used. In order to ensure that we provide reliable information about service life and offer our customers calculable availability, we prepare individual service life analyses of our geared offset heads upon request for our customers. Here, torque and efficiency are documented and evaluated cyclically. This is followed by an inspection of the components, and the life cycle simulation is completed with a detailed description and evaluation.

- Reduced risk of unforeseen failure

- Optimisation of the fastening process

- Creation of new areas of application

Your advantages:

RUNNING-IN

EXCEPTIONAL PREPARATION FOR EXCEPTIONAL EFFICIENCY.

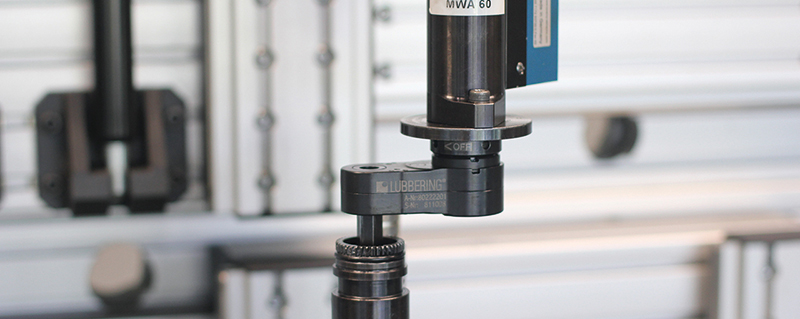

Repeatable quality, consistent performance and total precision – these are the essential requirements for any fastening tool. The running-in of geared offset heads on our specifically designed test rig, satisfies precisely these requirements. Before final acceptance, the geared offset head is subjected to 3,000 simulated fastening cycles at the maximum permissible torque. The running-in certificate issued at the end of this test documents present efficiency and serves as the basis for calibrating the entire tool. This unique LÜBBERING service thus enables even better interplay between the tool and the drive machine and delivers consistent quality throughout the entire product life cycle of the geared offset head.

Your advantages

- Constant efficiency

- Individual running-in certificate

- Traceability via serial number

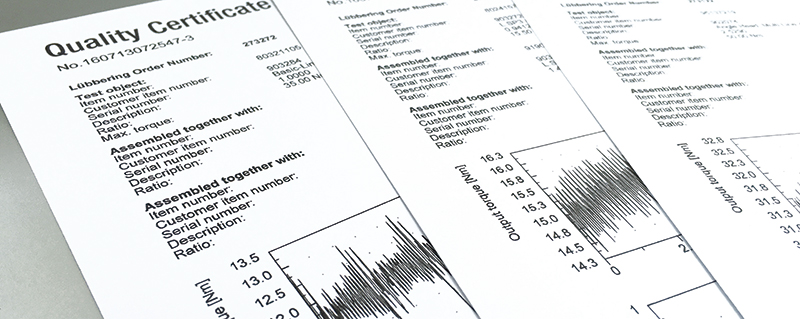

Depending on the size and construction form (open or closed) up to 3,000 fastening cycles are carried out at the maximum permissible or practice relevant torque. After reaching a stable efficiency, the running- in process is completed. The increase in efficiency within the running-in can be up to 10%. At the end of the running-in process, the LÜBBERING quality certificate is issued. The geared offset head or the angle head is tested at the same torque over a specific period of time. As a result the efficiency and the precision are determined. The quality certificate documents all important parameters which are necessary for the later calibration of the entire fastening tool.

Especially to note in this example

- System-ID and serial number: Classification of a geared offset head or an angle head

- Efficiency: 70%

- Precision: +/- 4,23% (Precision of the geared offset head according to the efficiency)

- Transmission ratio: 1.4375

TRIMMING

PEOPLE SAY “YOU CAN’T BEAT OPTIMAL”. WELL, WE CAN.

Trimmed open geared offset heads enable absolute precision in torques on threaded pipe or hose unions in the smallest spaces. Because of their shape and the open output gearwheel, which is what makes this fastening technique possible in the first place, the precision values achievable with open geared offset heads are lower than those of their closed counterparts. In order to be able to perform precise, repeatable fastening operations in these cases, LÜBBERING offers trimming of the geared offset heads as well as running-in. With this process, LÜBBERING is able to optimise open geared offset heads for your individual application, and trim the torque range which is needed to the highest possible degree of precision. Optimising open geared offset heads by trimming is always combined with the running-in.

- Maximum precision for open geared offset heads

- Consistent fastening quality

- Individual quality certificate

Your advantages:

MACHINE CAPABILITY ANALYSIS

A LONG PHRASE BUT A SHORT PROCESS AND EXCELLENT RELIABILITY.

A comprehensive consideration of a fastening process must not only include a test of the individual components but also an analysis of the interplay between them. We are able to analyse the machine capability of fastening systems in different variations. In this statistical procedure, our experts analyse the tolerance consumption and tolerance situation of the fastening system. By the determination of the machine capability indicator (Cm, Cmk) you are able to decide whether the fastening system is suitable for your particular application.

Your advantages:

- Test certificate with measurement results

- Free choice of drive technology

- Test torques from 2 – 1,000 Nm

- Consistent quality