back to overview

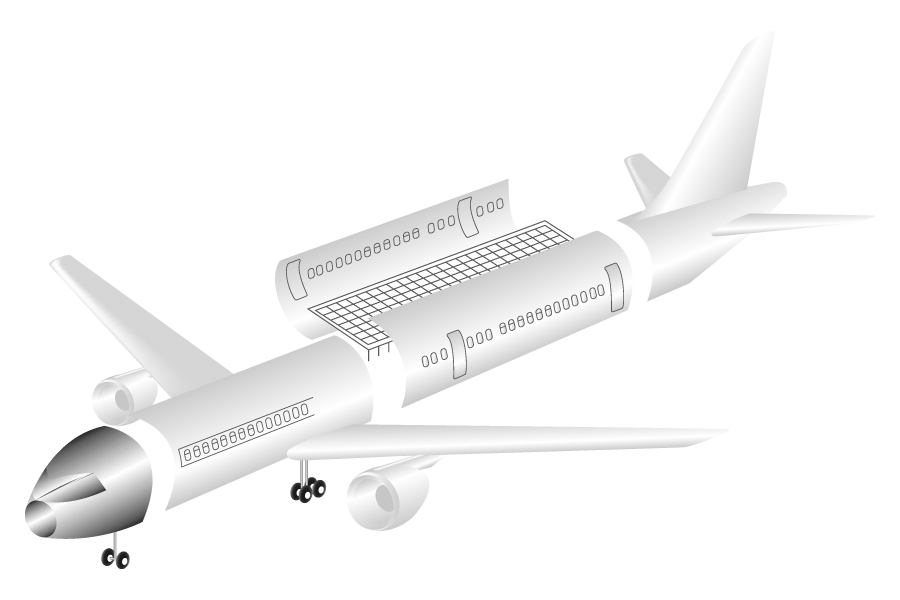

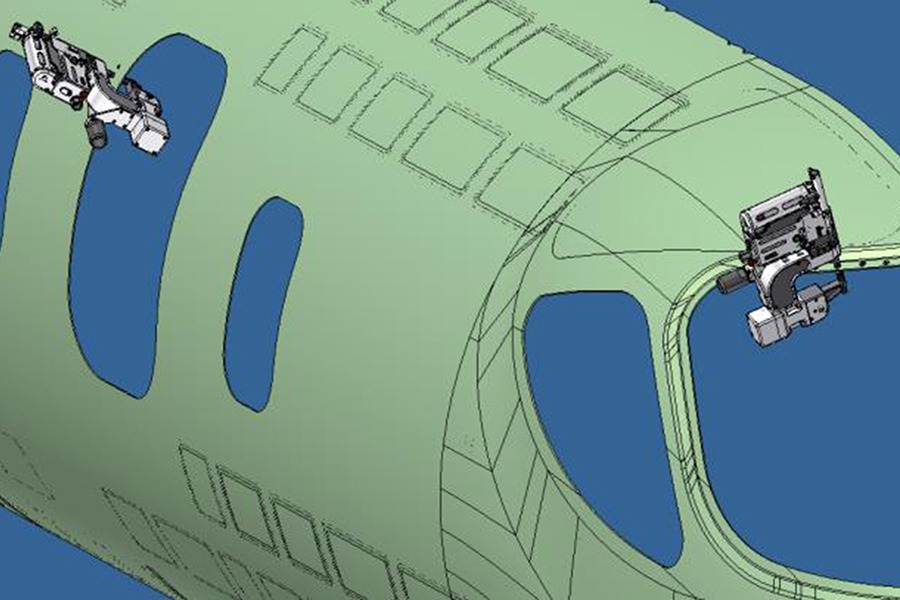

Cockpit

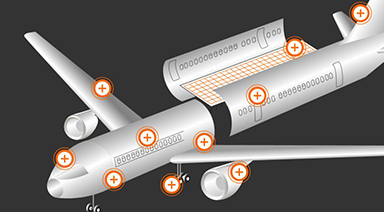

What is drilled?

- The window frames of the cockpit

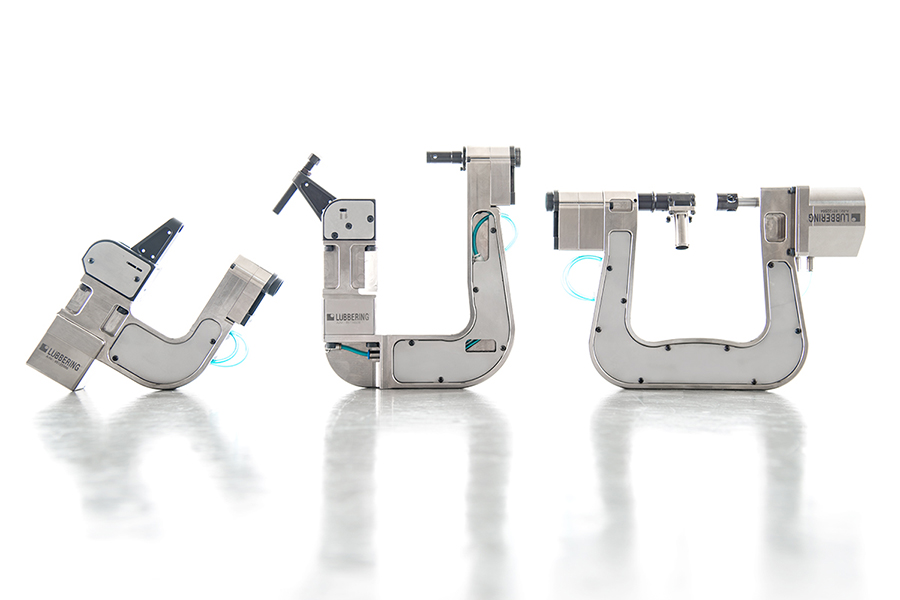

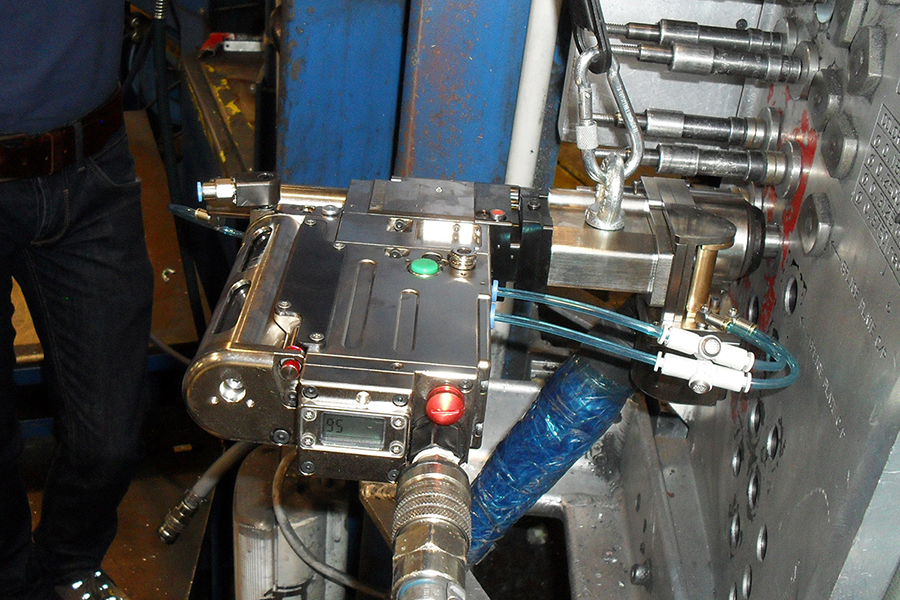

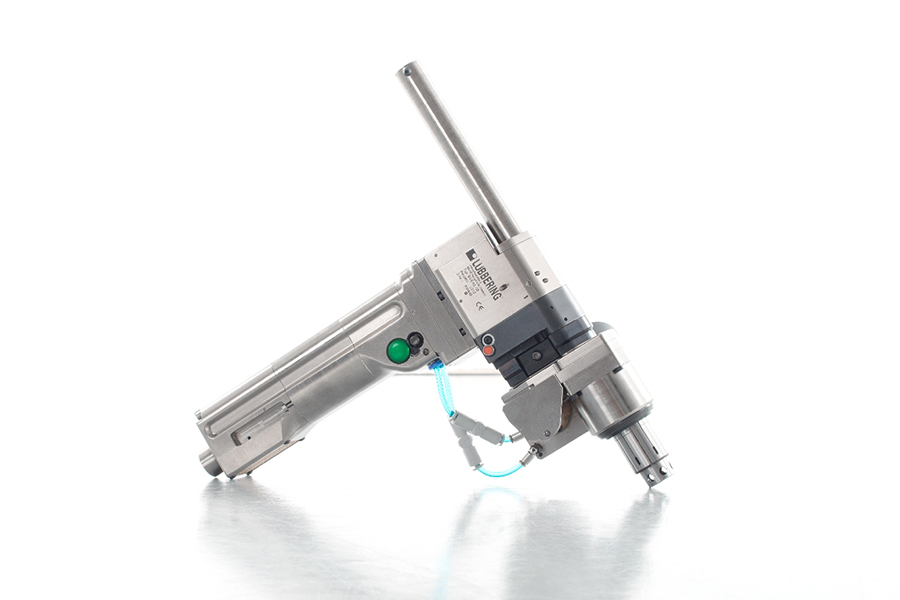

What is Lübbering's solution?

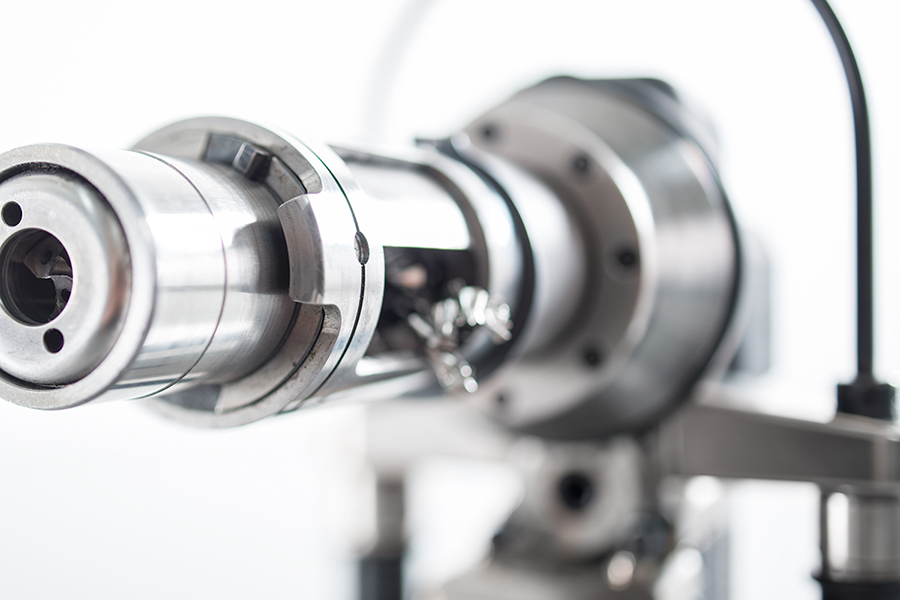

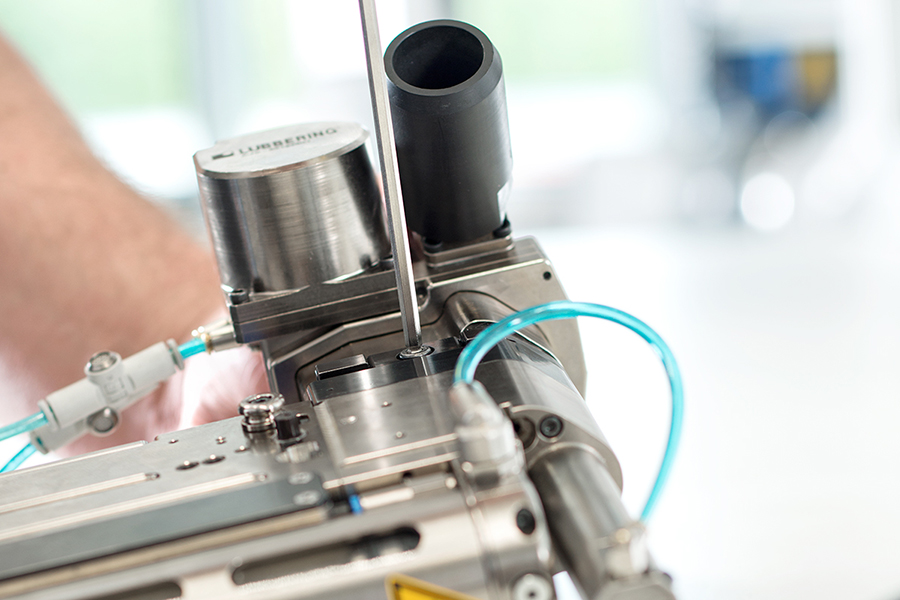

- L.ADU locking system C-Frame (CF)

- The Frame is called C-Frame because of its form and it is available in different sizes

back to overview

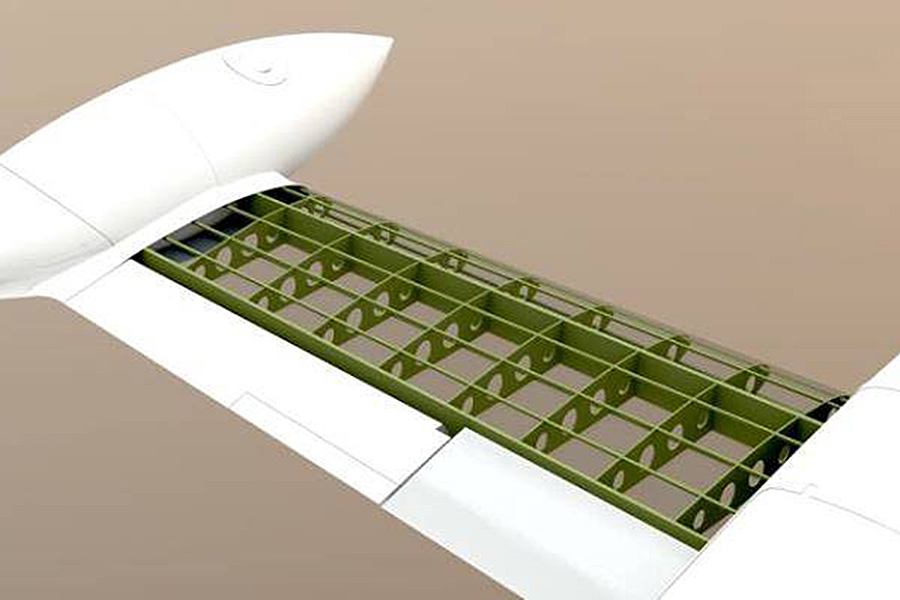

Wing assembly

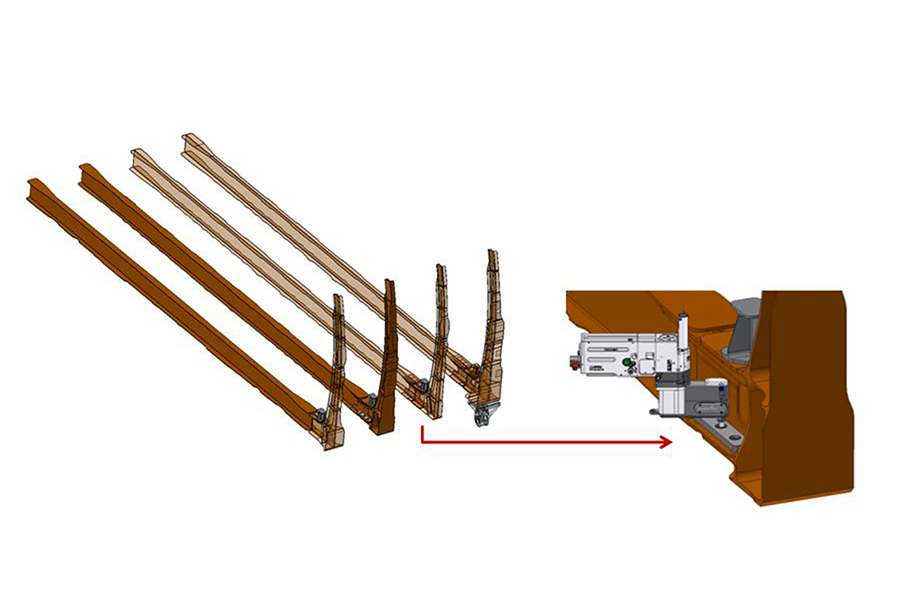

What is drilled?

- A wing consists of a front spar, a mid spar and a rear spar

- Cleats are used to connect the stringers with the rib. Thus, the wing gets stabilized

- Skin to rib

What are the difficulties?

- Because of the heavily accessible places a hand-operating L.ADU is needed

- Cleats have piloted holes for much easier positioning of the drilling unit

- Skin to rib: critical access – manhole area

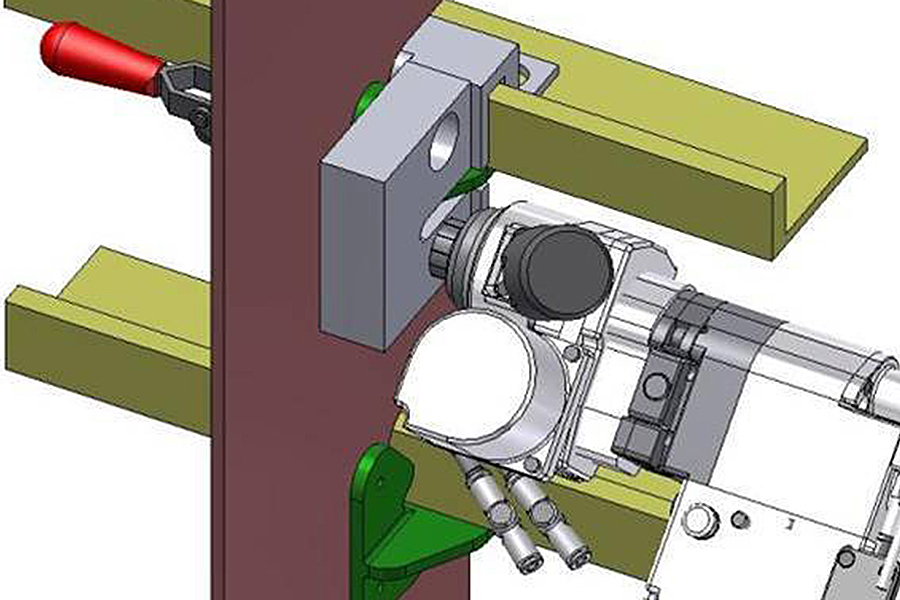

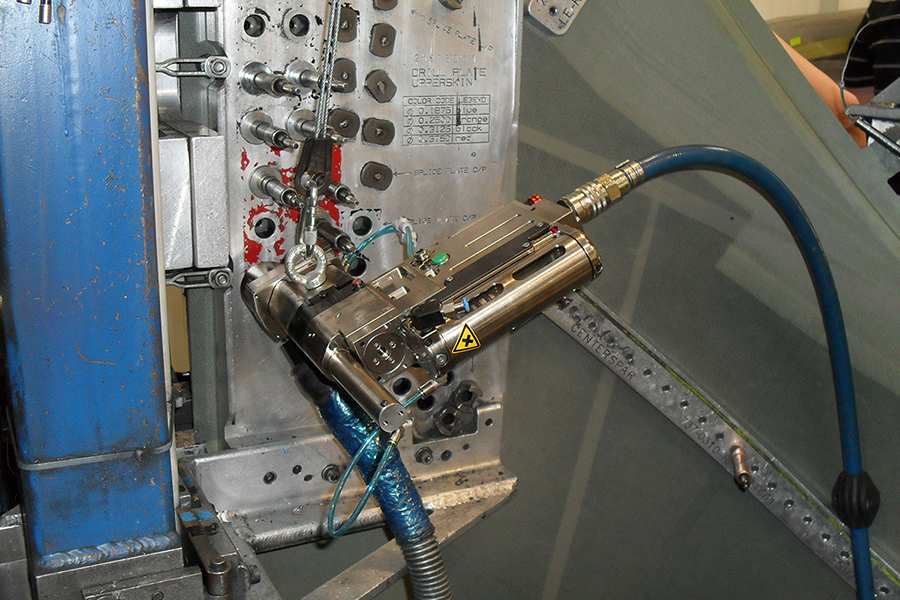

What is Lübbering's solution?

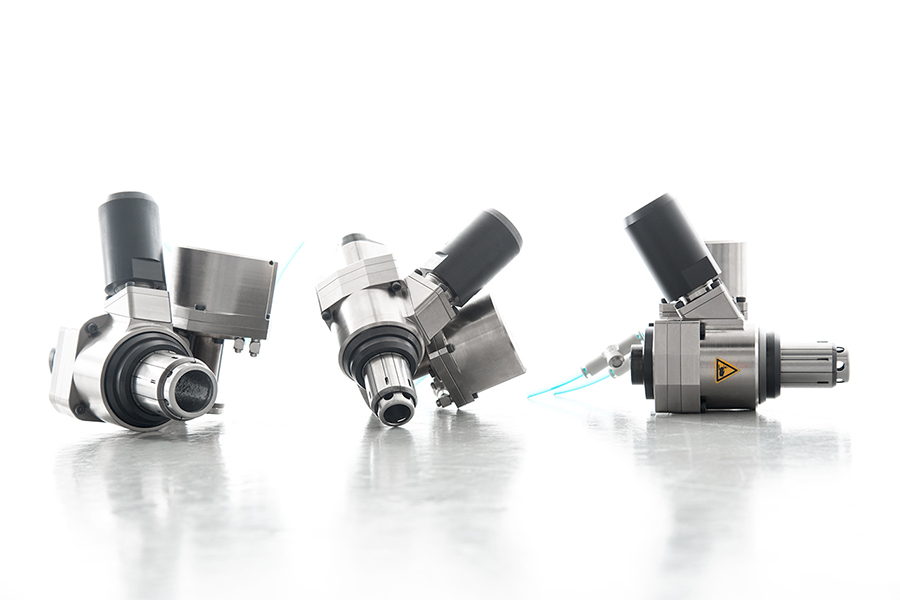

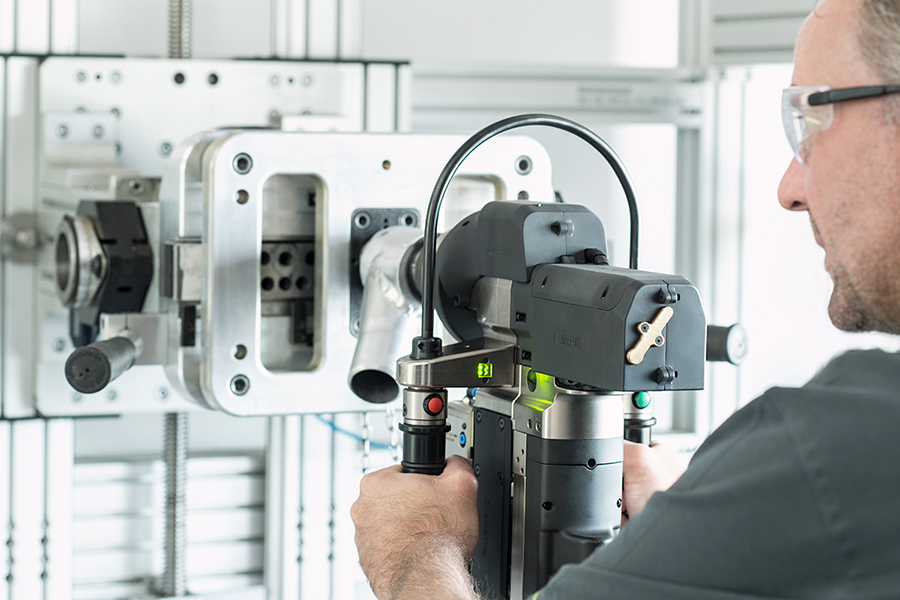

- One-shot drilling and countersinking

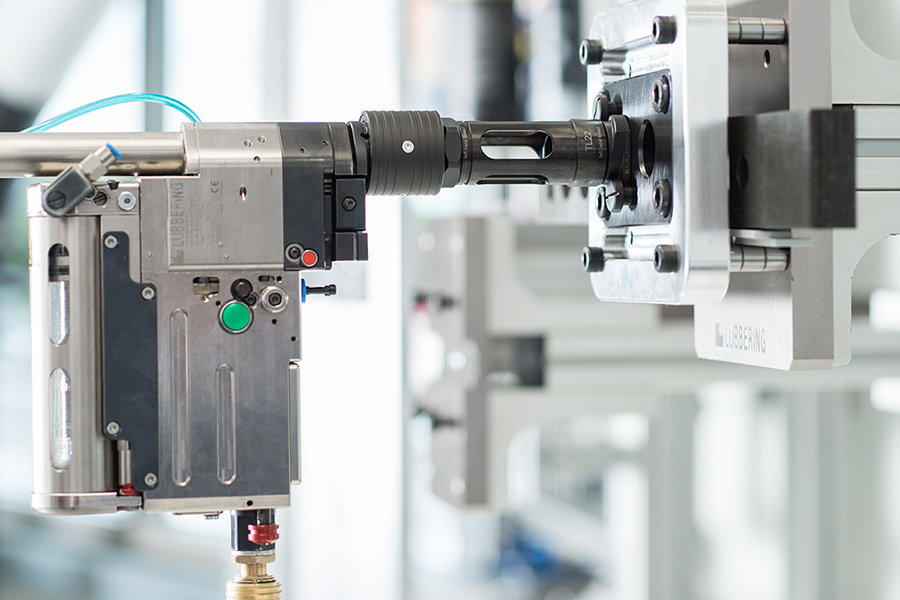

- With L.ADU pneumatic Concentric Collet (CC) and L.ADU pneumatic Twist Lock (TL) it is easy to drill holes through the front spars, mid spars and rear spars

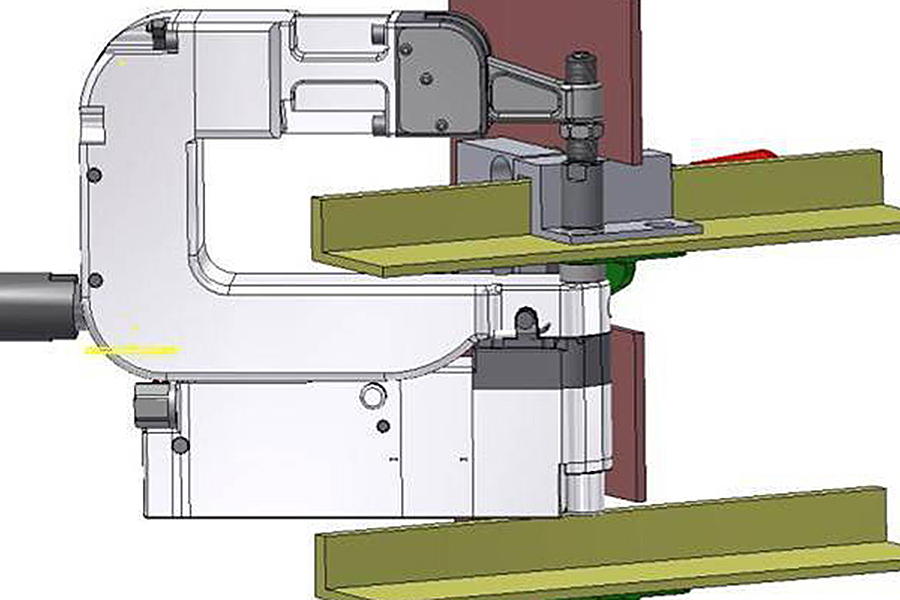

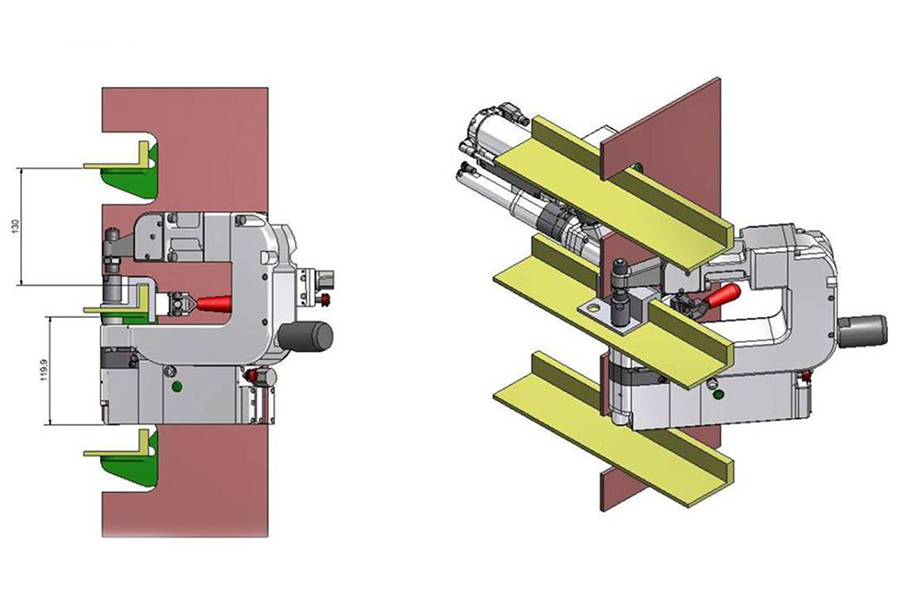

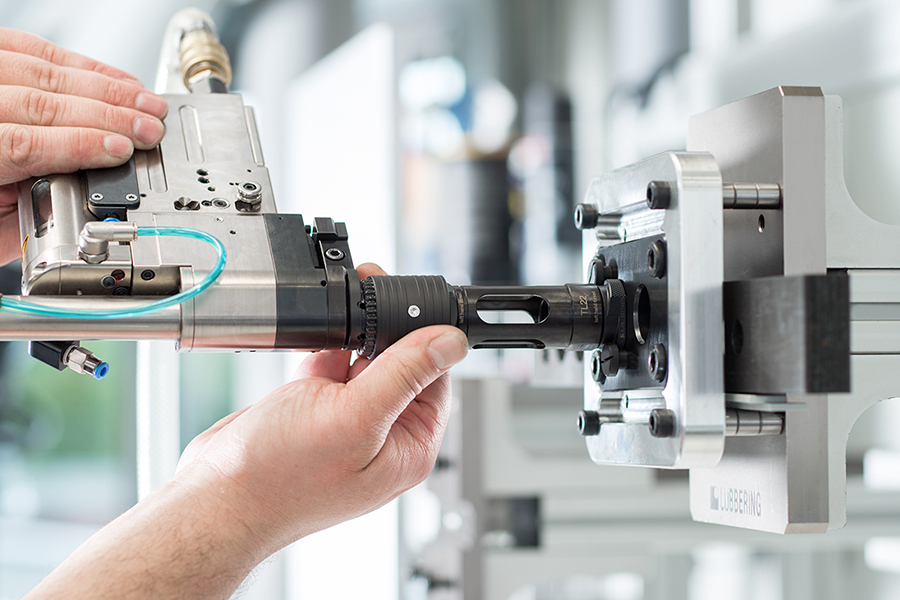

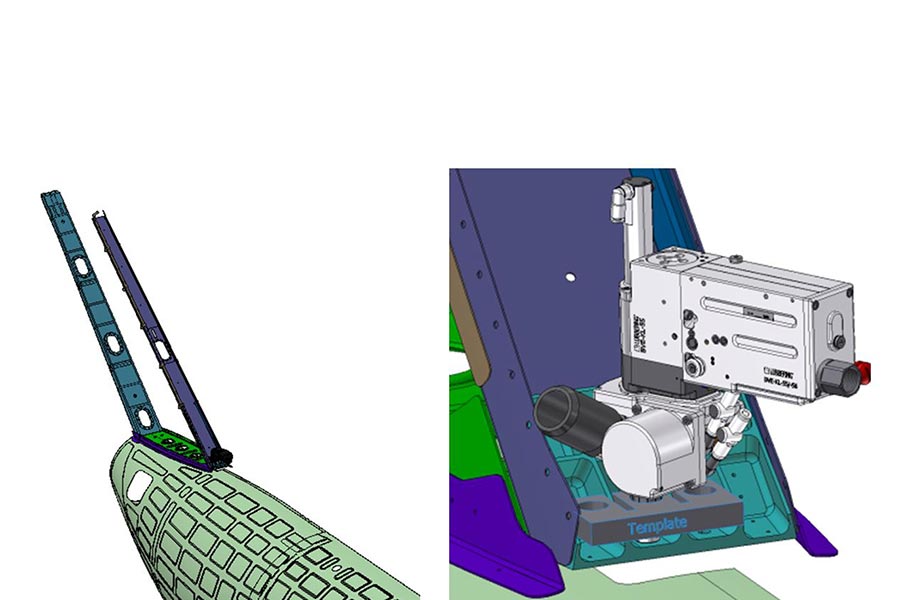

- With L.ADU pneumatic C-Frame (CF) it is easy to drill holes through the piloted hole of the cleat into the rib

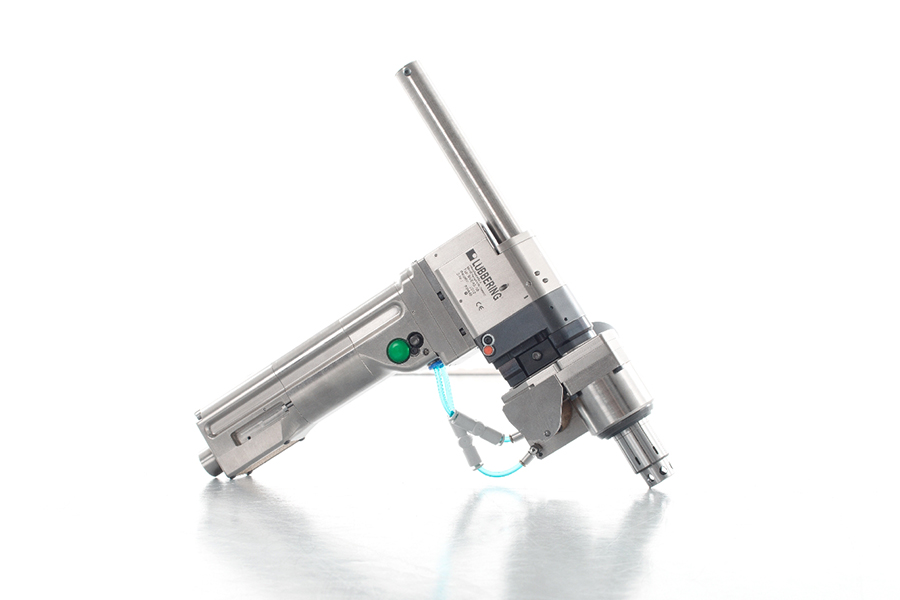

- For the skin to rib application we recommend the L.ADU pneumatic HS 60 (High-Speed) with delta traverse unit and reaction arm

back to overview

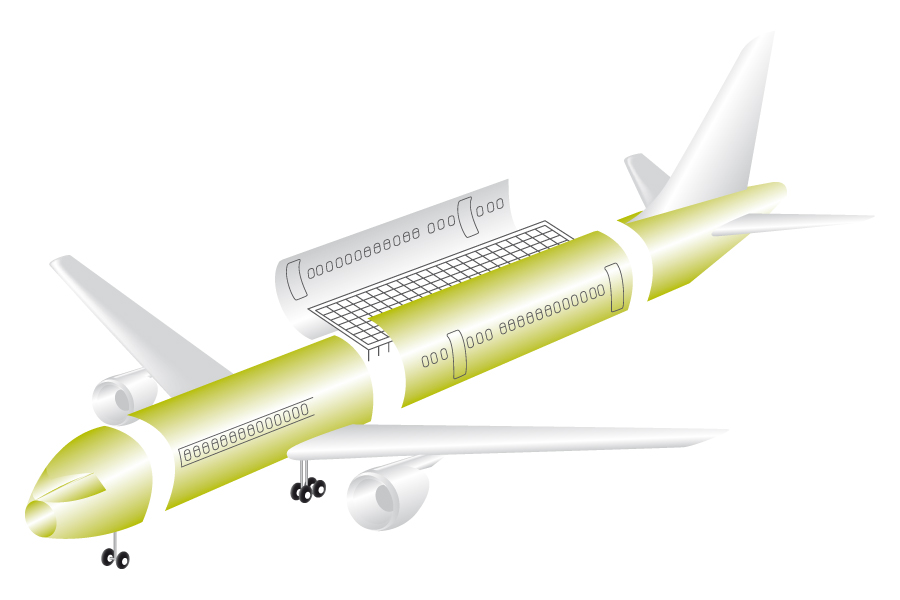

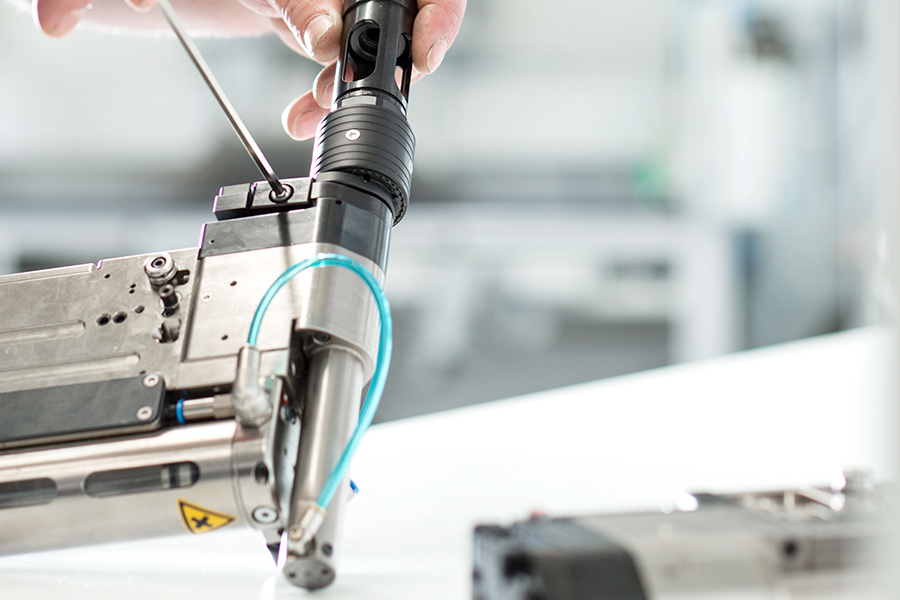

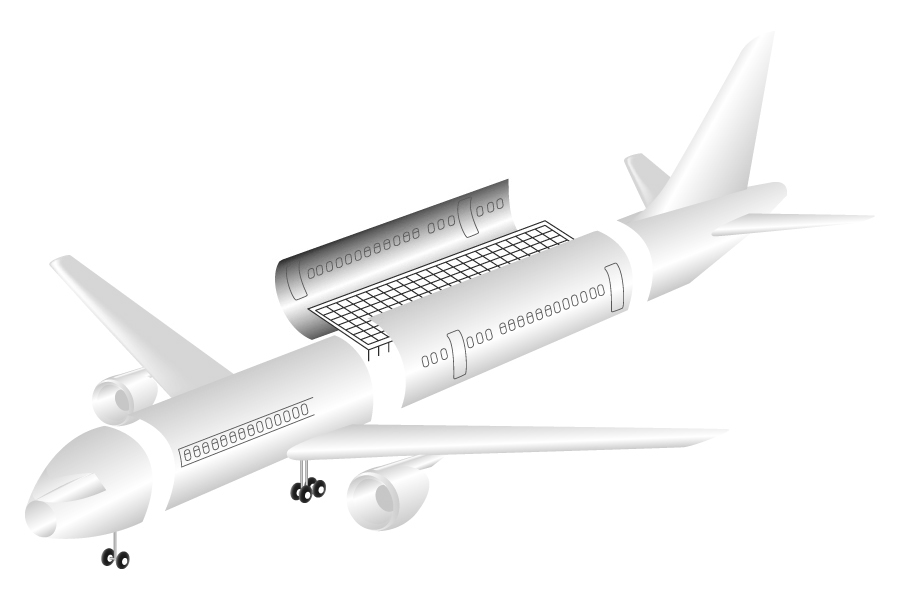

Pre-FAL (section assembly)

What is drilled?

- Assembly of all sections of the fuselage

What is Lübbering's solution?

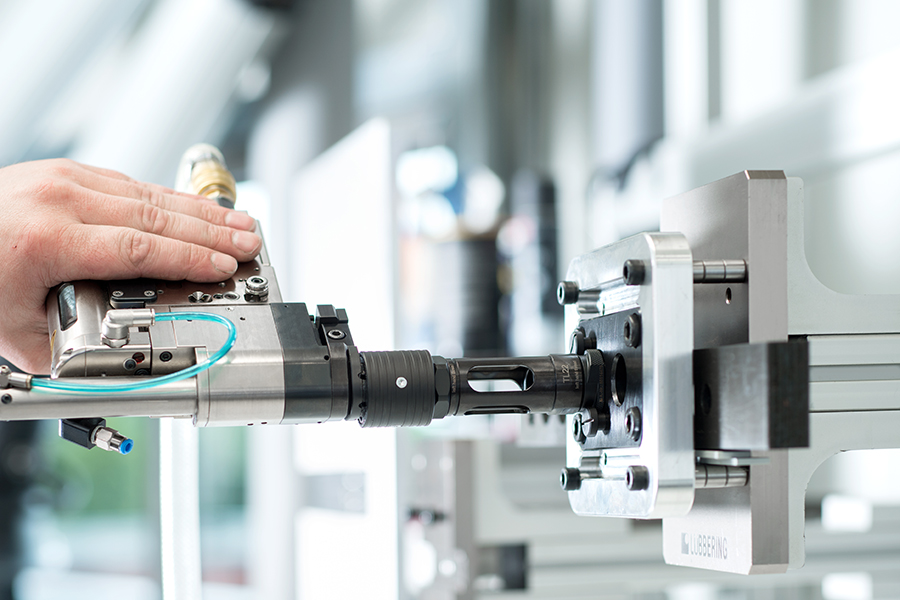

- L.ADU pneumatic Concentric Collet (CC)

- No gaps between thin material layers (stacks) due to high clamping force

- Nose pieces in full surface contact with component guarantees nearly 100% extraction of chips and dust

- Highly effective in dust / chip extraction and countersinking due to full surface contact

back to overview

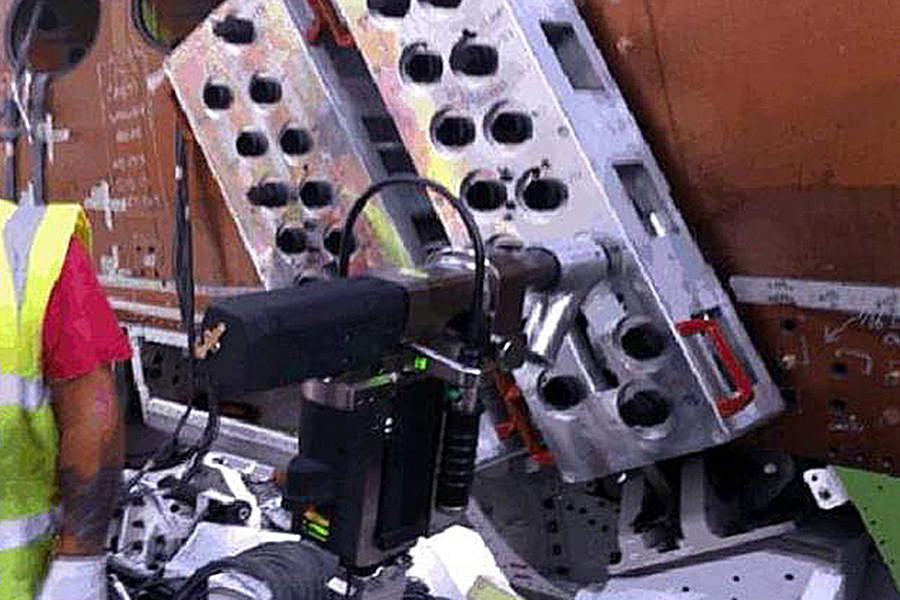

Gear rib assembly

What is drilled?

- For the gear rib assembly, it is necassary to drill holes through the subfloor of the fuselage

- After that the gear rib can be assembled

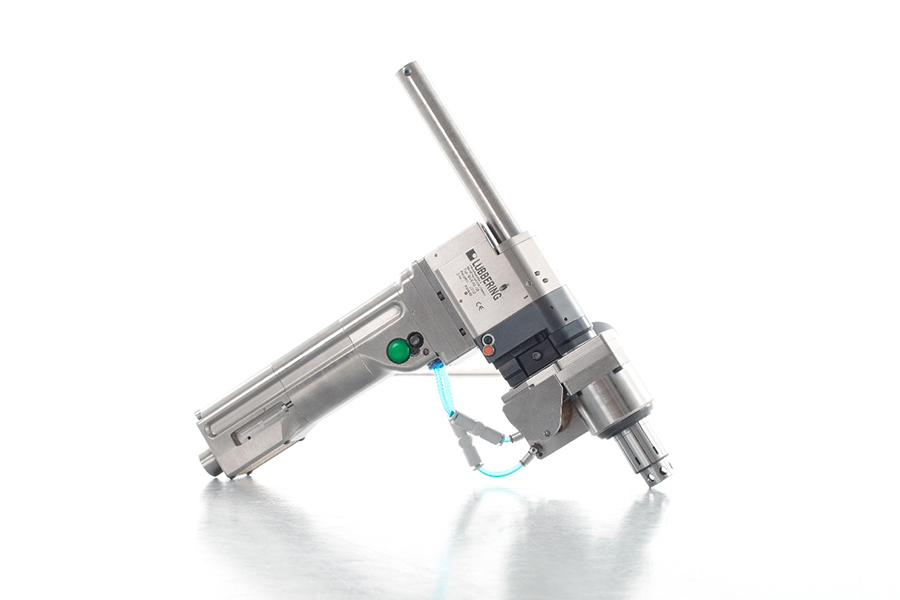

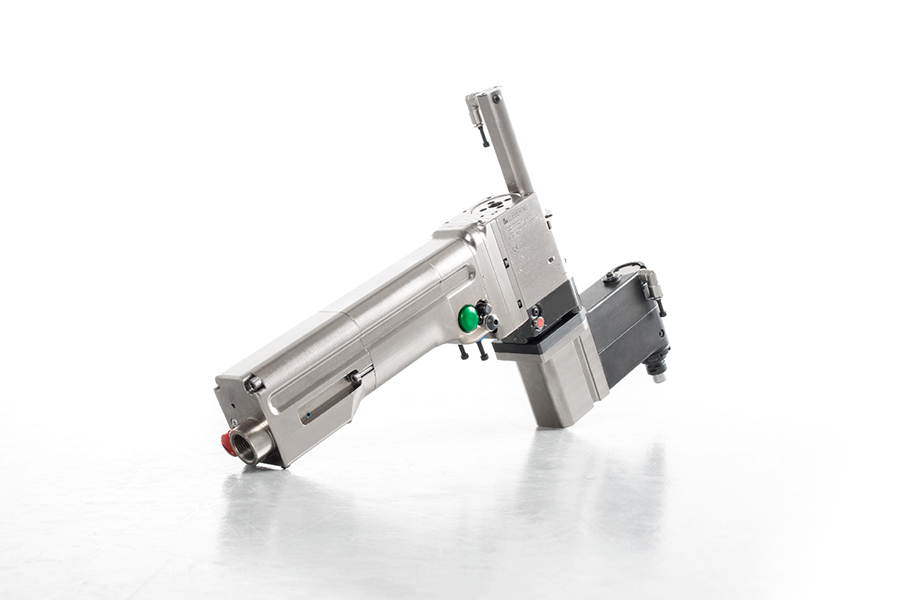

What is Lübbering's solution?

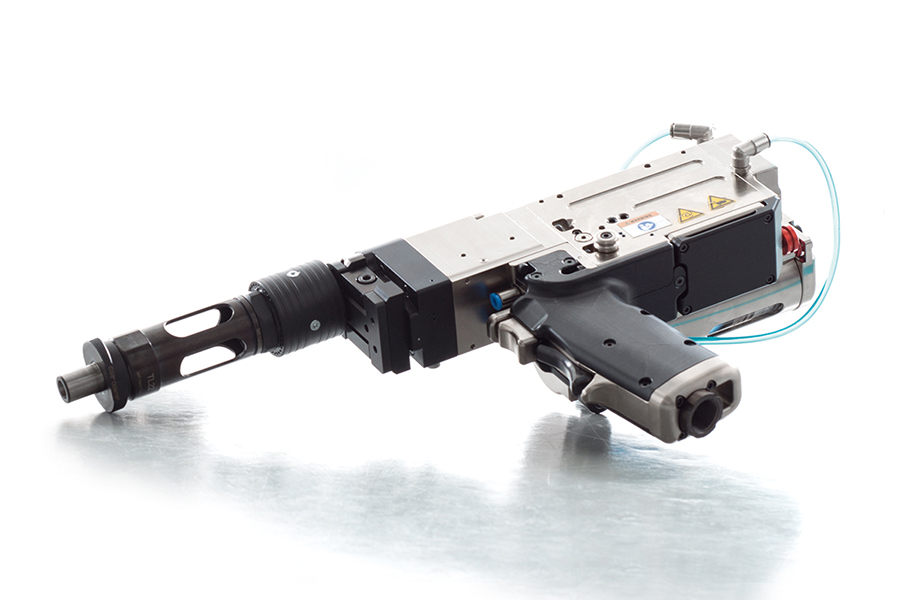

- L.ADU electronic 520 with L.ADU locking system Taperlock (TPL)

- 1st step: 1“ pre-drilling and 1“ ream and countersinking

- 2st step: bolts are sticked into the drilled holes and after that cap nuts are sticked onto it

- The large arm of the fastening tool is needed, because one is not able to hold the cap nut with his own hands and the air plane doesn‘t get damaged

back to overview

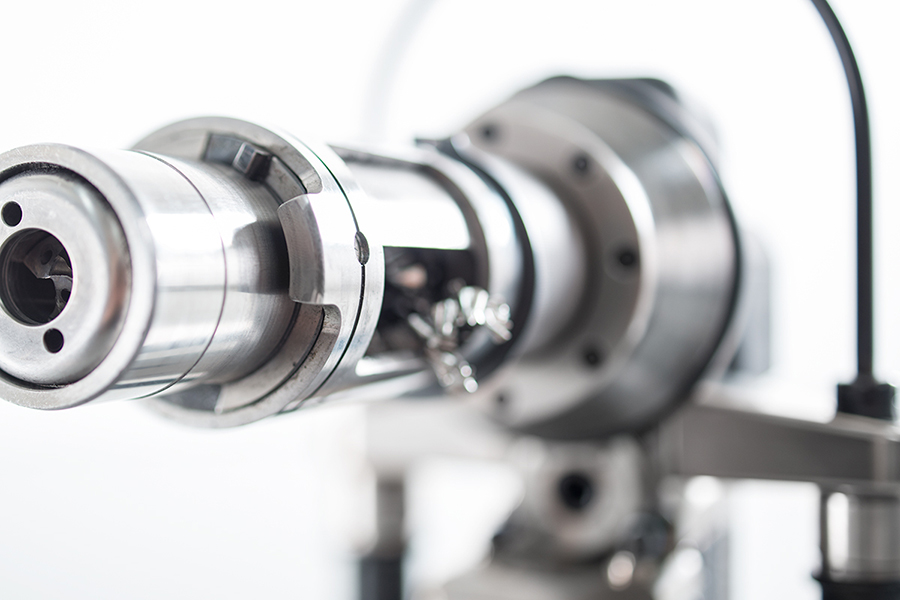

Engine pylon

What is drilled?

- For the engine assembly, it is necassary to drill holes through the junction under the wing

What is Lübbering's solution?

- L.ADU electronic 520 with L.ADU locking system Twist Lock (inline and right-angled version)

- Adaptive Drilling Performance: automatic spindle speed adjustment due to automatic material detection of stacks

- Significant reduction of drilling cycle times through cutter breakthrough sensor

back to overview

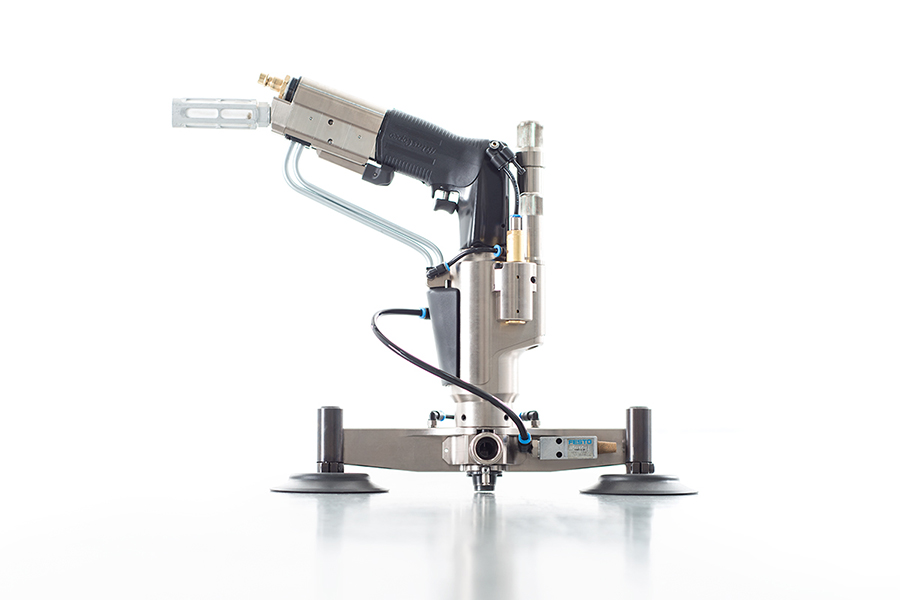

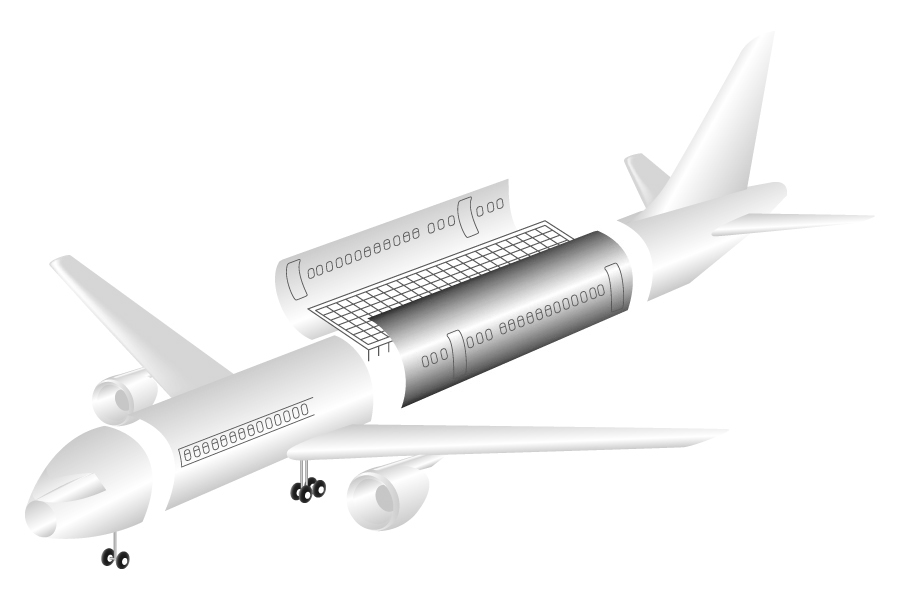

Final wing assembly(FAL)

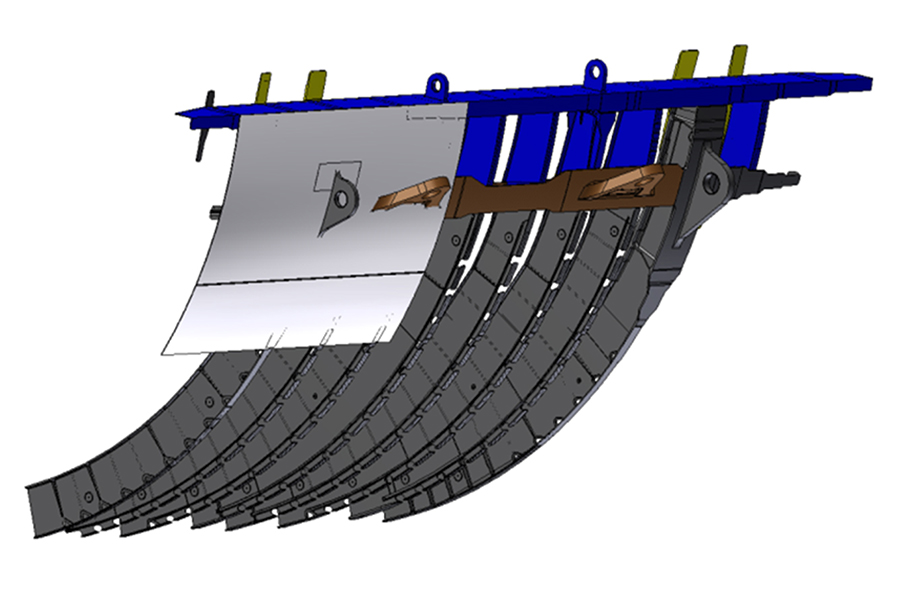

What is drilled?

- The wings are finally assembled onto the fuselage

- To put in the screw connectors, it is necessary to drill the corresponding holes

What is Lübbering's solution?

- L.ADU pneumatic Taperlock (TPL)

- Designed for larger holes

- Can take a high feed force

- One-shot drilling and countersinking: due to the contact between nose piece and surface, it can countersink

back to overview

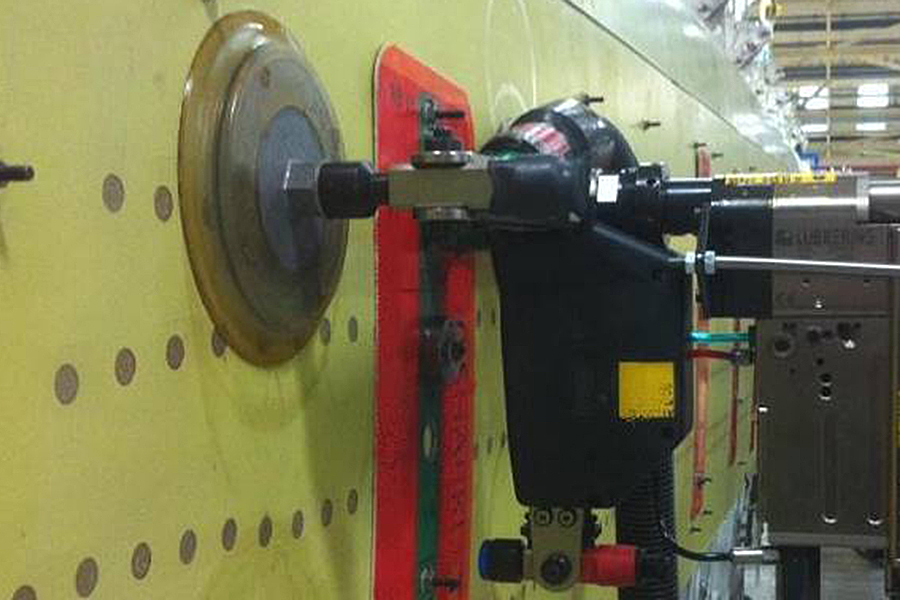

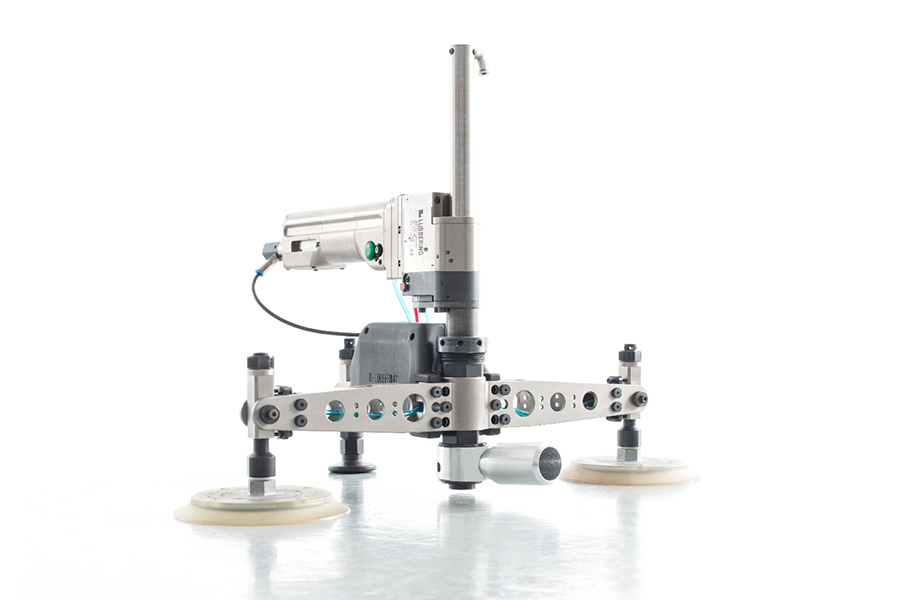

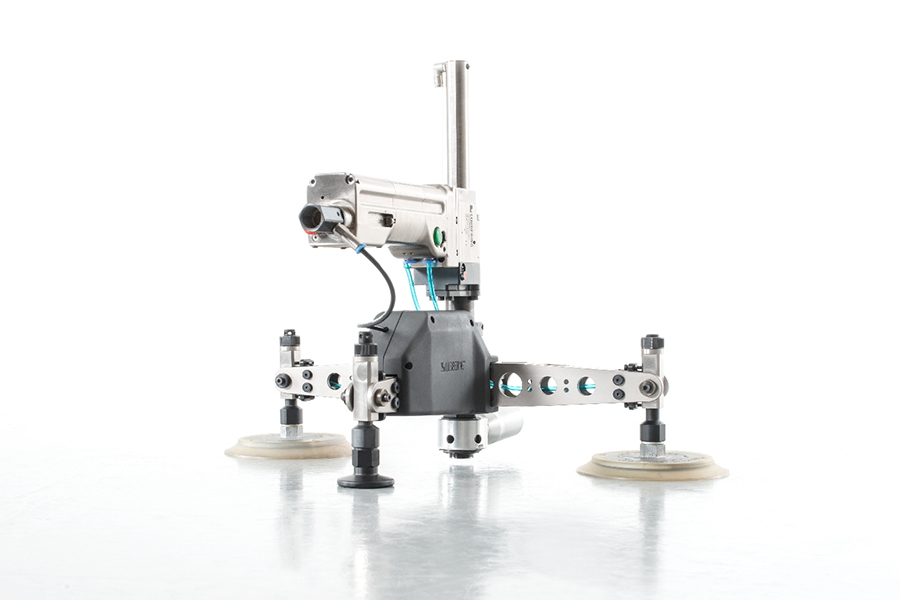

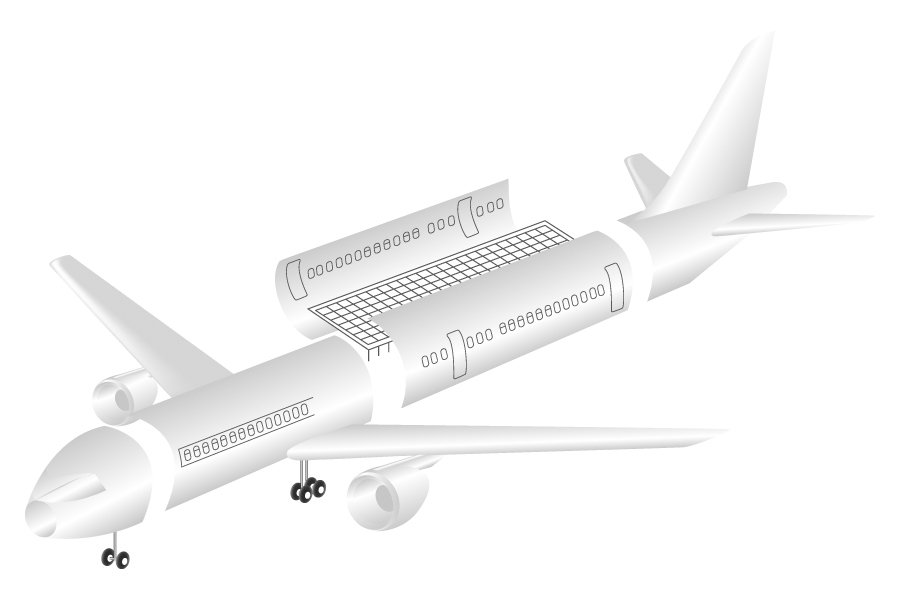

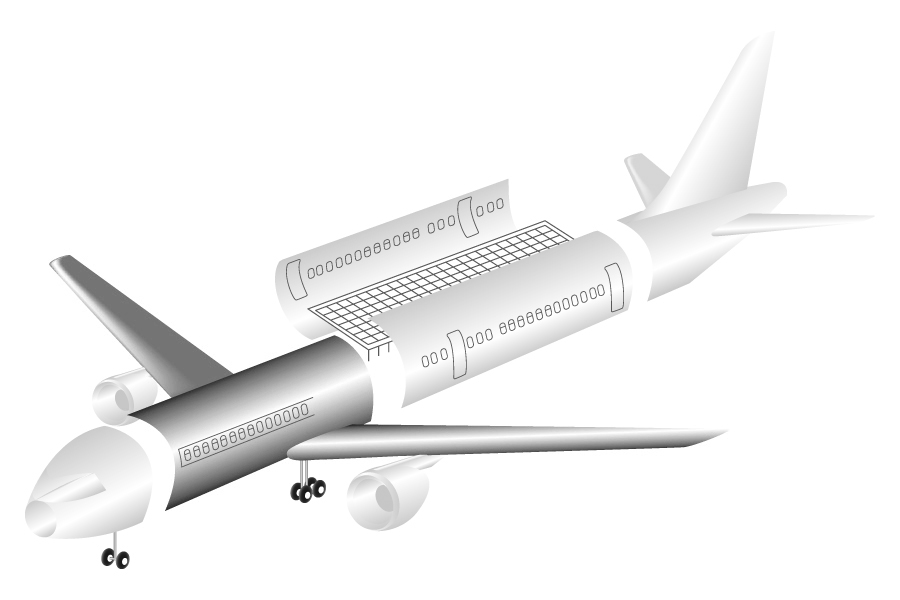

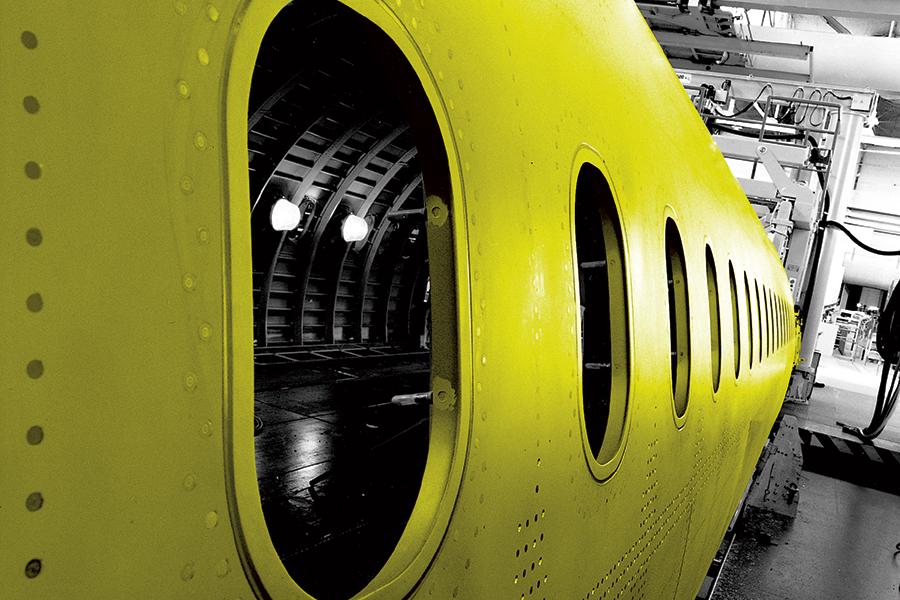

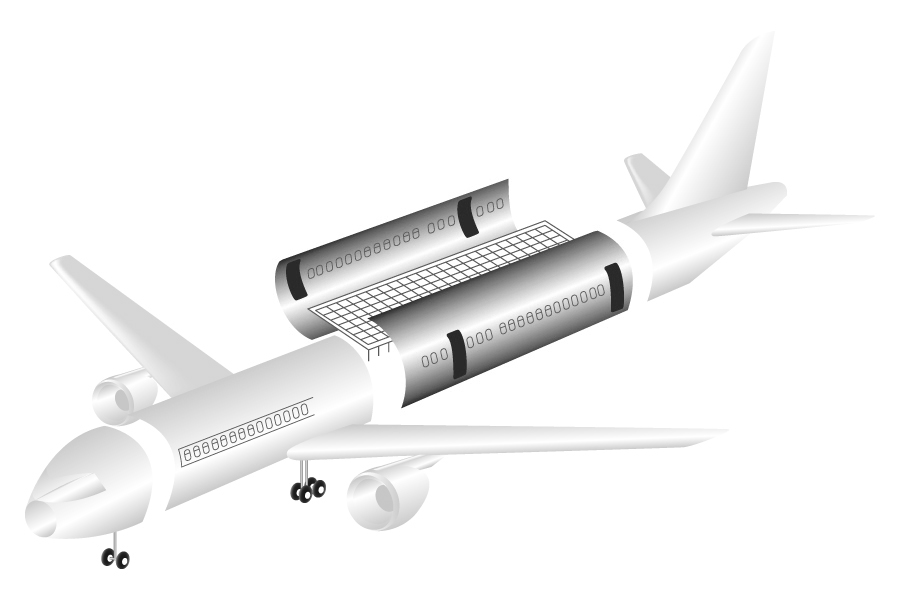

Fuselage outer structure

What is drilled?

- Longitudinal seams

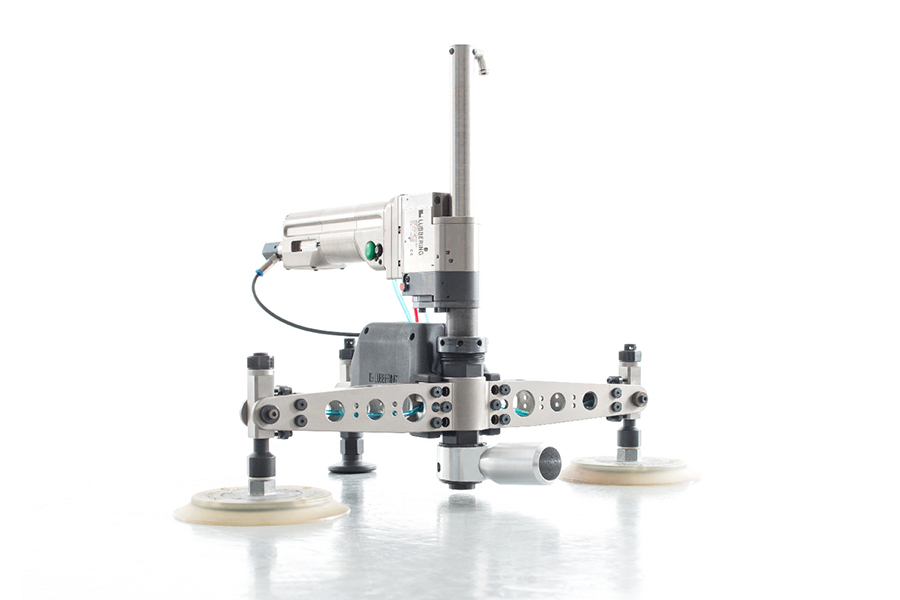

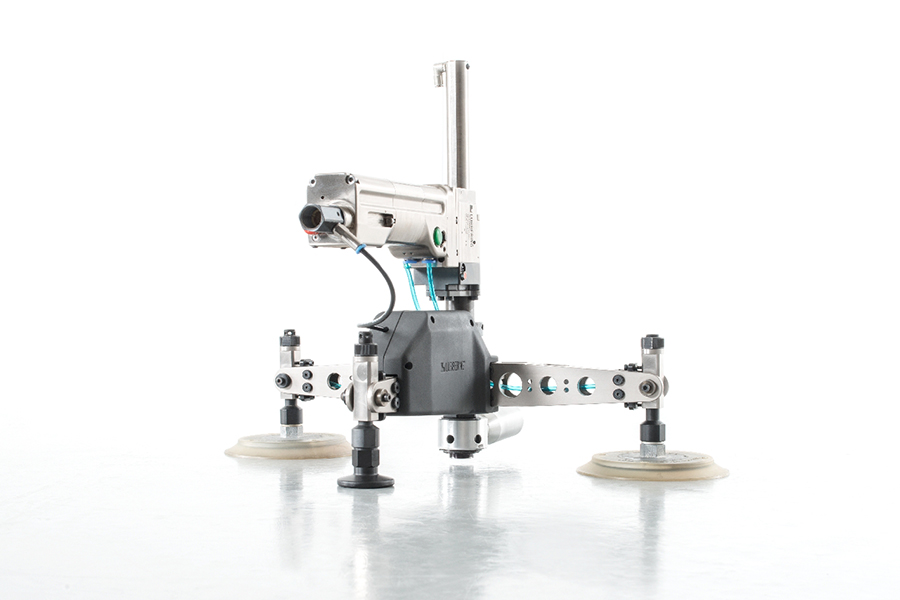

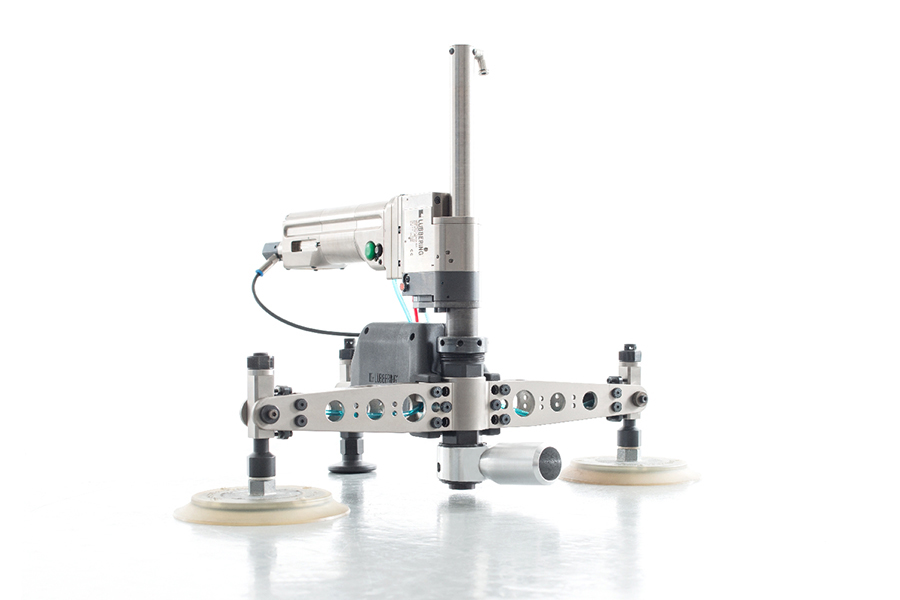

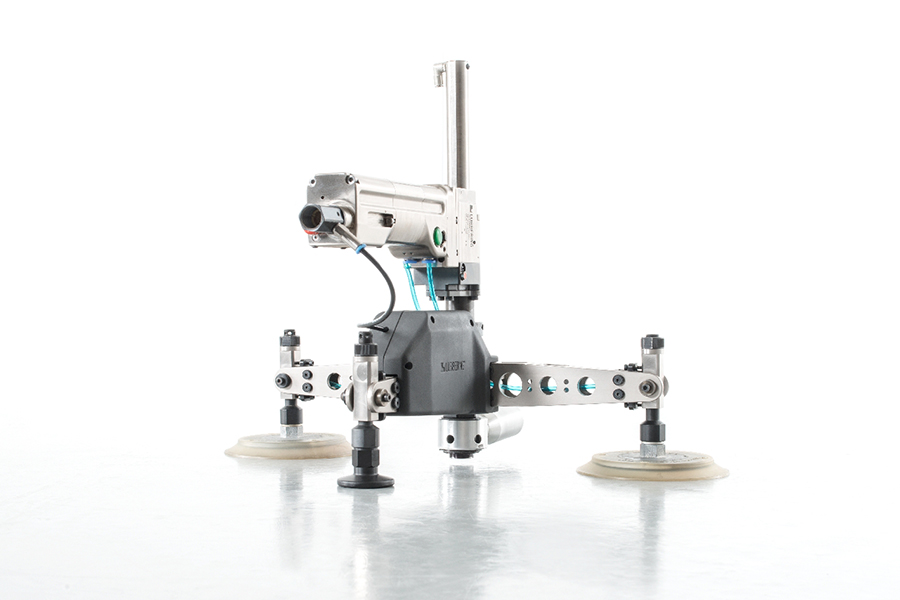

What is Lübbering's solution?

- L.ADU pneumatic Vacuum Traverse (VT) and L.ADU pneumatic HS 60 (High speed)

- Through locking onto the surface via vacuum pads, the drilling machines enable precise drill holes and a secure handling

- Easy positioning through either a pilot cutter, a pilot target or a cheap and simple strip template

back to overview

Fuselage inner structure

What is drilled?

- Pre-shell assembly

- Spar joints assembly

- Floor grid assembly

- Seat rails assembly

What are the difficulties?

- A high clamping force is necessary to drill precise holes through the shell

- A very tight access to the floor grid

- A lot of individual components and series

What is Lübbering's solution?

- Pre-shell assembly: L.ADU pneumatic Concentric Collet (type 55) ensures a high clamping force for all drilling operations

- Floor grid: L.ADU pneumatic Geared Offset (GO) for very tight accesses

back to overview

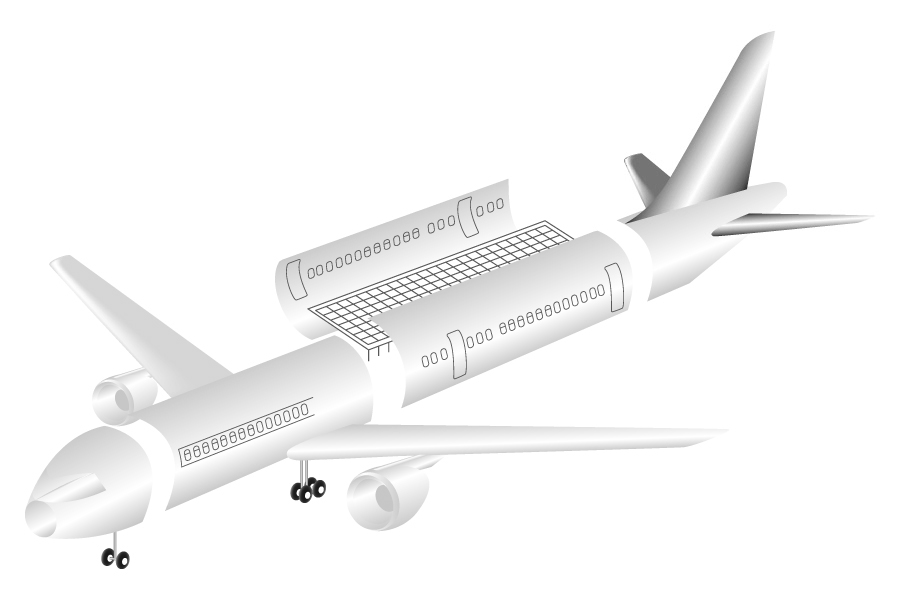

Door surrounding

What is drilled?

What is Lübbering's solution?

- L.ADU pneumatic Vacuum Traverse (VT)

- Locks onto the surface via vacuum pads

- Easy positioning through either a pilot cutter, a pilot target or a cheap and simple strip template

back to overviewersicht

Vertical/horizontal tail plane

What is drilled?

- Drilling holes through the rear fuselage to assemble the Horizontal Tail Plane (HTP) and Vertical Tail Plane (VTP)

What is Lübbering's solution?

- L.ADU pneumatic Concentric Collet (CC)

- No gaps between thin material layers (stacks) due to high clamping force

- Nose pieces in full surface contact with component guarantees nearly 100% extraction of chips and dust

- Highly effective in dust / chip extraction and countersinking due to full surface contact